After the car owner has installed a short-stroke backstage, the gearshift lever stroke is much shorter, because of this, more effort is required when switching. The way out of this situation is as follows: you need to make the gear knob higher. Thanks to this, driving a car will be much more convenient.

In any case, if such an improvement does not please the owner, you can always return to the original version. No welding work is needed here.

Materials and tools for homemade:

• gear knob of a new sample from LadaPriora;

• case for gear knob;

• file;

• electrical tape.

The process of manufacturing an elongated handle

Step 1. Dismantling the stem

In this case, the rod from the rack of the Lada will serve as the extension of the handle. The cartridge is disassembled and everything necessary is obtained from it. The edges of the nut are stitched and clogged into the gear lever itself. The author decided to replace the handle with a housing from an LED flashlight. As a finish, a vinyl film was used.

Step 2. Leverage Extension

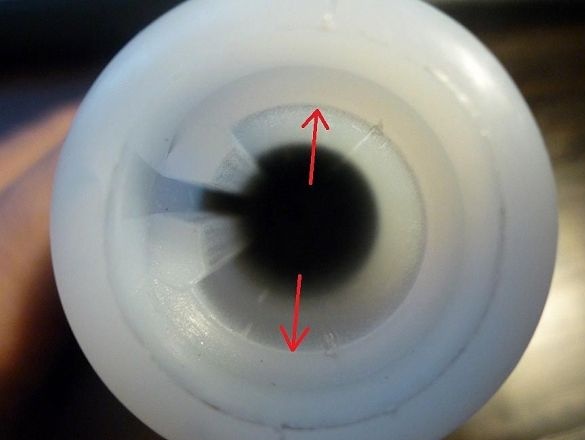

Then you need to find a tube of a suitable size that can fit tightly on the standard lever and the gear knob itself. We look at what size is needed, try on and cut the tube in the right place.

Step 3. The last stage

The tube and gear lever can be wrapped with electrical tape for better bonding. A casing is put on, the edge of which must be covered with a plastic ring.

Conclusion

This design is especially good in that you can independently adjust the length of the handle, the larger the tube, the greater the height of the handle.