Most land owners try to make their work more optimized. A very useful and convenient know-how in its time was the Fokine cutter - an ideal assistant to gardeners and gardeners. The plane cutter, rightfully, has become an indispensable tool in all types of agriculture. With the help of a plane cutter, the work on processing and caring for land is greatly facilitated. A plow cutter quickly and efficiently eradicates weeds and loosens the soil, and digging the ground is replaced with a plow cutter.

But Fokin’s plane cutters are much more expensive than usual choppers,

therefore, craftsmen make these tools on their own.

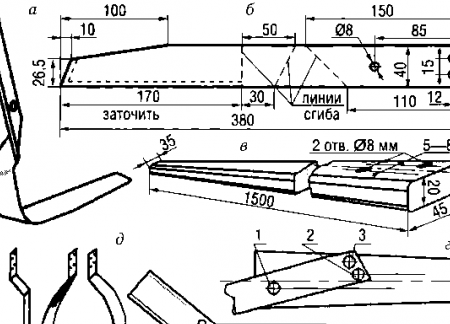

For the manufacture of a plane cutter, it is necessary to select a metal strip up to 40 cm long. Then bend points are marked on the strip, according to the dimensions in the drawing.

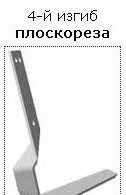

Clamp the metal strip in a vise and bend it with a hammer in four steps.

Step 1.

Step 2

Step 3

Step 4

It will turn out a curved piece of iron, which is still far from the present product. Drill 2 holes in the area that will be attached to the wooden handle.

Then the tip of the working area of the plane cutter is cut off at 45 degrees. The resulting sharp end is very convenient to loosen the aisles and remove weeds.

We approached the most important - tool sharpening. The correct sharpening will determine how easy it will be to work with a plane cutter. Plane cutters are usually double-edged, which means that it is necessary to sharpen the tool from two sides, not forgetting the cut at the end of the working area, it is also sharpened. The need for sharpening the Fokin plane cutter will be needed in a few years.

The upright tool should be about 20 cm below the shoulder. From this, the length of the cutter is calculated.

Carefully screw the cutter to the handle with screws or bolts

and the tool is ready for use!