Making the Pizza-Box Case

(pizza box)

(pizza box)

Problem:

- We would be quick, simple, cheaper, but with taste ...

How nice and understandable is the bunch of parts working in a ball of wires and how tedious is the stage of combing and pushing it into the case.

Over time, a certain number of tricks and simple tools have accumulated to quickly achieve decent results in this case.

I think that even with access to standard world accessories and cases, the proposed solutions will be useful to many.

IN electronics typical design is accepted calmly, positively, but only. It is optimal for anonymized fruits of collective labor or compilations. But if the original idea started up in the filling, or there is another particle of the author’s self, the active principle tends to express itself externally.

How many times had to observe, by any means, bypassing the OST, GOST and customer acceptance, standing equipment acquired its true appearance!

Decision:

“Looking at the ceiling is sometimes helpful.”

I offer a simple manufacturing technology for amateur cases of a very peculiar design with great creative potential.

The basis of the design, generating the originality of its appearance aluminum I-profiles for prefabricated ceilings, so-called layouts. Such profiles were used in the USSR before the era of European-quality repair, when they were replaced by tin.

In connection with the epidemic, it’s beautiful to live, they are replaced in large quantities and are available to anyone who can prove to the construction workers that it is more convenient and profitable to give them to you than to drag them to the nearest point of purchase of stolen color goods in the dark.

Question edge.

When perceiving objects in the form of simple geometric bodies, something in our genes focuses on the proportions of the relations of volumes and projections, as well as the edges. Disharmony only in this, with all other pluses, gives a feeling of ugliness.

A compromise between volume and projection, this is pure art. For those not initiated (profanus -lat.) Into this sacrament, only one piece of advice is make everything extremely functional and no gag. It is simple and logical. Airplanes and military equipment are not made by artists, but they are naturally beautiful. But there are always questions to the military uniform designers.

In typical prefabricated structures of industrial and scientific electronics, the joints of individual elements usually form ribs. The angle that is natural for the designer is problematic for the designer. Our innate psychological emphasis on the line of intersection of faces greatly enhances the perception of natural manufacturing errors. In general, even a solidly made case, if there are allowable gaps in the corners when assembling, looks homemade.

We solve the problem of neat edges this way:

use one profile strip to get all the side walls at once. In this case, the edge is obtained by folding the profile with an arbitrary radius. As a minimum, only one connection to the sidewall is necessary and it can not be combined with the rib. The look of the case blank is very pretty.

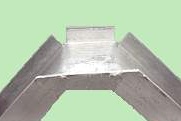

Double kink angle. Before bending the profile with pliers, the wedge-shaped sections of the visors are removed from the outer and inner sides of the future corner. In the photo of the sample, two options for sealing the visors of the angle are given.

Rounded corner. The sample shows a thinning of the T-sections in the bend area. They are narrow enough not to interfere with the fold of a given radius. Their complete removal in such a significant area will weaken the structure too much and make it “liquid”.

Easiest corner. Prior to bending, it is necessary to remove the wedge-shaped sections of the T-pieces interfering with this outside and inside. With the correct choice of the geometry of the cuts, the angle formed maintains a solid plane in its inner part.

It is possible to bend the profile without any modifications, but the rounded corner turns out to be a large radius - from 30 cm. To reduce the radius, it is necessary to thin the T-sections of the profile.

For high-quality bending in the right places in both T-sections, segments are bitten out on both sides by nippers. After this bending does not cause any difficulties. It is sufficient to connect the ends of the curved strip into a single structure at only one point. Its type does not matter, it can be riveted, screw or any other.

Several options for obtaining smooth angles with different radii of curvature are possible. As can be seen from the photographs, at large radii, the visors can not be cut off completely, which improves the appearance of the structure and raises its mechanical strength.

The sufficient external area of the side wall block makes it an excellent radiator. Normal value for calculating power dissipation: 8 cm sidewall length per watt. If there are connectors, knobs, toggle switches on the side wall, the heat sink conditions are further improved.

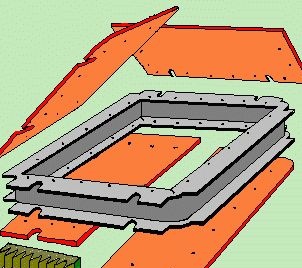

The bottom and the roof.

After receiving the side walls, you can do both the bottom and the cover. You can take almost any material: sheet metal, plastic, including transparent, foil textolite, etc. When using conductive materials, the housing becomes shielded. Also good.

