Hello! Each master will soon need to cut some part that will be difficult to cut with a jigsaw. Either it will be difficult to fix, or the cut will be uneven. Therefore, you can make a jigsaw machine, which will allow you to cut small twisty parts, at an even angle. Such a machine is not difficult to manufacture, and it does not require a lot of material.

Necessary materials:

- electric jigsaw

- 3 bearings

- bolts, washers, nuts

- wooden blocks

- plywood

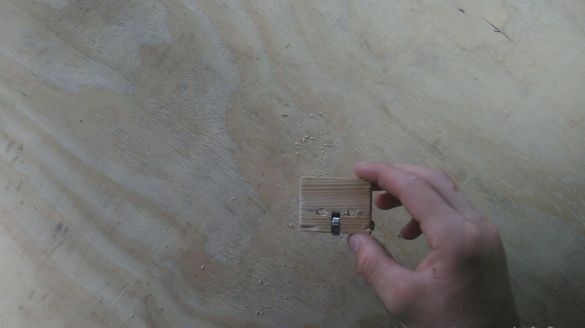

Step 1: First of all, cut a small block, and cut out a groove in it so that the bearing can rotate freely. Then we drill a through hole to fix the bearing. And with the help of a long bolt we fix the bearing so that it protrudes from 3-4 mm on one side. Next, we drill 2 holes so that each has a backlash of 5-7 mm, as shown in the photo. We take a bolt, insert it into the bearing, then a washer and insert it into the hole that we did before, and fix it with a nut. Similarly, we make another bearing.

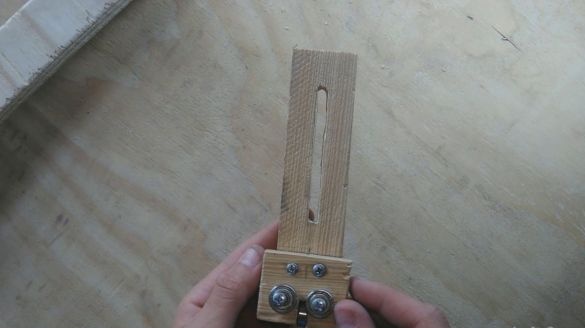

Step 2: Next, in another small block we make an internal cut 10-15 cm long. Then we fasten to it the part that we did in the first step.

Step 3: Next, we cut out a l-shaped part from plywood. And we fasten a small bar to it. Further In this bar we make recessed nuts. With the help of bolts and nuts, we fix the part that we did in the second step.

(Now you can change the height of the file from the jigsaw).

Step 4: I needed such a machine to be non-stationary. For this, I made here such a holder.

And now our homemade jigsaw machine is ready!

Testing and manufacturing: