The all-terrain vehicle with all-wheel drive and the design of the tipping frame was made in just a month and a half. The author made this all-terrain vehicle on order. The all-terrain vehicle was created under clay roads and rugged terrain. In many ways, the design of the all-terrain vehicle depended on the wishes of the customer, so the car turned out to be a little specific, although it is possible to make improvements to increase its versatility.

To create this machine, the following parts, materials and assemblies were required:

1) tires from nine ton carts, peeled.

2) bridges from the car Niva 2121

3) transfer case also from the cornfield

4) internal combustion engine about car oka

5) steering rack from vaz 2109

6) a metal profile in sizes 60 to 40, 40 to 40 and 20 to 20

7) the steering knuckle from the UAZ car

Let us consider in more detail the stages of creating an all-terrain vehicle and the main components of its structures.

Since the grinding of tires and the manufacture of disks for them is a rather lengthy process, the author ordered their manufacture from one of the contractors.

Below are photos of how all-terrain vehicle wheels are made:

Wheel assembly:

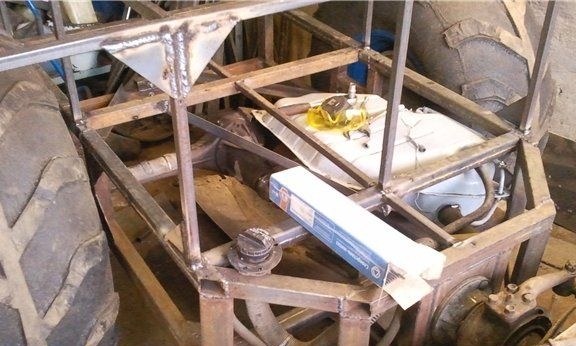

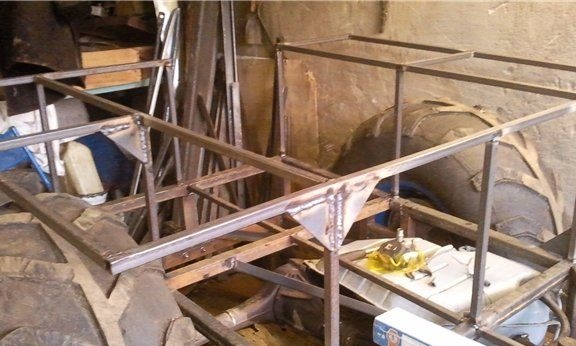

The author himself decided to start manufacturing an all-terrain vehicle frame; for this, welding and a metal profile pipe in sizes 40 by 40, 20 by 20 and 60 by 40 were used:

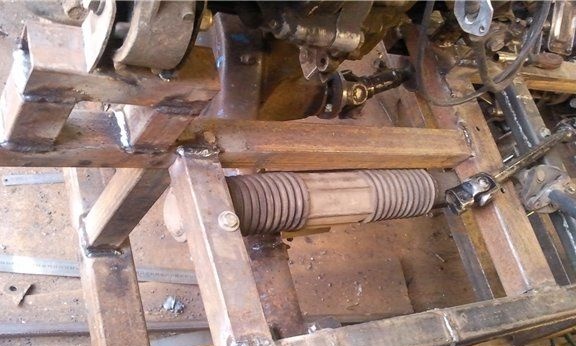

The node fracture of the all-terrain vehicle frames was made by the author according to the scheme (uvat). That is, to create a fracture node, a standard rotary fist from Oise was used.

Below are photos of the site itself:

After which the author began to install the brake system on an all-terrain vehicle. Brakes were installed on the front wheels, with the main brake with a vacuum from Oka.

An engine was installed. Transmission:

Other photos of all-terrain vehicle structural elements:

Installed steering and pedals:

The all-terrain vehicle turned out to be quite heavy, but for the most part this is due to customer requirements. The profile pipe for the frame was taken with an excessive margin of safety, although it was quite possible to manage with a thickness of 4 mm. Another desire of the customer that influenced the mass of the finished off-road vehicle was the fact that the car was sheathed with sheets of galvanized steel, although it was possible to make plating of aluminum, which would be much easier.

Creating a cabin frame:

As a result, the mass of the car turned out to be about 900 kilograms. How the all-terrain vehicle will behave on water with such a mass is not known, since the task of building a floating all-terrain vehicle was not before the author and the corresponding tests were not carried out.But most likely buoyancy is not the best side of this machine and it will plunge heavily.

The clearance of the all-terrain vehicle is enough to safely ride over bumps and holes.

And below is an illustration of how the clutch of an all-terrain vehicle was spliced:

The gearshift was also installed:

View inside the all-terrain vehicle cabin:

As can be seen from the photographs, the lower parts of the semi-frames were mounted below the bridges of the all-terrain vehicle. If the task was to make a floating all-terrain vehicle, it would be better to make half-frames hermetically by boats. Now, the resulting bumpers will not be the best way to manifest themselves in mud traps.

But the author made this design due to the fact that when installing bridges under the frame on the cardan shafts, a critical angle was obtained, since the frames consist of an upper and lower frame. The fracture knot is located between these subframes and the angle is too large.

Of the possible modernizations, the alteration of frames under one level and the increase in clearance by installing bridges under the frame, at least on a spring suspension, are considered.

The boat structure was not made, since the place where the customer will operate the machine without swamps and water, the main part of the routes consists of clay, the most difficult conditions are clearings in the forests.

Photos of the finished all-terrain vehicle. after plating and painting with galvanized steel

The author of the all-terrain vehicle: Alexander with the nickname "alekcandep.brat" on the site of from the city of Vologda.