To process small metal workpieces, the Master made a mini-lathe. Let's see how it works.

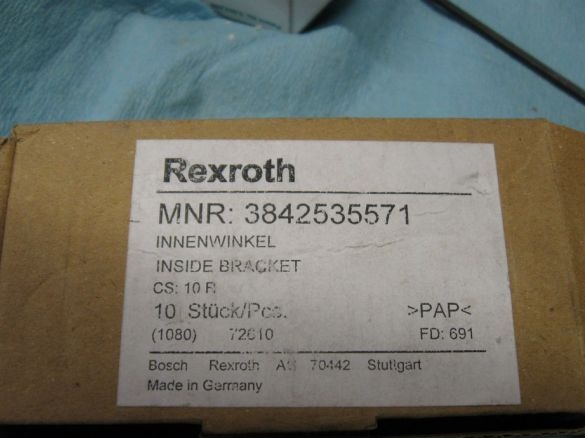

The machine works and, although there is a slight beating, it justifies itself. A plus is the adjustment of the shaft rotation speed. The master uses Bosch Rexroth parts in his machine. Unfortunately, the wizard does not provide links to details.

Tools and materials:

- Aluminum base;

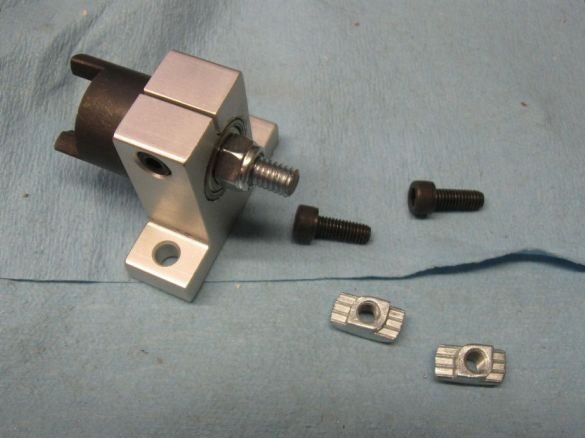

T-nuts;

-Brackets;

- End caps;

-Front and rear headstock;

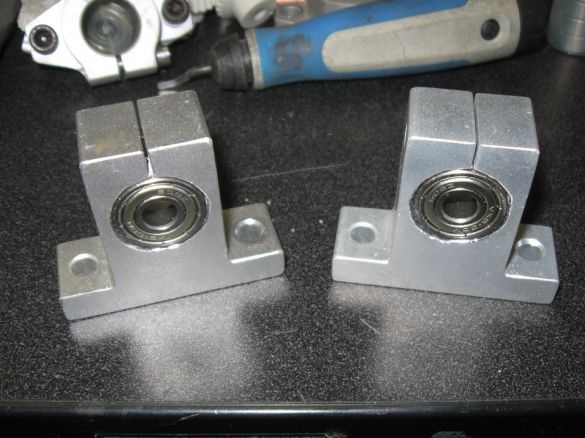

-Bearings;

-Coupling;

-12 V engine from trimmer;

Screwdriver speed controller;

-Vise;

-Drilling machine;

-Shaft for tailstock;

-Copper tube;

- hairpin;

-Nuts;

-Bolts;

-Washers;

-Hard strip;

-Welding machine;

-Paint;

- brush;

-Insulation tape;

-Wire;

-Tester;

-Battery;

-Lerka;

-Power Supply;

