A warm home is not only an element of comfort. This system really helps to save when paying heating bills. When our legs are warm, then the air temperature in the region of the head can be lowered to 18 degrees, and it will feel completely different.

The author of this master class threw a peculiar challenge to modern guidelines for the arrangement of warm floors. In particular, he did not build a rough screed, but laid the insulation boards directly on the ground, sprinkled with a sand cushion. In the process, some other aspects of the “technology” were deliberately violated, which led to a significant simplification of the construction process and savings on materials and labor.

It is worth adding that the author already has positive experience in the manufacture and operation of such a floor.

In order to build a warm floor do it yourself you will need:

Material List:

- pipe as a coolant;

- mesh with 10 x 10 cells with a wire thickness of 3 mm;

- reinforcement 8 mm thick for reinforcing the base of the concrete screed;

- knitting wire;

- cord for leveling the base;

- plaster beacons;

- bar 20 x 20 mm for the manufacture of supports for beacons;

- tile insulator - in this case, extruded polystyrene foam with a thickness of 50 mm;

- polystyrene for facing the perimeter of the floor;

- adhesive foam;

- plastic clamps for fixing the pipe;

- wood screws;

- cement grade 400;

- crushed stone fractions 5-20;

- sand, preferably quarry - for mortar;

- sand for a sandy substrate;

- plasticizer for warm floors.

Instruments:

- concrete mixer;

- containers for solution;

- shovel;

- grinder;

- wire cutters;

- the rule is plaster;

- Master OK;

- building level;

- a knife for cutting foam and expanded polystyrene;

- home-made mop for leveling the sandy base;

- gun for glue-foam;

- hammer.

Manufacturing process

Step one: supply and wiring communications

Before starting the manufacture of underfloor heating, it is necessary to supply communications to the house and internal wiring. At this stage, the laying of sewer pipes and water pipes is carried out, since it will be impossible to make any large-scale changes after laying the warm floor.

Step two: leveling the base under the warm floor

According to the author’s technology, the underfloor heating system is mounted directly on the ground, whereas in the already classic version, work begins with laying a rough screed.

However, when it comes to rational cost savings for construction, a logical question arises: what is the role of screed in this case and is it possible to do without this expense item. The author decided to take a chance and, from his own experience, test the performance of a warm floor laid directly on the ground.

In this case, the basis for the insulation will be dry soil, compacted during the construction of the house. This is a fertile post, which remained after digging a trench under the strip foundation. Protected from moisture, it retains its density almost unchanged, so drawbacks should not be feared.

Step Three: Preparing the base for underfloor heating

Before laying polystyrene foam, the site must be leveled. The author leveled the plane on top of the foundation. The process is easily controlled with a cord fixed in the center of the room.

For more precise alignment, the author poured a layer of sand - a kind of sand cushion of small height. You can even out the surface of the sandy base with the help of a home-made “mop”.

The author uses extruded polystyrene foam 50 mm thick as a heat-insulating material. Elements of the insulating layer are attached to the castle, forming a monolithic base.

Step Four: Lining the perimeter of the underfloor heating

A concrete slab of a warm floor should be able to expand and narrow freely when heated and then cooled. Usually for this purpose, a damper tape made of foamed polyethylene is laid along the perimeter of the wall. The author went the other way - he used the usual white foam of low density.

Strips of 2-cm thickness were pasted by the author around the entire perimeter using glue-foam. This solution has several advantages compared to the damper tape. Firstly, an additional layer of insulation at the end of the plate reduces heat loss of the warm floor through the wall. Secondly, the foam edge will serve as a kind of beacon for the rule around the edge.

Step Five: mesh reinforcement and pipe laying

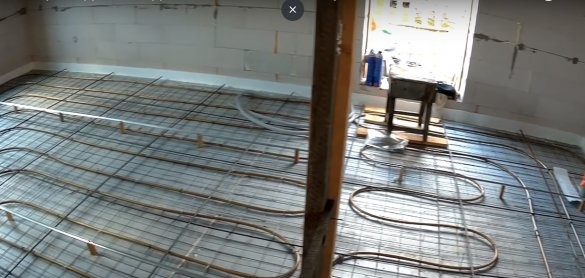

On top of the polystyrene foam, the author laid a grid with a cell of 10 x 10 mm and a wire diameter of 3 mm. It additionally reinforces the base of the concrete slab and is an excellent basis for fixing the underfloor heating pipe.

A pipe with hot water will heat the floor. In fact, it is part of a water heating system. Despite the fact that all of it is powered by electricity, the author nevertheless gave preference not to a heating cable, but to a pipe with water. The choice is primarily due to the fact that such a system looks more reliable, because it consists of only one heating element - a boiler.

The pipe was laid with an interval of 30 cm. Experience has shown that this is enough and the concrete slab heats up evenly. Of course, we are talking about a house with good insulating properties. If the house is not sufficiently insulated, a smaller step will be required when laying the pipe.

The pipe snake is laid from the outer walls and gradually approaches the center of the room. The hotter heat carrier is located closer to the perimeter of the house and, cooling, approaches the center. So, the house warms up with the greatest efficiency.

Step Six: Reinforcement with Armature and Installation of Beacons

Since the floor is poured with a solid and rather massive slab 10 cm high, it was decided to reinforce it with reinforcement. For this, the author used a reinforcing bar with a diameter of 8 mm. The fittings are laid crosswise on a cross with a step of 60 cm, and its details are connected by wire.

Please note that the fittings are laid on top of the pipe. Thus, the reinforced frame will be somewhere in the center of the concrete slab.

As racks for lighthouses, the author used a wooden rail with a cross section of 20 x 20 mm. In polystyrene foam, he cut square holes and drove stakes directly into the ground.The absence of a rough screed allowed the use of such almost free and very convenient mounts.

To align the base of the pegs, the author used a cord. Plaster beacons are fastened with ordinary wood screws and mounted in two counts.

Seventh step: pouring a warm floor

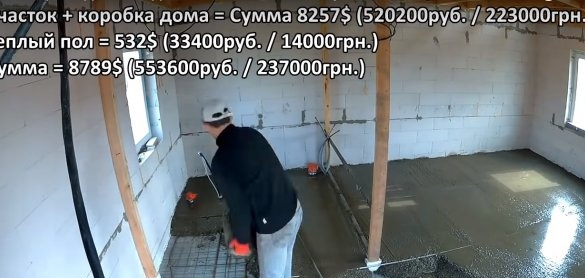

The author made the mortar for the concrete floor on his own. In total, about 3 cubic meters of concrete was used up, for the laying of which a team of amateurs of 6 people spent only 6 hours.

Before starting work, the author brought in 7 tons of gravel of fraction 5-20 and the same amount of river sand, as well as 30 bags of cement grade 400. For one batch of concrete consists of half a bag of cement, two buckets of sand and three buckets of gravel. A special plasticizer for a warm floor is also added to each batch.

A floor heating plate is flooded with a thickness of 10 cm. Its main task is to accumulate and effectively transfer heat from pipes with hot water. This is due to the high content of crushed stone in the solution.

In total, as of 2019, $ 532 was spent on floor production with a total area of 30 square meters. m