Periodically, it becomes necessary to measure the length of the curve line. For example, when working with a pipe bender, or in the manufacture of decorative elements ("curls") for cold forging, the material must be cut to a certain length to make the part. And how to find out that length? ))) So you have to figure it out approximately, cut off with a margin, and then, after manufacturing, cut off and throw away the excess ... So the idea arose to acquire a curvimeter.

The network has a lot of descriptions of the simplest such device, which does not even have any scale. The essence of his work is that the impeller does not rotate freely on the axis, but is screwed onto the axis by means of a thread. The master turns the wheel all the way, and then rolls it along the curved line on the sketch of the part. In this case, the wheel is turned on the thread for a certain number of revolutions. It is enough to turn the device over and roll it with a wheel all the way along the ruler, or tape measure - at the point at which it will be wrapped again until it stops and you need to read the readings. This will be the length of our curve line.

Here is such a curvimeter and I decided to collect ... I decided I decided, but my hands didn’t reach .... And so, being at my construction site, I decided to make a garden bench from the remains of building materials. I drew a sketch ... And again, before using the pipe bender, it would be nice to know the length of the section of the profile pipe, so as not to cut too much ... I thought ... Yes, and decided to collect the curvimeter first ... Construction is, of course, not a workshop but there was everything necessary ... Yes, and devicesomething primitive - you can collect it and "on the knee".)))))

So what I needed:

1. Clamping nut from angle grinder.

2. The handle from it is the same.

3. Trim stud M14.

4. Nut M14 (2 pcs.)

5. Scrap metal strip 25 to 4 mm.

I have long decided to use the nut from the "grinder" as the impeller - this is a finished wheel with a thread inside! I also decided to take the handle “grinder” - it makes no sense to handshake something myself, if there are ready-made solutions! In addition, I have enough of this good - in the workshop there is a box with the remains of a power tool! Periodically, these residues act as "donors", only ... Nuts and arms do not break (in the angle grinder, the rotor and gearbox usually fail), and therefore there are a lot of them.So, "with a black sheep - even a tuft of wool!" )))))

But this box is in the workshop. I’m at a construction site ... And therefore, without further ado, I dismantled one of my grinders!

Then I will complete it! Fortunately, the elements are the same standard !!!

So, there is a wheel! As you know, on the spindles of all grinders, the thread is the same - M14. Therefore, it is necessary to use a stud with such a thread as the axis. I used this pin in the manufacture of the carriage and vice of my cutting machine, so I had trimmings.

For the manufacture of the bracket, in which the pin axis will be mounted, I used a 25 mm strip, a piece of which I found in my scrap metal.

Cut off about 20 cm, and bent it, leaving the middle part about 6 cm long. (I proceeded from the length of the studs. It would be nice to do it in a vise, but the vise remained in the workshop ... And so I slightly sawed the grinder and bent it with a hammer, using a sledgehammer as an anvil ... (But so what! ... But then "now" and not "later" ...))). The result is such an arm:

Noting three centimeters from the "back", I drilled holes in each of the "horns", 14 mm in diameter, using a drill and a step drill:

On the “back” I drilled a hole with a diameter of 8 mm for fixing the handle (All the handles of small “grinders” have an M8 screw. An exception is the Bosch grinders, the handles of which have an M10 thread). I worked all the same step drill. (A convenient thing, I tell you ... And you can drill a huge diameter with a household drill, and you won’t break it, no matter how hard you try!)))). True, there are drawbacks - the material is not thicker than 5mm, and difficulties in sharpening ....

Further, I cut off the excess with the grinder, and rounded the other, using the emery-petal circle. He gave a more finished look, so to speak:

All. You can start assembling.

Initially, I thought just to weld the stud to the bracket. “Drop” on both sides, and that’s all ... But, during the assembly process, I noticed that in full speed my curvimeter goes a little more than three meters. (By chance, it happened so roundly))). Therefore, I decided to fix the stud in the bracket with nuts. Then it will be possible to adjust the full stroke length accurately! It is unlikely that I will ever measure something longer than 3m, but .... what if ?! ))). Let this option be - you roll it all the way, turn it over, and roll on, knowing that you turned it exactly at three meters.

On each side it was necessary to screw on two nuts - one inside the bracket, and the second to clamp the outside ....

The design was very cumbersome (M14 nuts are not very small))). And I decided to just cut two nuts in half. (I don’t know what affected more - the bulkiness of the design, or the fact that I only had three ... One was missing!))))

..Since, as I said, I did not have a vise close either, so I decided to use a hairpin. He screwed the nut a little bit, a couple of turns and locked it second. Then I marked it halfway, using the eye as a vernier caliper, and the nail as a thickness gauge)))):

And he cut it in half, holding a stud with nuts with one hand and a grinder with the other. Sorry, I didn’t have a third hand for the camera)))):

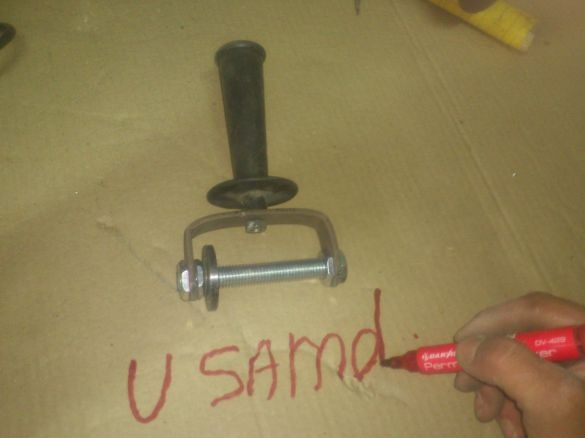

All!!! The curvimeter is ready;

STOP !!!! .... Not ready yet !!! Need to paint! I disassembled it, sprayed it with a spray can, pre-heating the metal with a hairdryer (It dries very quickly).

Now ready:

Stop!!! Again the "cant" !!!! The name of the site with an error wrote ....

Okay, redo it.)))))

True, I didn’t start to do that bench that evening.)))). I played with a curvimeter.)))). Nothing! There will be another day off ....

... I will add, two days later. Thanks for the advice in the comments. Here is a short video review: