A side effect of any soldering is smoke - from various fluxes, solders, plastics - and even when it does not fly directly into your eyes, it does not add health benefits. Often we are rather careless about our health during such work - but in vain, because prolonged inhalation of fumes and smoke can lead to allergic reactions and even asthma.

It would be optimal to have an extractor that takes all the smoke out into the street, but this is not always possible. In such cases, a smoke trap comes to the rescue - it draws in and filters air from the work area, slightly reducing the content of harmful microparticles.

Serial samples of smoke traps available on the market are notable for their high price and high noise level (which distracts them from delicate work), and they also need to be kept next to the board you solder. But in fact - it's just a fan and a filter, nothing complicated. Why not make something similar yourself?

What came to my hand:

- Remains of a failed ATX power supply

- 12 volt power supply

- Filter Foam

Step 1: Device Case. Preparing the power supply.

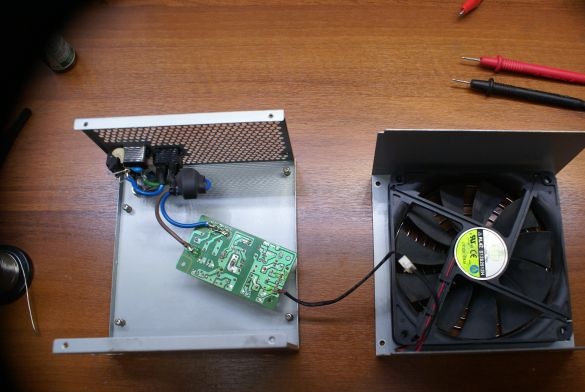

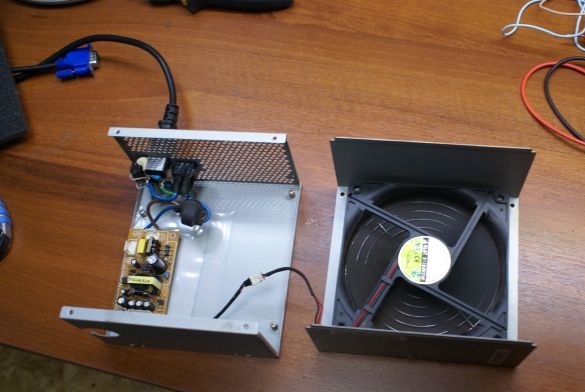

We will remove the board with the oblique wire from the case, we will remove the network wires and wires from the board to the fan. We should get a completely cultural case with a connector for the power cord, a switch and a cooler. Yes, it’s better to drop a drop of oil into the fan - so as not to worry about noise in the near future.

Step 2: Nutrition. Adaptation is available.

At my disposal was a power board from some outdated DVD player, which just produced 12 and 5 volts - 12 volts went to power the fan, and from the remaining 5 you can, say, make a beautiful backlight inside the case :-)

I soldered from the bottom of the board so as not to spoil the connectors (what if this board is needed somewhere else?), Shorted the pins responsible for starting the power supply, and soldered the fan pins. To exclude circuit short circuit on the metal case of the power supply unit itself - the lower part of the board and the case itself were insulated with a thick film.

You can wear safety glasses, a helmet, hide in cover, and try to apply power ...

There was no explosion))

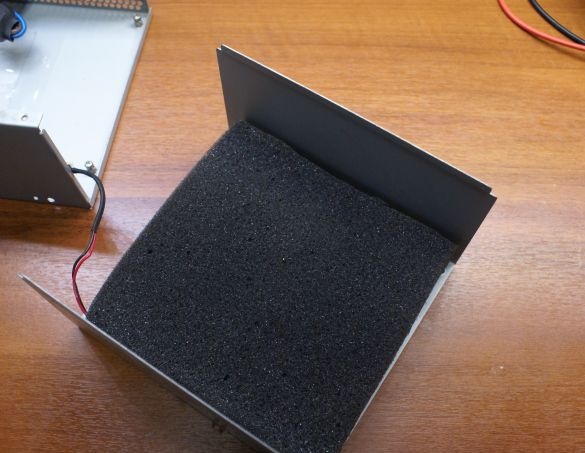

Continue - it remains to add a little filter material, and assemble the housing. I put a sheet of foam immediately after the fan, and on the grill through which air leaves the PSU, I got 2 layers of foam in the air.

We assemble the power supply housing, connect the wire, and try the smoke trap in action!

I didn’t manage to remove the stream of smoke with sufficient quality, but I can say that it goes horizontally, straight to the trap. Noise at work is not heard at all, the appearance, in my opinion, is pretty decent.

Have a nice soldering!