The principle of operation of the lathe is the same, but the method of its manufacture is different for each master. Lathe to the author homemade needed when he decided to restore the old spinning wheel. The spinning wheel lacked some parts and for their manufacture the author made a lathe.

Tools and materials:

-Plywood sheet;

-Engine;

-P-profile

-Bearing;

-Bolt;

-Nuts;

-Washers;

-Case air vent;

-Fasteners;

-Wooden bar;

-Welding machine;

- Jigsaw;

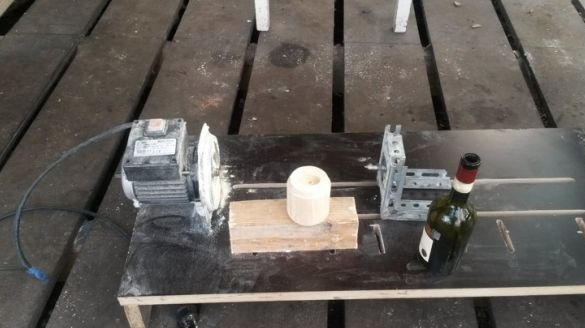

For the bed the author used plywood 22 mm thick. He made the length of the bed so that it would be possible to sharpen parts up to one meter long. I installed the engine on the bed and marked the mounting points and the center line.

Drilled holes for mounting the engine. Marked guides for the tailstock. Using a jigsaw, I cut them out. I screwed the legs on the sides of the bed.

It was decided to make the tailstock from the P-profile. The headstock, in this case the engine shaft, must be at the same height and axial with the tailstock. Measured the height from the bed to the center of the motor shaft. Welded mount grandmother. I installed a bearing in the center.

I installed a wooden plug in the inner race of the bearing. He put a washer on a pointed bolt. The bolt inserted into the hole in the cork, put on another washer. He tightened the nut on the bolt, tightened it.

Set the tailstock in the guides. The grandmother is fastened with bolts with a lamb. Screwed the engine. The author used the engine from a circular pump.

A hand made a bar. Cut the transverse cuts for mounting the handcuff. The author made a turning chuck out of a bronze air vent housing. Sawed, using a grinder, in the front of the air vent “crown”. Secured a chuck on the motor shaft.

Homemade lathe is ready.