If you are forging ancient things such as swords, medieval stilettos and other kinds crafts, you will need such a thing as a small forge. In this article I will tell how one author made such a forge himself out of a chair and refractory brick. Homemade good in that it is disassembled, the chair is folded, and the upper surface is removed and transferred to where it will not interfere.

Materials and tools for homemade:

- old metal folding chair;

- a baking tray (or other sheet metal to create a heat shield);

- refractory brick (the author bought two pieces);

- a piece of steel pipe (for air supply);

- steel brackets and two brackets (for supporting bricks);

- self-tapping screws;

- hair dryer (for air supply);

- pliers;

- drill;

- screwdrivers;

- Bulgarian and more.

Forge manufacturing process:

Step one. Chair preparation

Modifying a chair or not, it all depends on what kind of seat and back it has. The author remade them on flat wooden ones. For reliability, sheet metal can be used instead of boards.

Step Two Fire shield

To make the shield, the author used an old baking tray. In the pallet, you need to cut out two grooves in which the pipe will subsequently be installed. The author made these grooves using a hacksaw and scissors for metal. If a sheet of metal is used flat, then nothing needs to be cut out here.

Step Three Making a pipe for air flow

Due to the fact that coal will create a very high temperature, the pipe must be steel and have a thick wall. The author found for such purposes a galvanized pipe from a construction store, but this is not the best choice, since zinc emits harmful gas when heated.

The holes in the pipe are ¼ inches in diameter and 2 inches apart.

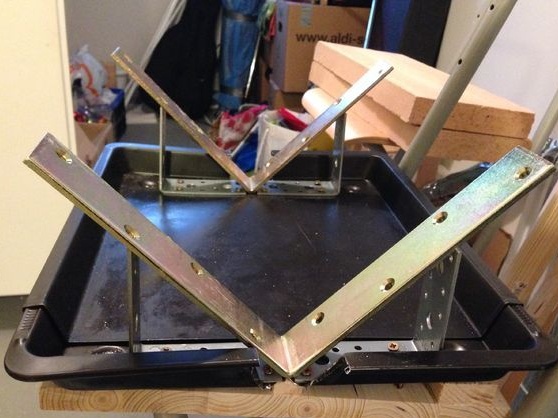

Step Four Making a frame for installing refractory bricks

To make such a design, the author used two large brackets and brackets. This whole thing is fastened with the help of large self-tapping screws. The angle of the staples is 90about.

Step Five Forge assembly

The author bought a refractory brick; it withstands temperatures up to 1200aboutFROM.However, for such purposes, you can use other materials. It is important not to use concrete, as it can explode with strong heating, which is very dangerous. It is best to purchase a pair of good bricks, because this is the most important part of homemade work.

Step Six We connect boost

To blow air, the author used a regular old hair dryer. In his opinion, there is enough power here. To connect the forge and hair dryer, a long pipe will be needed so that the hair dryer does not overheat from the stove, for this purpose a pipe from a vacuum cleaner is well suited. During the operation of the forge, the pipe does not heat up, as it is cooled by the air coming from the hair dryer.

Seventh step. Launch and testing

That’s all, the forge is ready for testing. You need to run it on the street, and charcoal can be used as fuel. According to the author, it gives out enough heat for forging, he even made a simple knife, heating the metal to yellow.

That's all, the forge is completely ready and has proved its effectiveness. With it, you can easily turn the rod into a knife. And when the forge is not needed, the bricks can be pulled out and the chair folded. As a result, it takes up little space.