In this article, we will consider the manufacture of a mini-lathe, for wood that fits in your pocket. What is such a small machine for? The fact is that the master is fond of making miniature things and, specifically, this machine, he made to grind small chess pieces. The machine has dimensions of 20.5 * 7.5 * 11.5 cm.

Tools and materials:

- Electric motor (from an inkjet printer controlling the print head);

-Bearings;

-Rear and front headstock (bearing bearings);

-Gears;

- Power supply 12V 1A;

- chipboard;

-Vise;

-Drill;

-Bolts;

-Nuts;

-Washer;

- Hacksaw for metal;

-File;

-Knife;

-Aluminum plate;

-Glue;

-Power Supply;

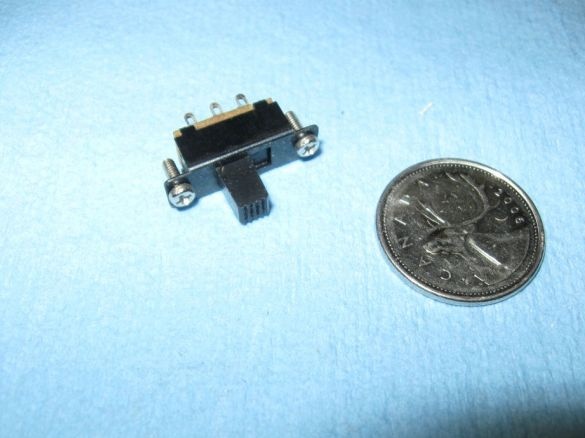

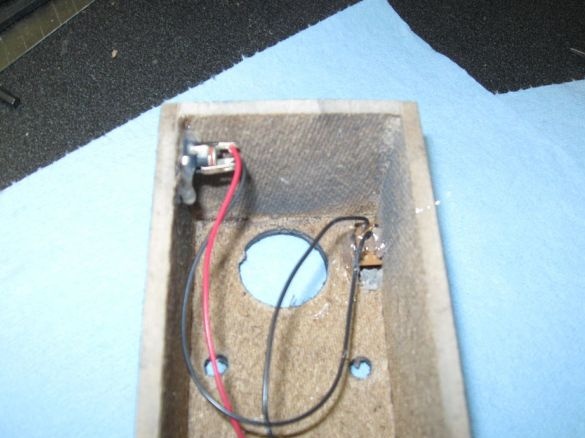

-Switch;

-Aerosol paint;

-Dermantin;

-Rule;

-Pencil;

-Sewing machine;

- Velcro;

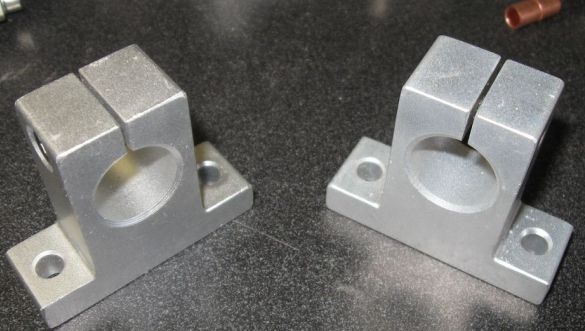

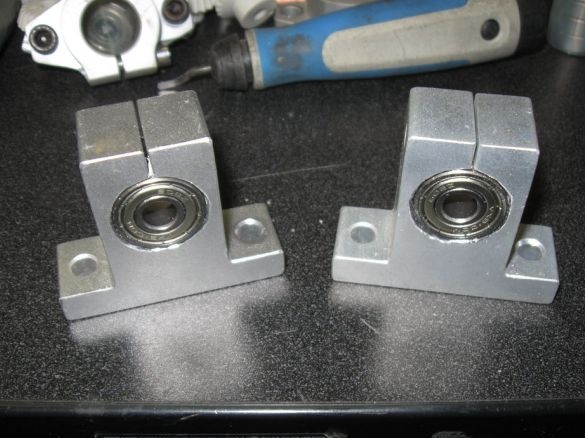

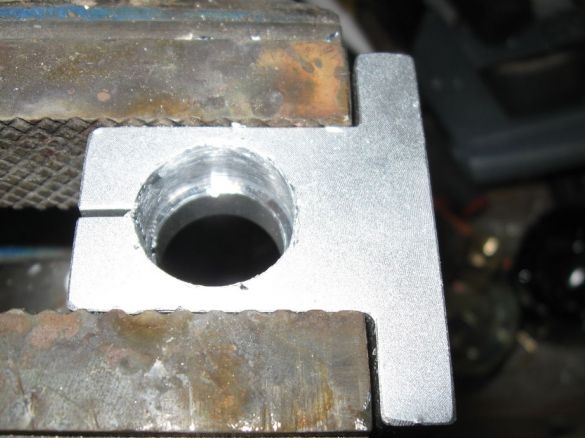

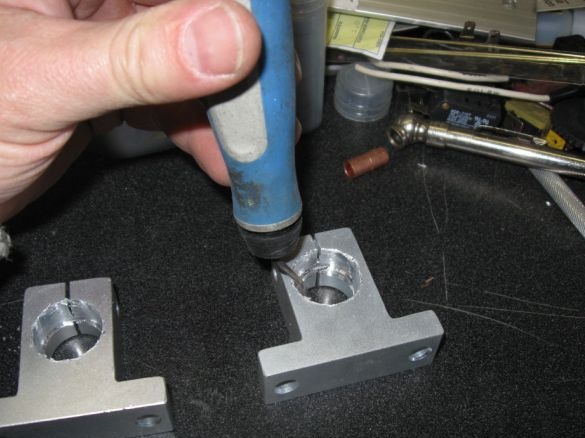

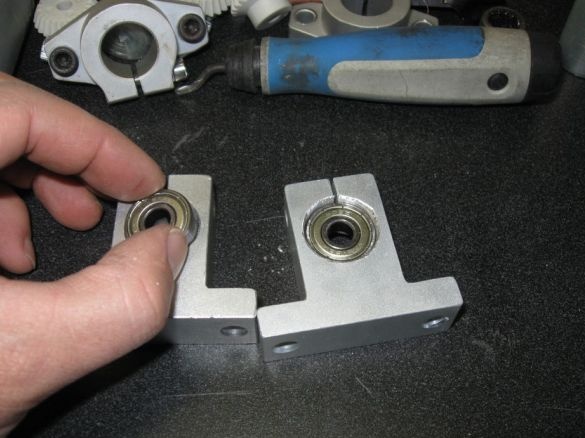

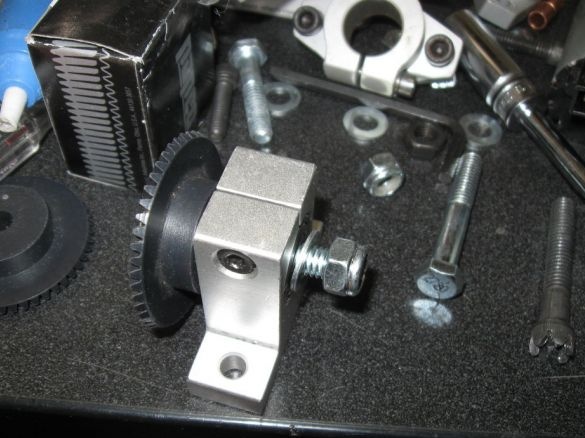

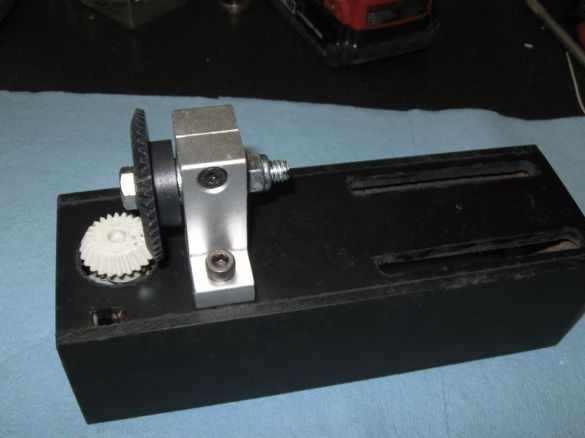

Step One: Bearing Installation

The diameter of the bearings is larger than the diameter of the hole in the bearings. Drills holes. Mounts bearings in bearings and tightens with screw.