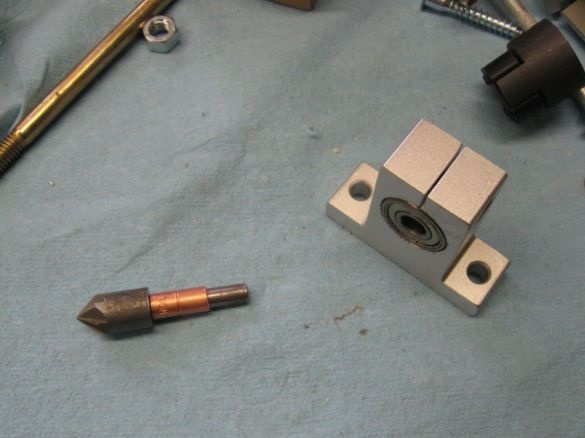

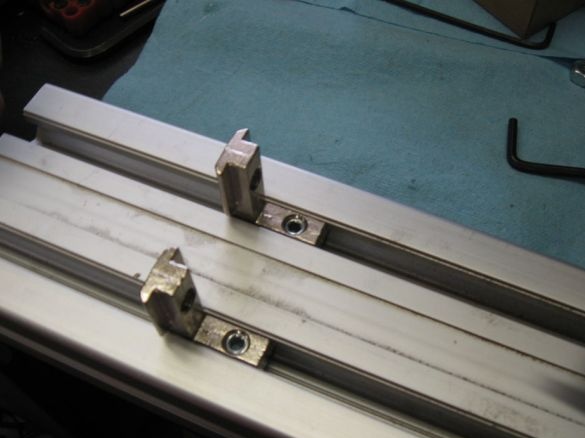

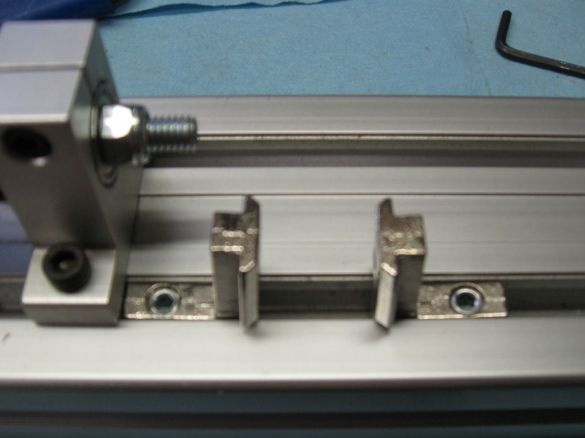

Step one: tailstock

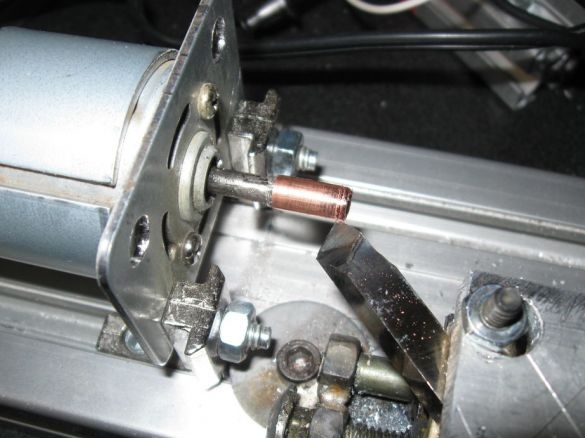

Drills holes in bearings along the diameter of the bearings. Sets bearings, tightens screw cuts. He puts a copper pipe on the quill. Installs the pinol in the inner ring of the bearing.

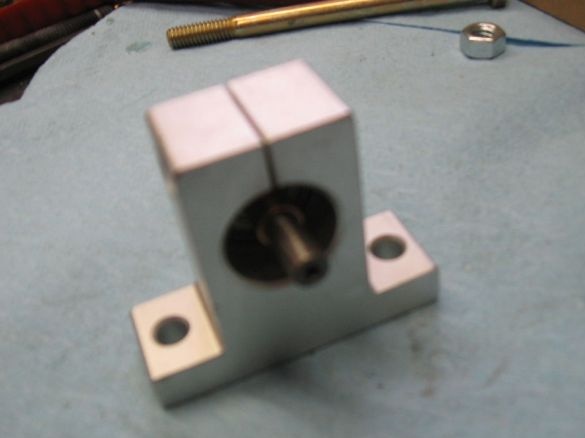

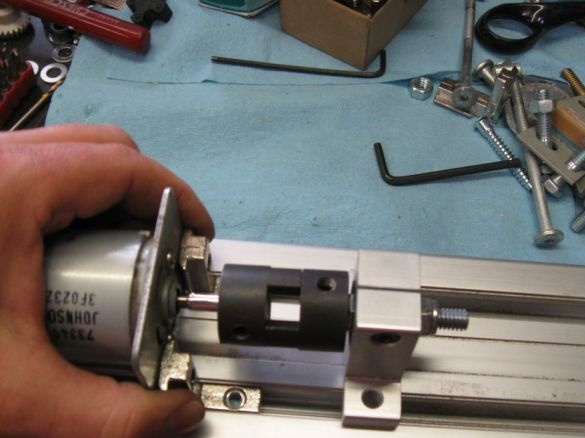

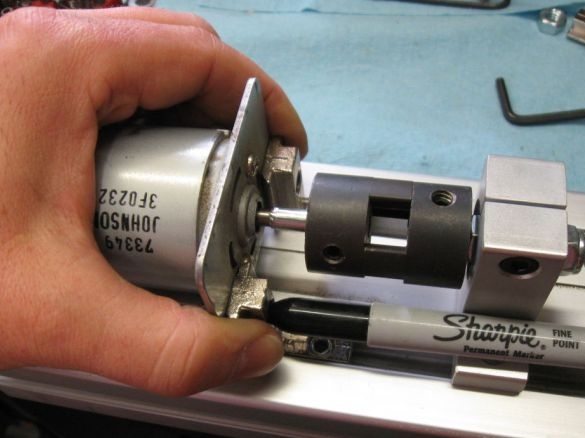

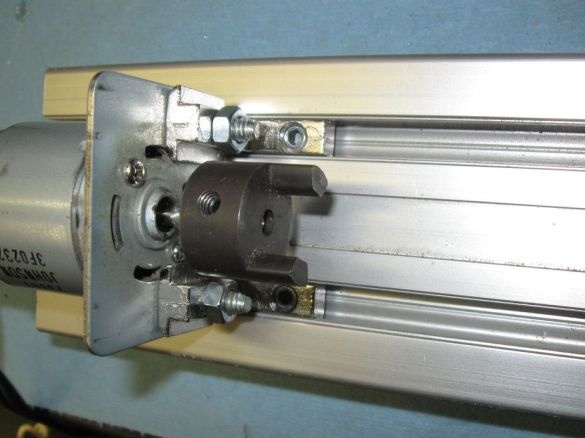

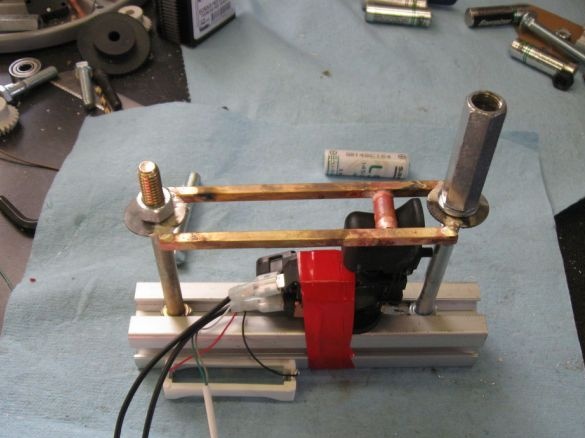

Step Two: Headstock

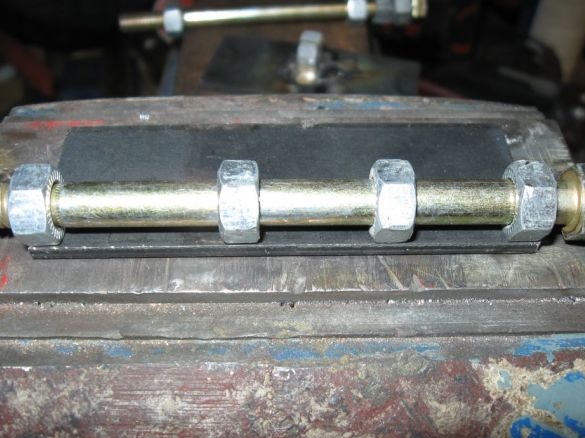

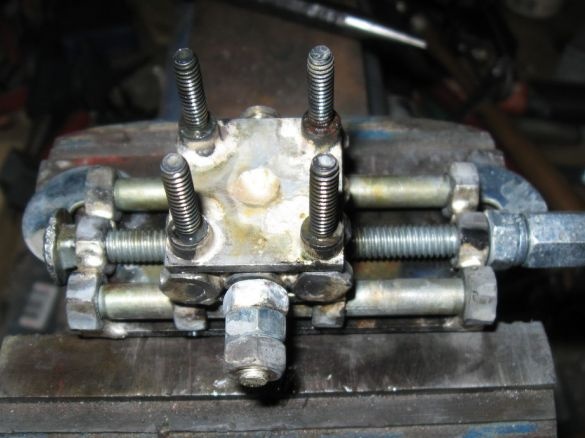

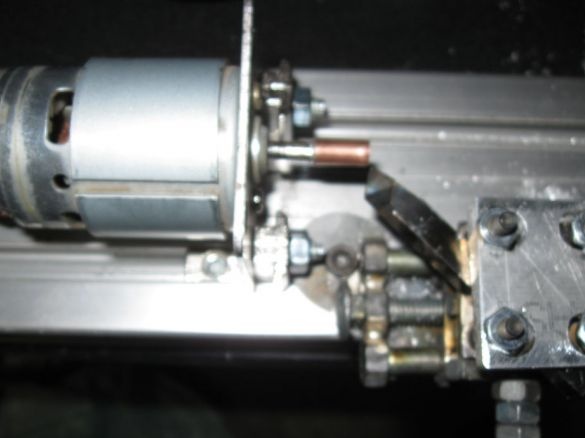

The coupling has a threaded hole. Screws the coupling part onto the stud. Tightens the locknut. Installs the stud in the bearing bore.

