Exercising is now again in fashion. But it’s not always possible to visit gyms. In our fast pace of life, there is not always time for this. Therefore, some create sports rooms at home. To at least somehow manage to keep fit. Therefore, I bring to your attention a homemade bench for a bench, which two brothers made independently.

For the base, a Ø57 pipe was taken. By welding, they gave it the necessary shape. The same pipe was welded to the legs. For further convenience when working, until the base is rigidly bonded, a transverse strut was welded to support the parts.

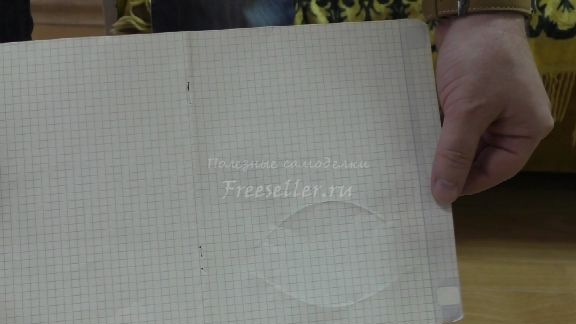

In order to close the holes, a paper stencil was used, which was applied to the workpieces and a part was obtained of the shape we needed.

Using the template, we transfer this stencil to the pipe Ø57 and outline it. Cut with a grinder.

The workpiece is ideal for closing openings. We weld it and clean it.

Since the transverse screed is no longer needed, the base is on its own, then we remove it.

For further work, we will need swivel joints for fastening parts. Their authors make a strip of metal. Drill holes are made in them with a Ø 10 drill.

The basis of the sunbed and bench is made of profile. Select the desired size and weld the rectangular parts, as shown in the photo below.

We focus on the bench. To do this, make a moon cutout in the tube and weld another part of it. The item should be in the shape of the letter "T"

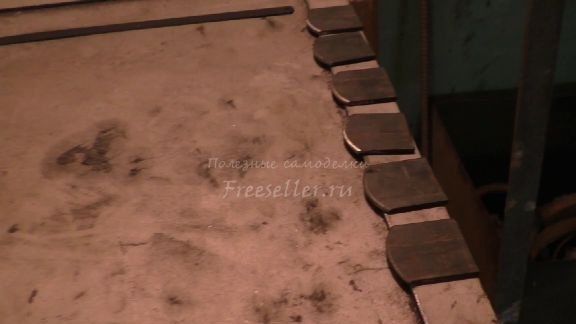

Now we make stops from the pipe to maintain and adjust the inclination of the sunbed and bench. We cut the pipe into small workpieces and cut across into two unequal parts. Welded to the base legs.

Then we clean all the details so that there is no rust before painting.

Degrease and primer all parts of the bench. If you are painting and do not want to stain the floors, then either spread something or wet the floors so that the paint does not stick to them and it can be easily removed after finishing the work.

Dry the details.

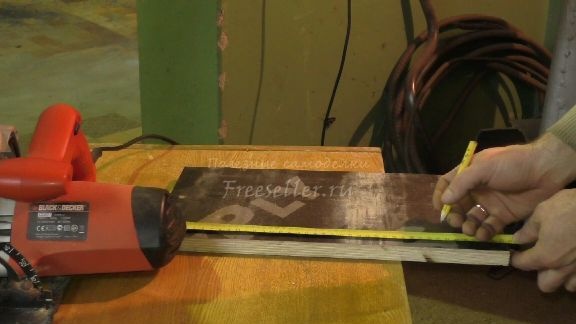

Next, cut the plywood to the desired size in order to lay it on the lounger and seat. Corners do not leave sharp, squeezing them.

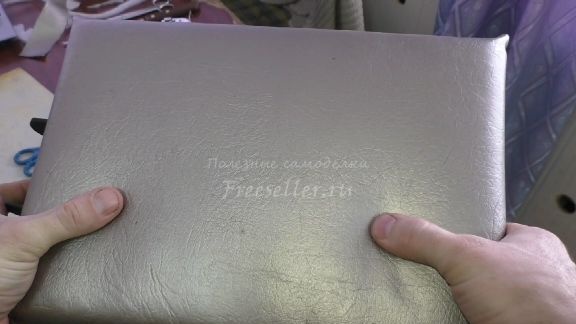

We manufacture plywood sheathing from an 8 mm substrate in two layers. Pull this material on the sunbed and seat. Fasten with a construction stapler and staples. We twist and fasten the material. In the metal base, holes are drilled for self-tapping screws and plywood is fixed on the inside.

And the last stage is the assembly of all components into a single design. And here is the result:

Now you can not rush to the gym. At home, at any time convenient for you, you can enjoy working out!