In this article, we will consider how to make a knife switch yourself. Of course, you do not need to use such a switch in a household network, but at low voltage, for some projects, as the Master does, it is. In the manufacture of the switch, the master used the following

Tools and materials:

-Copper tube;

-Board;

-Hacksaw;

- Joiner's glue;

-Sandpaper;

- Clamps;

-Tape grinding machine;

-Hammer;

-Vise;

-Drill;

-Pliers;

-Tool for flaring;

-Pencil;

-Rule;

-Screws;

-Nuts;

-Plastic rod;

-Wire;

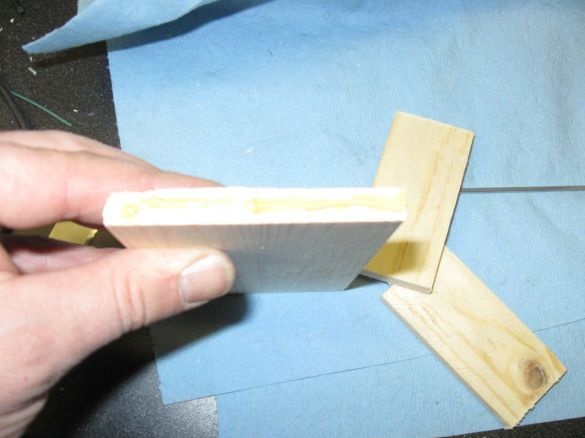

Step One: The Case

The switch case is made in the form of a box without a bottom. It makes a case out of a board. Cuts the board to fit. Grinds. Glues the box.

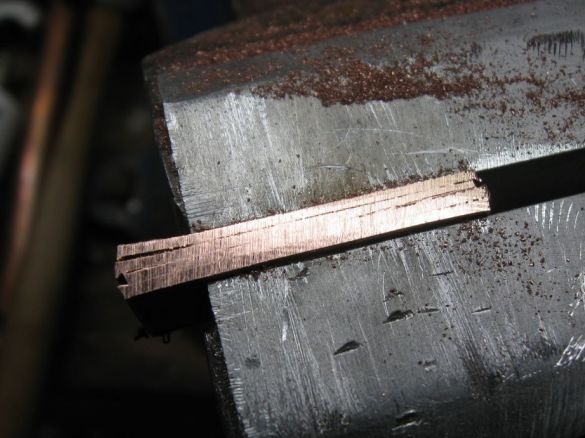

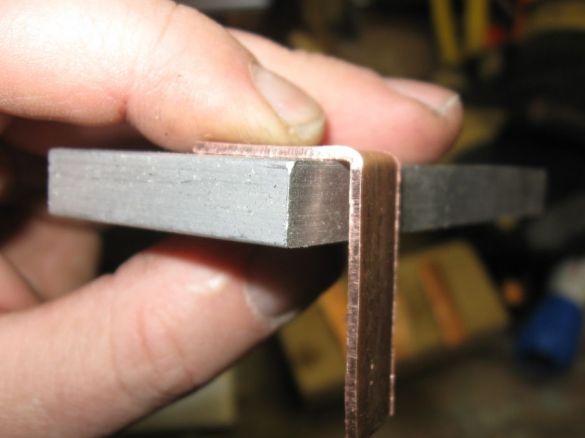

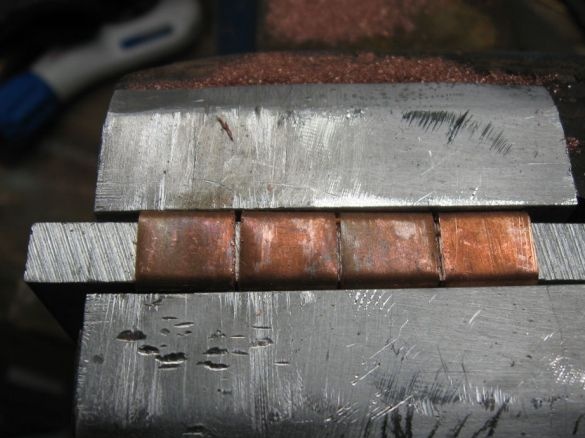

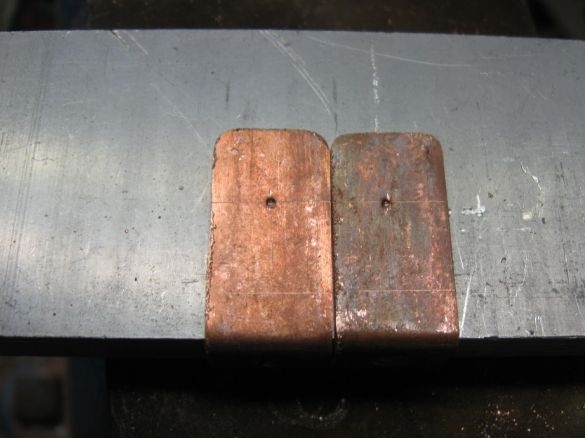

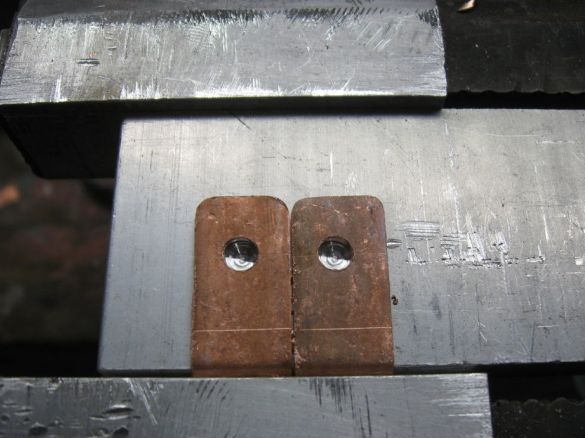

Step Two: Making Contacts

Contacts the master makes of a copper tube. Cuts off the tube. Cuts them along. Levels. The result is a copper plate. Then from the plates, using a vice, pliers and a hammer, the contacts of the desired shape are bent. Drills holes in the contacts.

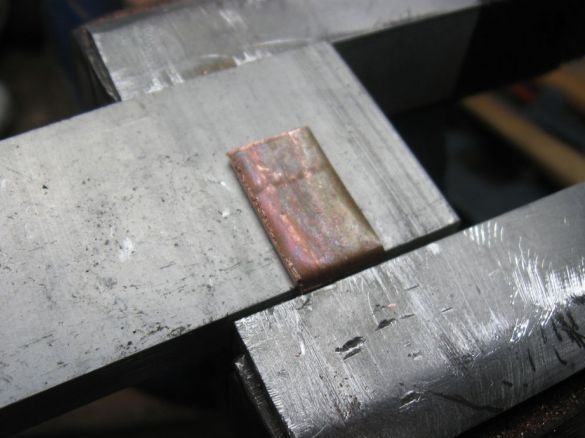

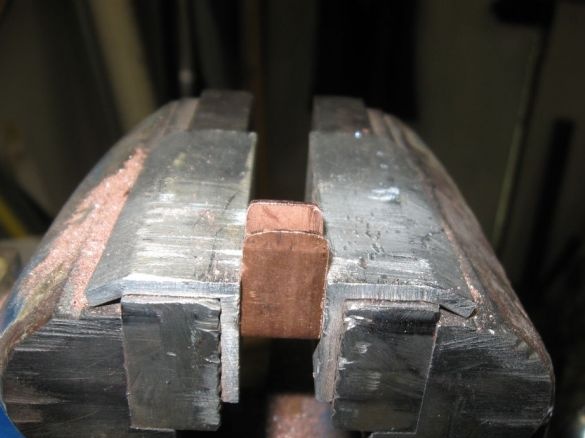

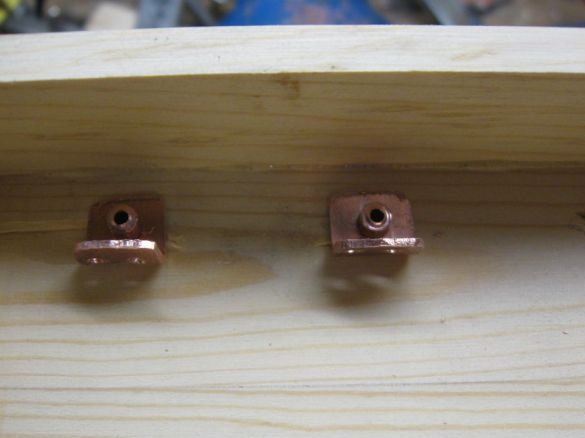

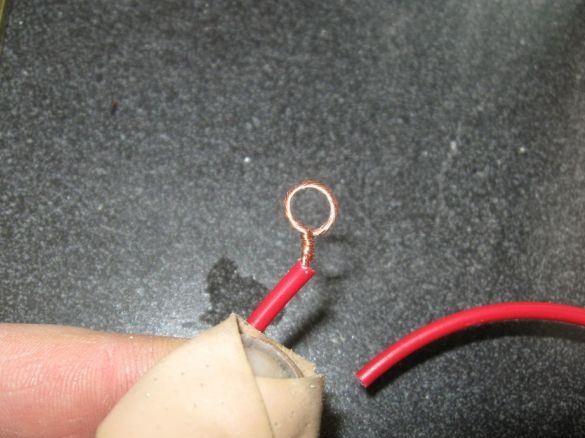

Step Three: Connecting Rivets

The contacts mounted on top connect with the bottom contacts, copper rivets made of tube.