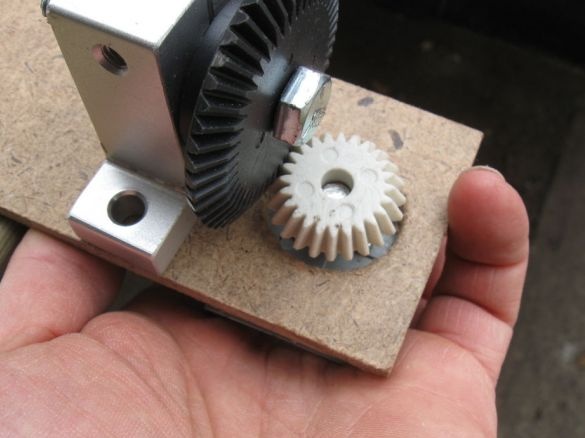

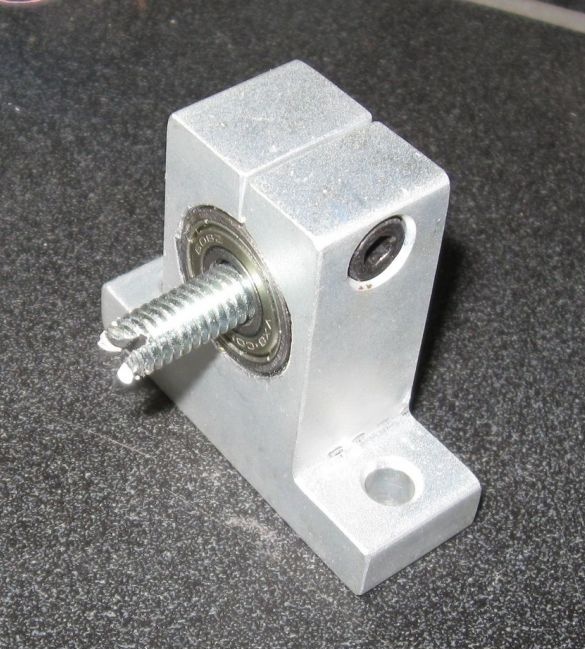

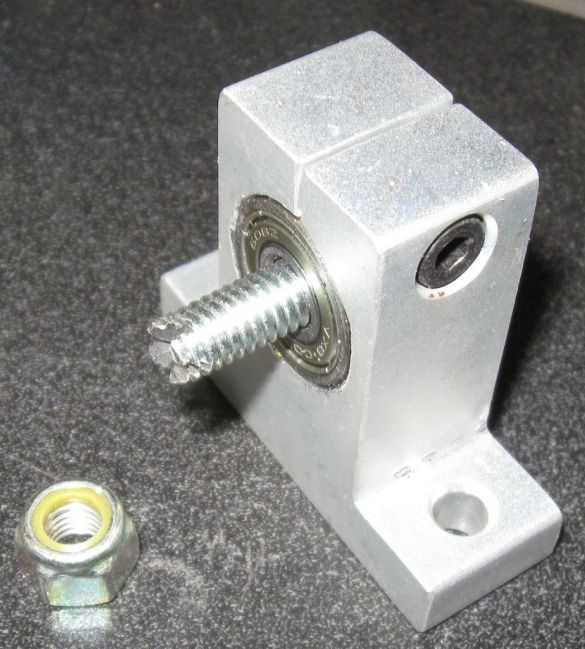

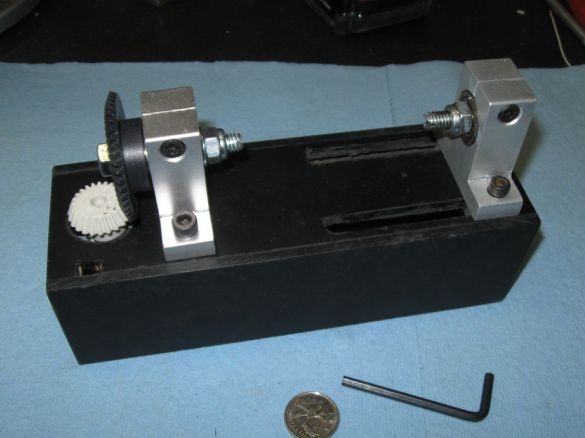

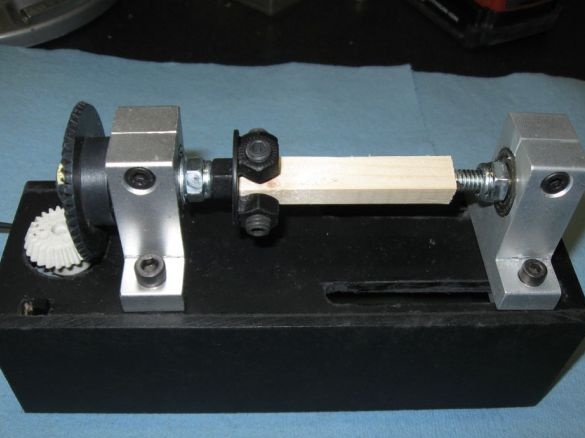

Step Two: Shaft

A bolt with gear is installed on the front headstock. For the tailstock makes pinol. Sawing the end of the bolt cross to cross. Files the middle. Installs a bolt in the tailstock.

