Vacuum chamber is a useful device in the arsenal of the master. Using a vacuum chamber, you can, for example, remove air when casting parts or deeply impregnate wooden products with coloring or protective substances. With the help of the camera you can even marinate kebab. It is such a device that the Master decided to make himself. For the vacuum chamber he needed the following

Tools and materials:

- Revision Ø 110 mm -1 pc;

Coupling Ø 110 mm -1 pc;

- Plugs Ø 110 mm - 2 pcs;

- Ball valve 1/2 inch with internal and external thread - 1 pc;

- 1/2 ball ball valve with internal thread - 1 pc;

- Check valve;

- The union with an adapter under a hose - 2 pieces;

- The union under the manometer;

-Nuts - 6 pcs;

-Rubber gaskets - 6 pcs;

-Brass brass - 1 pc;

-Fixing flange 1 pc;

-Manometer;

-Manual car pump;

- Clamp-2 pcs;

-Profile;

-USHM;

-Welding machine;

-FUM tape;

- Sealant;

-Calipers;

-File;

-Drill;

-Drill;

- Hacksaw for metal;

-Vise;

-Spanners;

-Crosshead screwdriver;

-Flat screwdriver;

-Pliers;

-Litol;

Step One: Shutoff Valves

The master placed shutoff valves on the revision cover. Unscrews the cover. Files the edges of the nut skirt with a file. The plane of the nut should be firmly pressed against the plane of the cover.

Attaches nuts on the inside. Does the markup. Drills holes in the cover.

Then cuts off part of the drive with a thread.

Collects the first crane. Screws a fitting into the tap. On the other hand, it winds up a non-return valve, the valve arrow is facing outward. A barrel with a nut and gasket is screwed into the valve. The second valve also collects with the exception of the check valve. During assembly, the author sealed threaded connections with FUM tape and sealant.

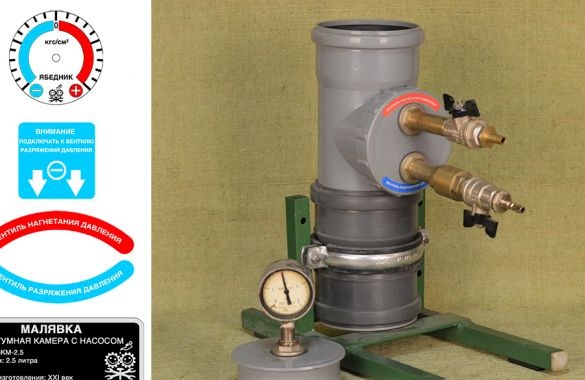

Installs fittings on the cover. Screws the lid into place. She puts on a sleeve for revision. Bottom of the coupling installs a cover on the sealant. The top cover installed on the audit, put without sealant.

Step two: manovacuum meter

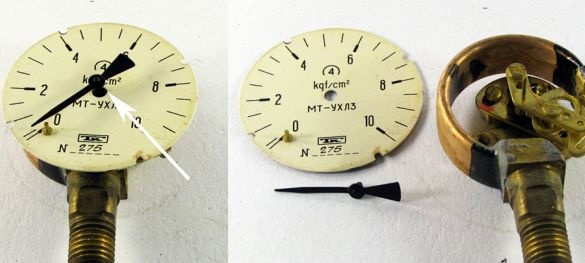

A manovacuum meter is a device that measures not only pressure, but also vacuum.Since the price of such a device is high, the master decided to make it on his own. The author used a low-pressure gauge of a gas-welding reducer as a source.

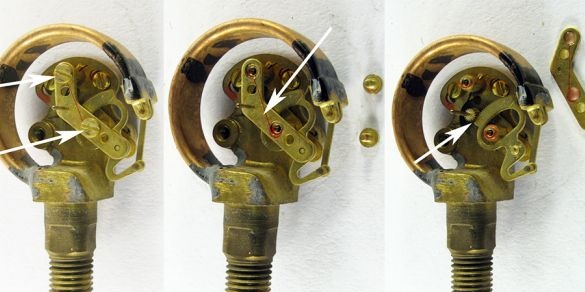

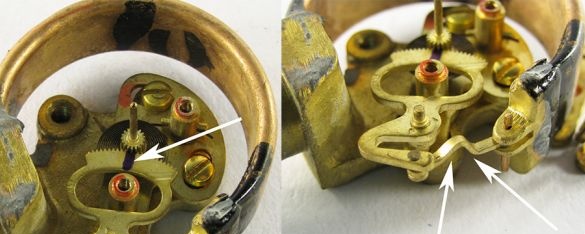

Parses the pressure gauge.

At pressure, the gear, through the lever, rotates the gear with the arrow. Since the bar is initially in the extreme position, then when discharged, it simply has nowhere to move. In order for the device to show in both directions, it is necessary to make the initial position in the middle of the bar.

Rearranges the bar in the middle position. In order for the bar to become, the author had to bend the lever.

Collects a manovacuum meter. In the original version, sticks numbers according to the operation of the device. Subsequently, the master installed a new scale on the device.

Installs the device on the top cover. Of course, the device is not accurate, but the main thing is that it shows whether there is a vacuum in the chamber.

Step Three: Vacuum Pump

To create a vacuum in the chamber, you need to pump air out of it. For these purposes, the author redid a manual automobile pump.

Parses the pump. Removes the hose, unscrews the fitting. Take out the stem.

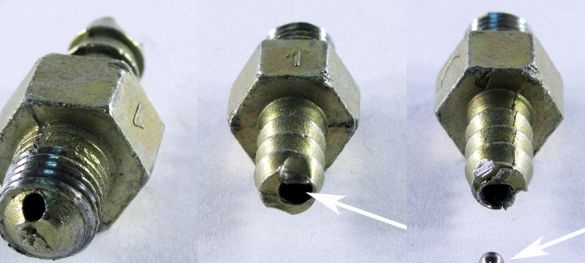

Drills a hole in the fitting and removes the ball from it.

Screws the fitting into place. He puts a hose on him, fixes it with a clamp.

Next, you need to redo the piston.

Removes the cuff from the piston. Crops the upper piston skirt. The upper and lower skirts should be of the same diameter. Turns the cuff over and puts it on the piston. Lubricates the piston with lithol and installs it on the pump. Now the pump will not pump air, but pump out.

Step Four: Stand

I welded a stand from a profile pipe. Using a flange, he mounted the camera on a stand.

Step Five: Testing and Repair

During testing, the author created a vacuum in the chamber equal to 1 on the scale of the device. During the day of testing, the arrow deviated by 1.5 divisions.

After eight years of using the unit, the only weak point was the hose.

The hose has been replaced. Information plates have also been added.

A short video about the vacuum device.