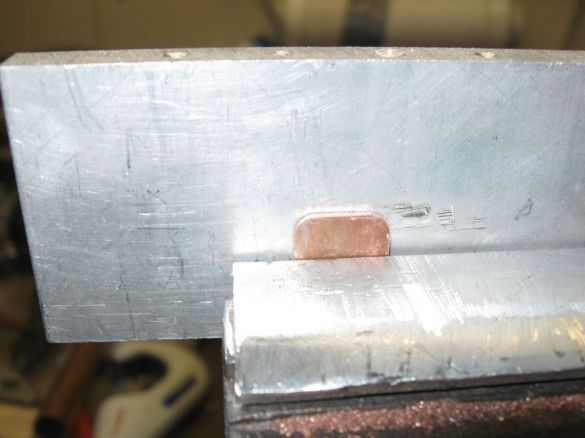

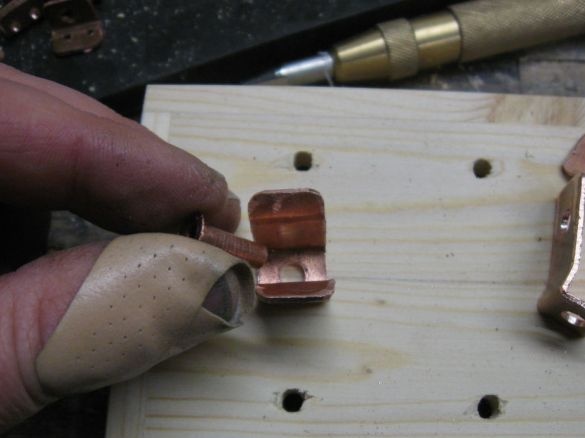

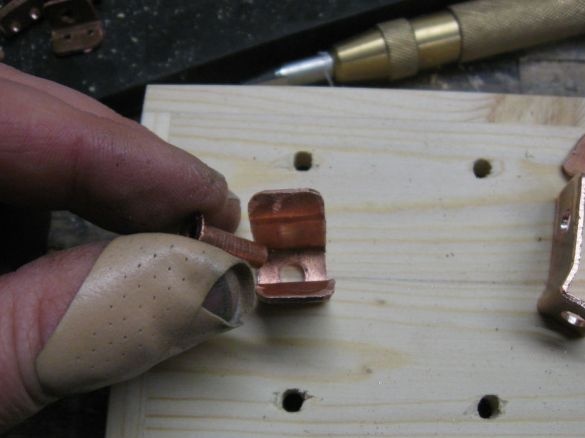

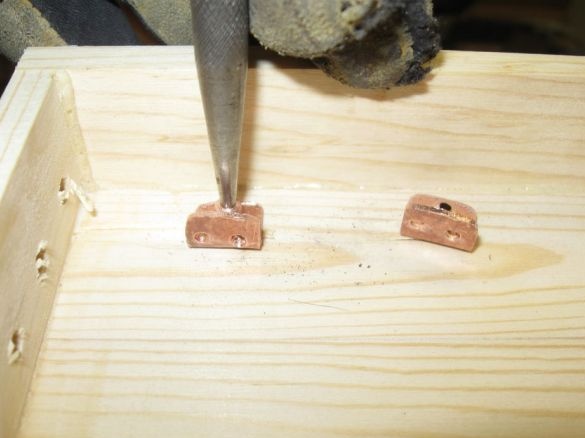

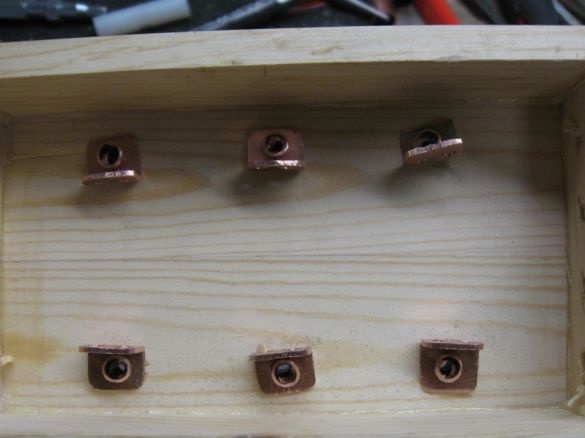

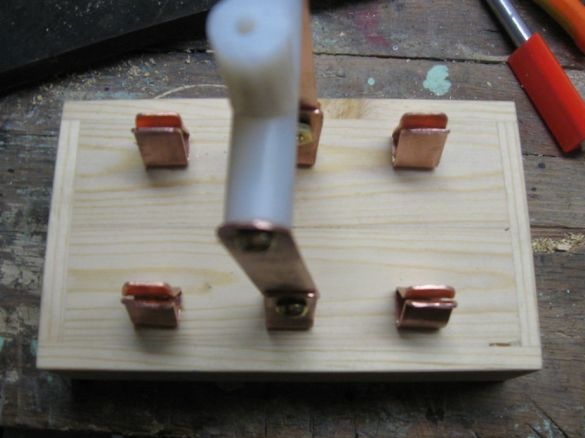

Step Four: Establishing Contacts

Marks and drills a hole in the housing.

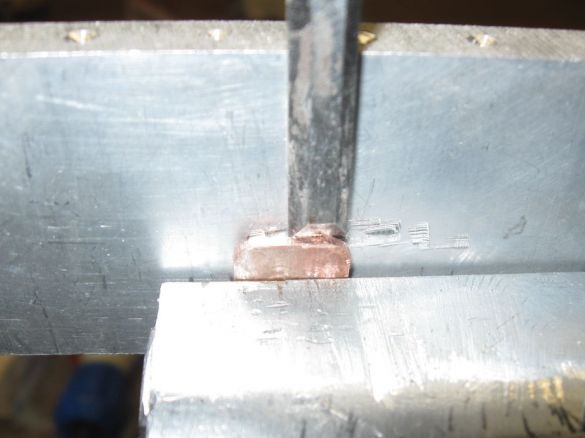

Establishes contacts. Flares rivets.