In some cases, for example, for separate access to power batteries and circuit boards, it is rational to make the bottom or cover composite of several plates.

Fastenings to the side walls are conveniently screwed. It is undesirable to cut threads in relatively thin aluminum sides, it is easier to use standard nuts glued with epoxy glue from the bottom of the horizontal visors.

Experience

Working with soft, pliable material is absolutely not a burden. It can be cut with an amateur hacksaw, a slot, cut with a knife, bite complex shapes with nippers, and drill. All this quickly and directly for a specific device, even without a drawing. It usually takes me about an hour to get to the case. To buy ready-made, much more is required.

Design

A design feature of the proposed design is a pair of visors running along the entire body. They not only look fresh, but also significantly improve operation and protect the control knobs, connectors, display elements between them, especially if your device is operating in difficult conditions. For light indicators, visors that shield external lighting significantly increase the contrast of the display.

A case with one or two transparent covers is very interesting.Especially if the blocks inside are worth presenting effectively. I used this technique in my time in an amateur computer "Radio-86". Very impressive.

Formally, deliberate protrusion and reinforcement of structural parts in the visual image of a technical object is a classic sign of kitsch. Here you need to be careful and not to overdo it. A good reason for introducing transparency may be to control the display elements inside.

By placing a handle on one side of the box, we get a case-like transportable device. For convenience, fingers in the area of the handle, it is desirable to make a smooth decrease in the size of the visors.

On large surfaces of covers it is great to place voluminous instructions and instructions, even those written in capital letters. On their inner surface, diagrams and fact sheets look good. Not a constructive, but the blue dream of a bureaucrat. By the way, this is also a style.

It is possible to work in a completely original field of shaping, which has no analogues in the design of equipment. If we can just make closed sidewalls of the same height, matching in height, because they used one profile, then no one can forbid using them one inside the other. When covering them with a common lid, and fixing on it, the enclosed contour can be opened outward by making holes along its inner perimeter in the lids. A flat case with contoured internal holes - it's fresh! It remains to find such a find a well-reasoned functional purpose. If it is, success is inevitable.

What you create, or want to create, can be checked by the international classifier of the degree of protection of the case from dust, moisture and electrical safety. The letters IPnn with two digits will help to objectively compare your project with commercially available foreign counterparts.

Construction Examples

Typical enclosure for experimental equipment. For separate access to the areas where the nodes are located, the upper and lower covers are partitioned. Screw cap mounting. Usually, input, output and control connectors, fuses, etc. are placed on the back wall, and the front panel is organic for indication and operational controls. On the side walls reserved places for external radiators. From the sides it is convenient to exit the slots of the trim tabs and the pads of the setting switches. A pair of grooves on each of the side walls serves to pass vertical fixing screeds when installing our device in a rack of similar cases. Naturally, the sections of the side walls behind the grooves must be left free.

In this design, the plastic capabilities of the material made it possible to fulfill the casing of the coil of the built-in power cord in a single module with the hardware. To obtain a bend radius without curvature of the sides, the radius of curvature in the casing region of 140 mm, it was enough to reduce the height of the side protrusions by 60%. Reduced lateral protrusions in the steed of the lower part of the housing, to obtain "legs" that improve the stability of the structure when installed on the ground.

The design does not have to consist only of a profile. An experimental model of the on-board “television center”, which switched and mixed signals from several cameras, also had a case design with only a profile in the upper part. They are used in test flights to monitor the behavior of various structural elements of the airframe.

Under reliable protection of visors that do not extend beyond the outer contours of the case, there are toggle switches, axial switches, and display elements. Orthogonality of controls with a patch panel located on top provides added protection against the vicissitudes of life.In two years of active life of this model in brutal expeditionary conditions, real tests of failures due to "mechanical attacks" were avoided.

In small-sized cases, the use of an aluminum profile around the entire perimeter, due to the internal visors hanging over the board, limits access to the elements. A more convenient hybrid design using a profile only for short, end faces. The main forming element is a cover with formed sidewalls, assembled resting on the ends of the aluminum profile. Access to the details of the board with the cover removed can be considered ideal.

For example, the figure shows a programmer that is software compatible with the popular Krot-RT / MK series. At the ends there is a connector for a data cable (RS-232C), a socket for an external network power source and a connector for connecting individual chip modules.

The complex body shapes obtained from the profile are not only aesthetic, but also extremely durable. Mechanically, they are comparable to cast. Their durability is inversely proportional to size. The smaller the stronger. You need to quickly make a living "in the field" - take the profile as the basis. Only one joint is sealed. We put the covers through the sealing rubber. In order not to leak inside the screw connections, we make them on the outside of the visors. We take tight connectors and toggle switches.

The figure shows the aerodrome generator of television tests. He is on the belt - his hands are free to work. Tested by the cold of Cape Schmidt, the downpours of Arsenyev, the heat in Mary.

Areas of use

- Flat constructs called "pizza-box" have arisen for use as coasters for something.

Periodically there are companies that produce personal computers in such cases. The monitor was mounted on top. Success is modest. Here, the design idea conflicts with the standards of the PC, complicating the modernization of the filling.

Now gravitate to this construct DVD players.

- Often such a construct is chosen for modular designs, rack-mountable and used in rooms originally unsuitable for CEA. Here the main competitive advantage of the “pizza box” is the low height of the case, which provides a large number of rack positions. Such flexibility, for example, is a common requirement for medical diagnostic and therapeutic equipment.

- The flat case solution is very convenient for experimental samples, as it provides excellent access to all boards and devices at once, both from the installation side and the parts. Anyone who has ever developed new devices will immediately appreciate the merits of this approach.

Strictly speaking, up to 90% of constantly repaired and improved amateur radio creations do not leave the experimental stage - as they say, the specifics of the genre.

- Inside the "pizza-box", large single-board devices are directly requested. With the integration of elements growing, so far the fashion for them has passed, but, according to individual philosophers, the movement goes in a spiral, and according to the biblical prophet Ecclesiastes and in a circle at all. How many degrees has the new phenomenon of large circuit boards approached, God alone knows, and we, as pioneers, are always ready!

- The large surface of the top cover is a strong competitive position of this construct. It is ideal for use, say, as a remote control, where there is enough space for a mass of regulators, buttons, display elements, including LCD screen displays. In addition, it is thin and the operator is comfortable working with him, laying in front of him on the table. Compare with the keyboard in front of you.

- If you attach a carry handle to the "pizza-box", you get something that resembles a case. Agree, convenient.

- If you make small devices with a lid area of up to 100 cm2, then the case will be perceived as ordinary, without pronounced pizza.Here, the main thing is to play correctly on the presence of edges, turning this feature into an allegedly thought out move. Criticism is perceived very well.

- If you make small devices with a lid area of up to 100 cm2, then the case will be perceived as ordinary, without pronounced pizza.Here, the main thing is to play correctly on the presence of edges, turning this feature into an allegedly thought out move. Criticism is perceived very well.- If this is interesting, then in domestic aviation smart missiles of the development of the 70 ... 80s, the electronic unit usually consisted of a set of octagonal ones that fit into the fuselage contours of the so-called pancakes - individual flat blocks decorated under a pizza-box with two-way access to four half-boards located in pairs on each side. It is very convenient for modernization and maintenance.

Power Features

The height of the housing allows the use of only very low-power line transformers inside it. It is possible, as is sometimes found in flat constructions, to use not one large transformer, but several small ones.

When consuming less than 15 watts, it is more correct to take an external network transformer power supply in the plug housing, and connect its low-voltage output to the unit.

At first this solution makes your equipment professionally designed in terms of electrical safety. Everything that is critical for safety is located in the purchased power supply and you have nothing to do with it.

Secondly, it is more correct to create the whole set of voltages necessary for the device by the secondary switching power sources located in the device. They themselves and their elemental base are not a problem now.

If the device consumes more than 15 W, use flat pulse power supplies (AC / DC), both purchased ones, the type of which covers all conceivable requirements, as well as self-made ones.

In the case of using galvanic cells for power supply, a housing height of 28 ... 30 mm allows you to comfortably install elements of frame size R14 (size C - American Class. ANSI) d = 26.2 mm, L = 50 mm in it.

In most cases, they are more than enough. Alkaline (in the designation should be the word ALKALINE: alkali-English) LR14 elements in terms of capacity and unit cost of energy are preferable to cheaper standard salt elements of the following popular size R20 (size D) d = 34.2 mm, L = 61.5 mm.

Flat batteries, known to us as KBS (frame size 3LR12), with 4.5V and dimensions of 62x22x67 mm fit into the body contours with a large margin.

If the idea appears to use exotic yet solar cells in the power subsystem, then the side panels, including transparent ones, are just waiting for this.

Evg. Svishchev