Step Three: Spindle

Makes spindle (chuck). A nut is welded in the center of the washer. With this nut, the spindle will be attached to the headstock shaft. Next, screw two nuts onto the bolt. Welds the nuts to the washer. Similarly welds two more nuts. Paints a cartridge. Screws hex bolts inside the nuts.

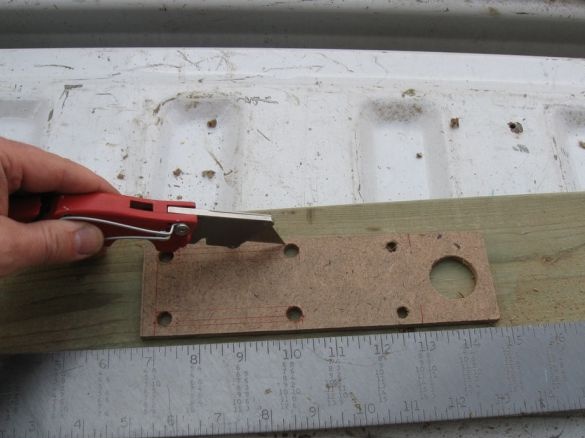

Step Four: Bed

The master made the frame from chipboard. Placed on the chipboard front and rear headstock. Made a markup. I drilled holes for mounting in the chipboard. Made a hole for the engine. Cut out slots to adjust the tailstock.

Since the engine is located below, the master glues the walls to the bed. It colors the bed.

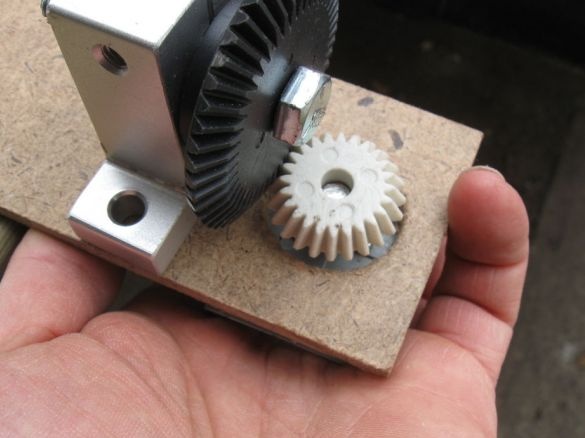

Step Five: Build

Starts to build. Under the headstock makes two aluminum plates. Raising the headstock, the master provides a pair of gears. Sets the switch. Tightens the engine.

Step Six: Machine Testing

Connects the power supply. Clamps the workpiece in the chuck and checks the operation of the machine.

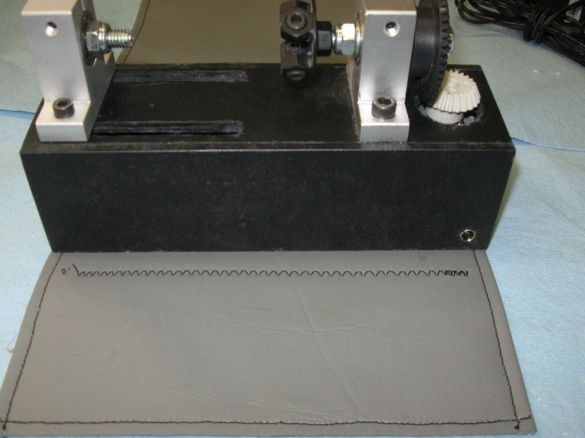

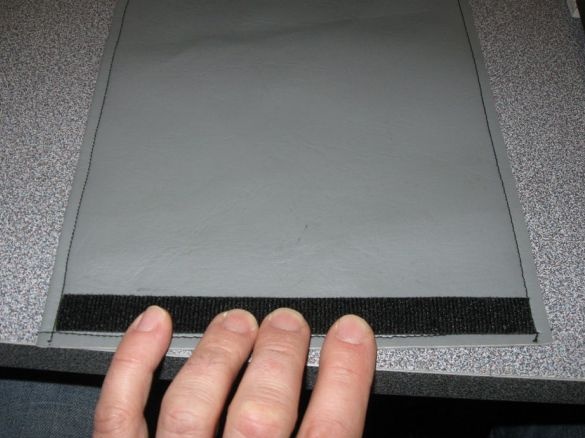

Seventh step: case

From a leatherette makes a cover for the machine tool and for cutters. The cover is attached to the bed and has a velcro fastener.

Mini woodworking machine is ready.

King and tour made using the machine are placed on a coin.