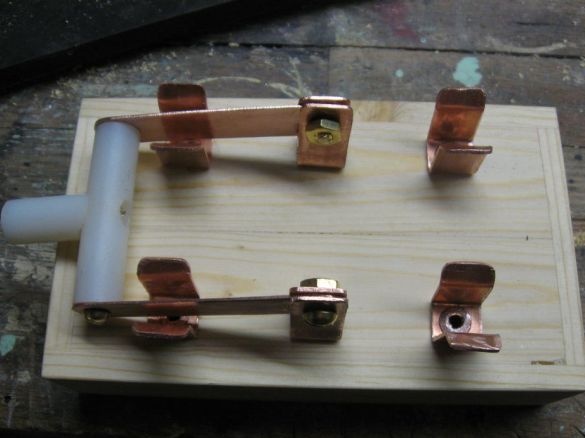

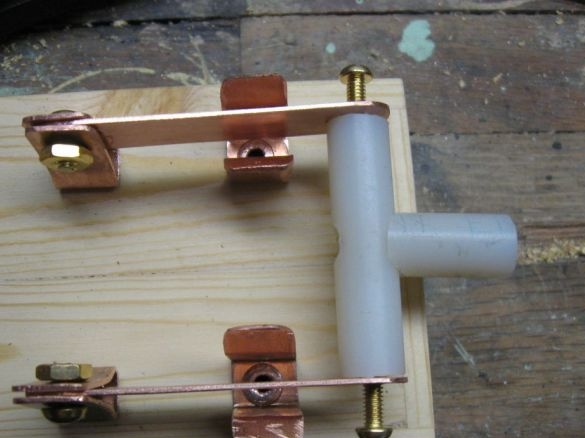

Step Five: Set Moving Contact

Installs sliding contact plates. The handle is made of a plastic rod.

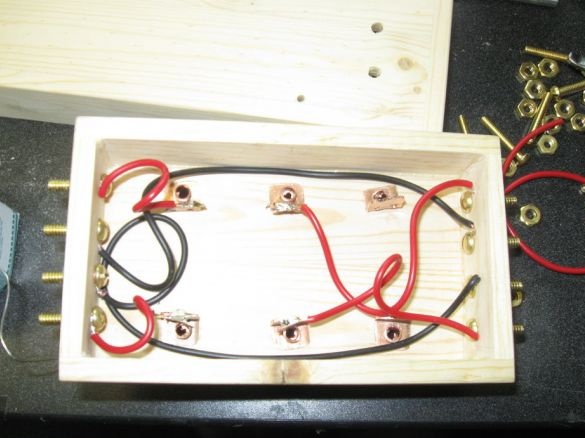

Step Six: Installation

From the end of the case sets the screws. Screws will play the role of contacts. Mounts wires inside the case.

The switch is ready.