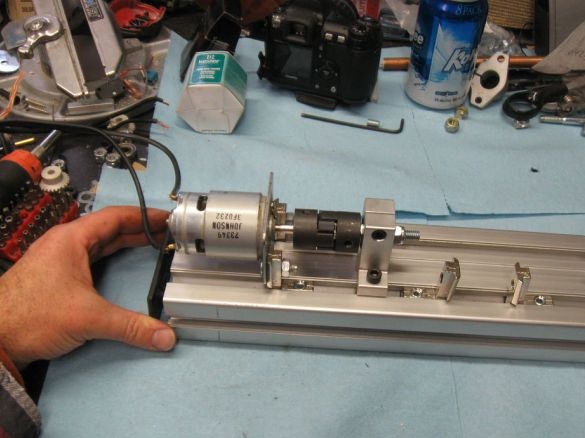

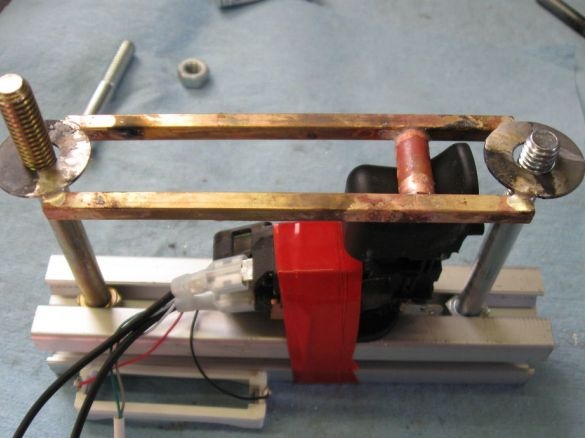

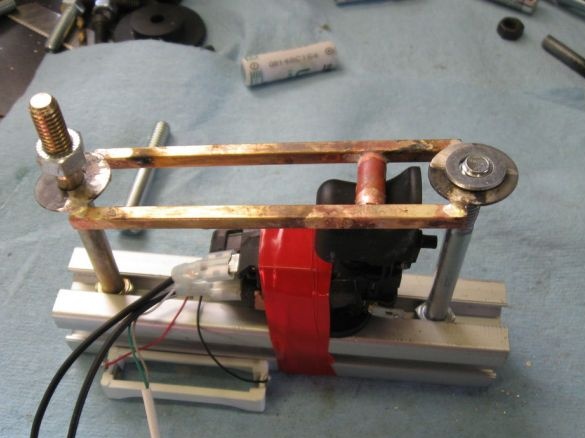

Step Three: Machine Assembly

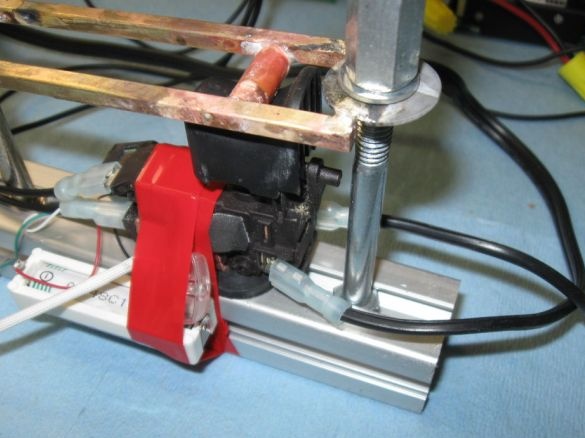

Installs the engine on the bed. A metal plate is wound on the motor shaft. Installs the second part of the coupling on the shaft. Sets the coupling cross. Installs the front and rear headstock.

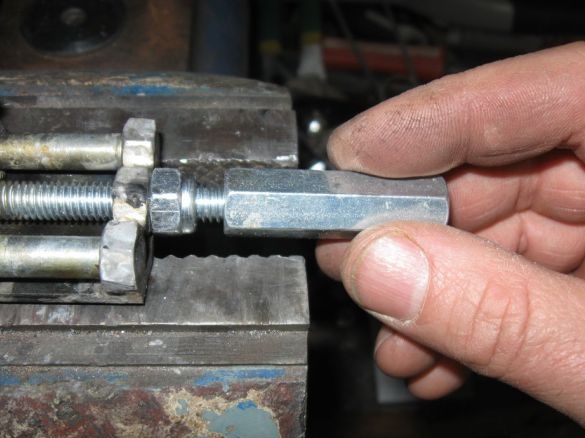

Step Four: Spindle

The master made the spindle out of nuts, washers and hexagon bolts. A nut is welded in the center of the washer. With this nut, the spindle will be attached to the headstock shaft. Three more nuts are welded around the edges. Paints the spindle. Screws hex bolts into the holder nuts.

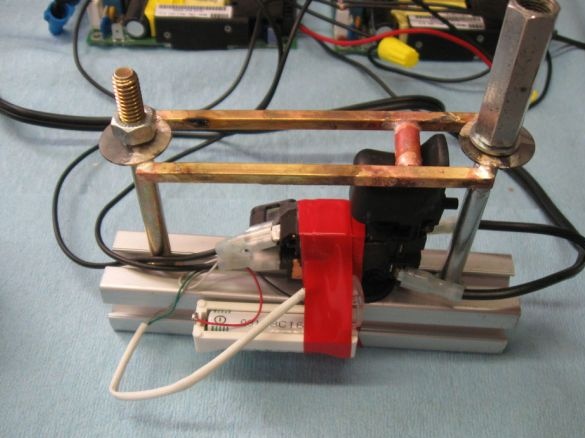

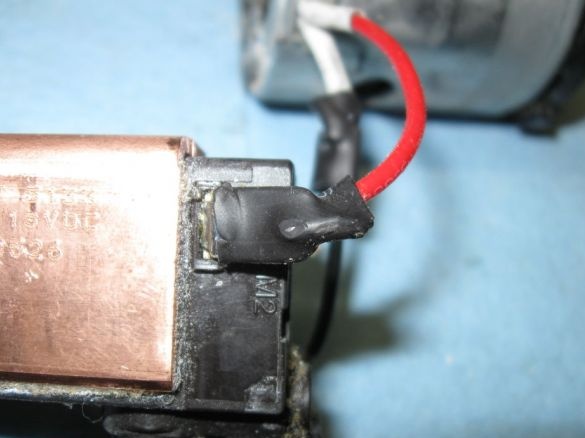

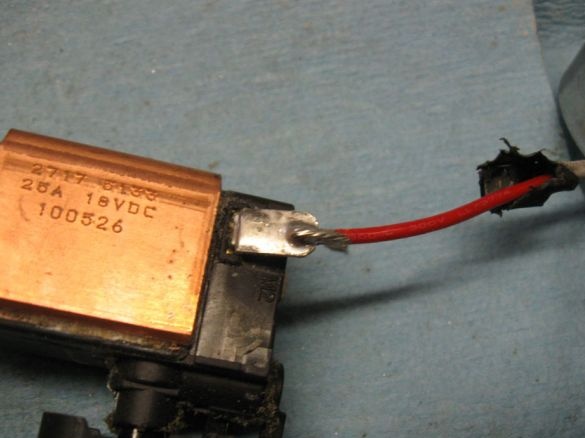

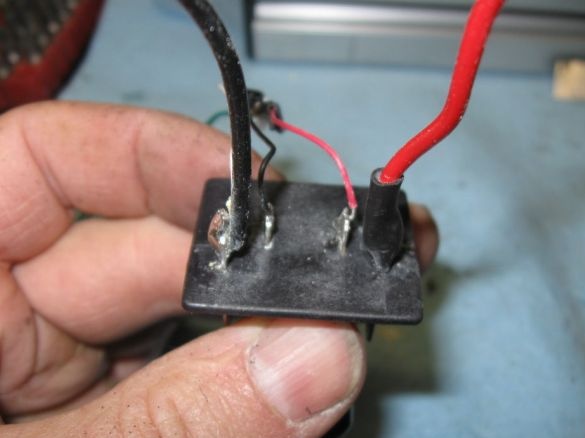

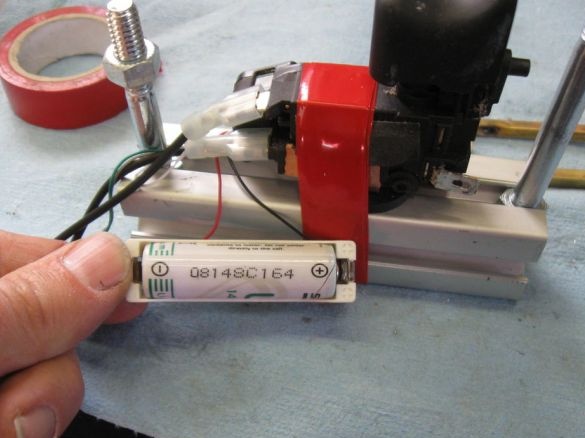

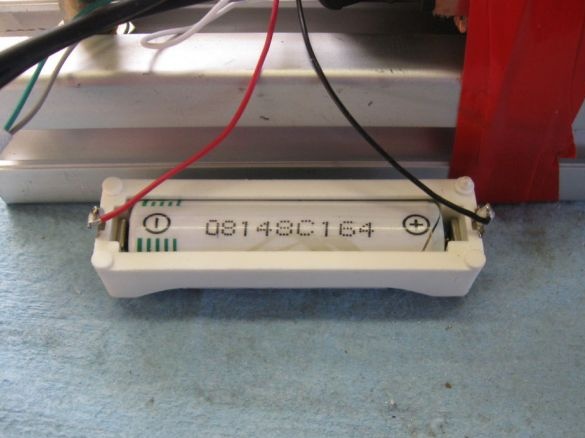

Step Five: Speed Controller

The trimmer motor rotates at high speeds, so it is necessary to adjust the speed. The master makes a device for controlling the rotation of the engine speed from the details of a screwdriver.Parses the screwdriver and removes the speed control and the power button. The button with the regulator is mounted on an aluminum profile. For the regulator to work, it is necessary to connect a 3.6 V battery to it in reverse polarity. Two studs are installed on the profile. A plate supported by a button is mounted on the top of the studs. When tightening the nut, the plate presses the button and the speed increases.

Step Six: Power Supply

For engine operation, a 12V 10A power supply is required. By connecting two power supplies, the master received the specified parameters.

Connects the power supply to the engine and checks the operation.

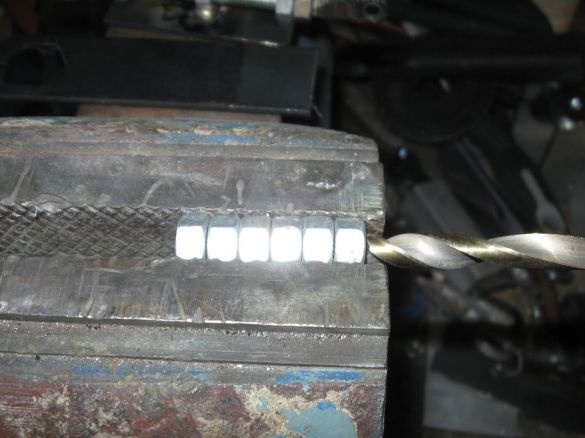

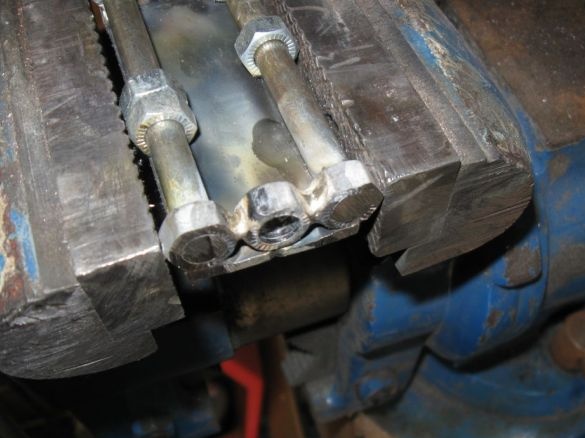

Seventh step: tool holder

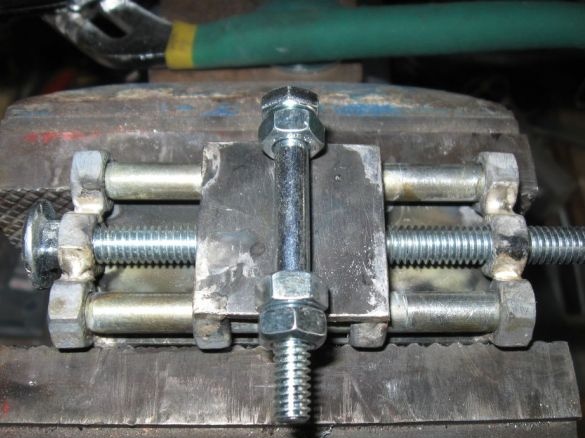

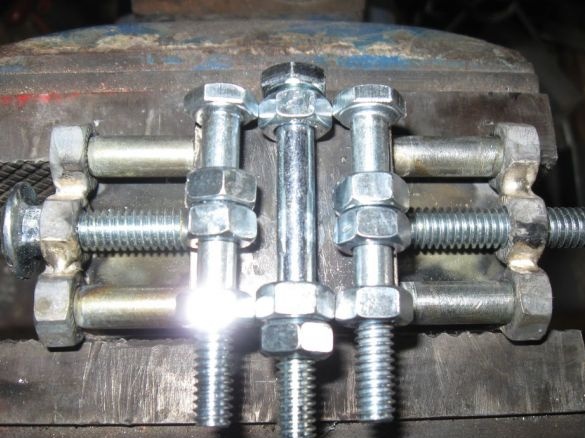

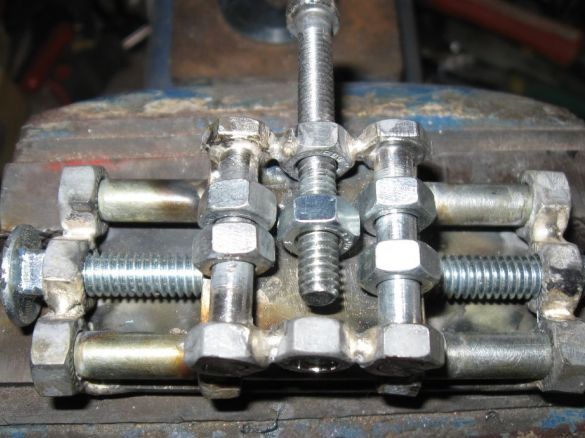

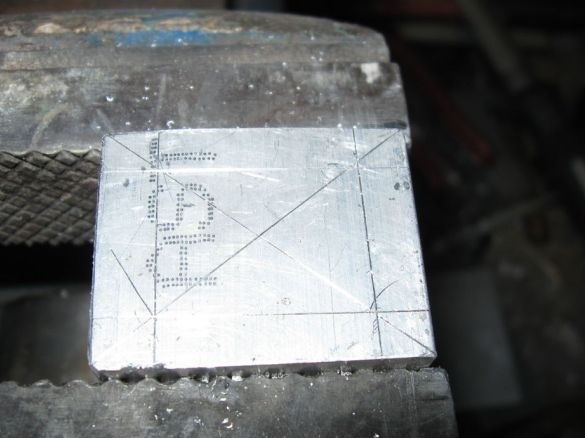

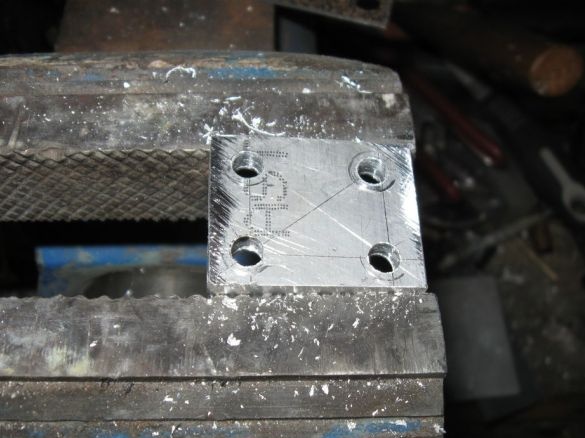

Now you need to make a tool holder.

Tightens the nuts in a vise and drills a hole. Then puts the nuts on the bolts.

Welds, as in the photo.

Adds a metal plate.

Makes sleds.

It makes a clamp from an aluminum plate.

Four washers are welded to attach the tool holder to the bed.

Paints the tool holder.

Step Eight: Improvements

Putting a plate under the engine, adjusted its height. Replaced the metal plate on the shaft with a copper sleeve.

In the future, to eliminate the runout of the shaft, the master added one more bearing to the front headstock.