This article will talk about how to make special "tenacious" coasters, which can be useful during various carpentry work when creating new homemade.

These coasters are wooden blocks that have recesses for securing a special material with high adhesion to the surface. Due to the use of such blocks, the workpiece placed on them not only does not move when it is processed using a grinding machine, or when working with a circular saw, milling cutter, but it also lifts the workpiece above the work table. Thus giving more opportunities for work, improving the accessibility of the part and ease of use of tools when working on it. As a result, placing the workpiece on such supports can completely focus on the work performed and not be distracted by additional fixing parts in some types of processing.

Materials and tools for creating “tenacious” stands:

- wooden block

- special mat with non-slip surface

- a circular saw

- iron ruler

Description of the manufacture of coasters:

Step one: cutting wooden blocks under the base of the stand.

First, a wooden block is taken, on which grooves are made on both sides along the entire bar with a circular saw. The depth of the grooves is 18 mm (this depends on the thickness of the coating that you will use in the next step), they are located on the edges of the future stand. They are clearly visible in the above photographs. After that, billets are sawn from this bar: two 65 mm long and two 130 mm long.

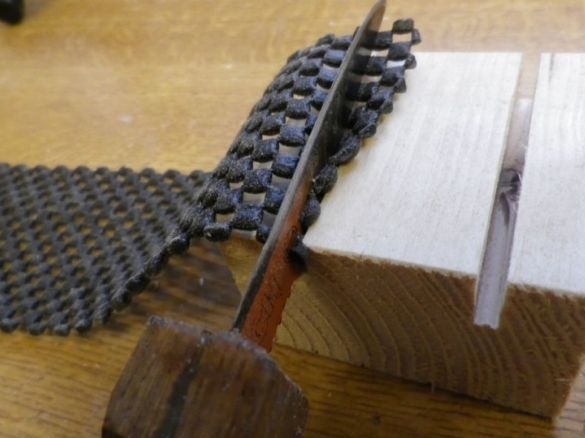

Step Two: Create Improved Grip

After the base for the stands was made, it was time to cover it with a special tenacious coating. To do this, take some kind of "non-slip" rug, these are often sold in specialized stores, or you can order one via the Internet. Strips of a size slightly larger than the surface of the base under the supports are cut from this mat. Before cutting, you need to check that the mat fits tightly into the groove of the workpiece. Then with a metal ruler, knife, or other flat fixtures the cut mat is tucked into the grooves of the workpiece.

Step Three: Testing the stand.

After the previous steps, we get a ready-made stand, which must be tested before work. It is important to ensure that the edges of the coating do not slip out of the grooves of the workpiece, since safety depends on this when working with these supports. If the mat slides, you should either remake the workpieces to the same, but with narrower grooves, or use a thicker mat, or securely cover the workpiece with any other available methods.

Then you can safely begin to work using such coasters.

Video of the manufacture and use of tenacious stands in work: