This is a very simple version of a belt grinder, with a variable, with a stretcher, belt length.

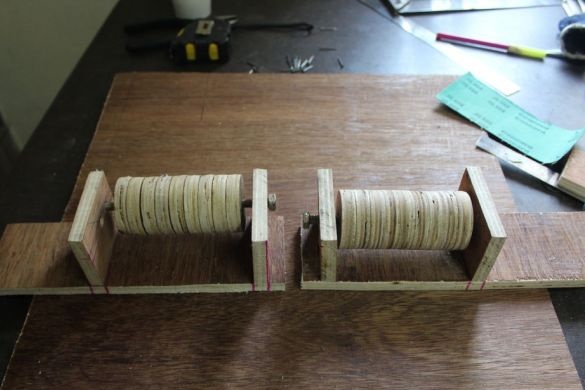

Making wooden rollers

We make two rollers to create a movable tape rotation system. The rollers are made of cut out plywood circles, which are fastened together with a stud, forming a stack of our future roller. The required number of circles depends on the thickness of the plywood and the width of the belt.

Making roller holders

The holders fix the rollers in place and withstand the gap with the lower platform, the base of the future machine. This clearance is necessary for easy movement of the belt. Since two rollers, one of which is fixed, and the other is adjustable. Holders are made of 3 pieces of plywood, where two act as sides and one as the base for fixing the walls. In the side blocks, holes are drilled parallel to each other. This is the hole through which the pin passes to secure the roller.

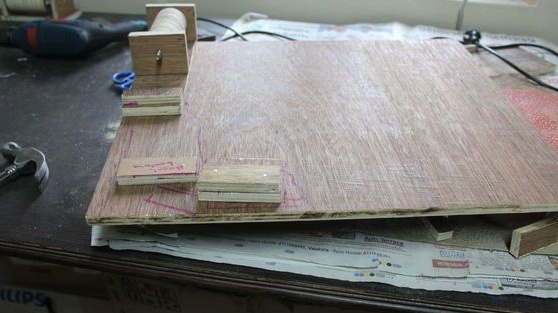

Platform Foundation

The Base Platform is the Platform on which all mechanisms are installed. The size of the platform depends on the size of the maximum length of the belt. Mounting parts shown in the photo.

Drill mount

Do not forget to fix the drill to the platform so that it does not jump ...

Belt fastening

The last thing to do is fasten the belt between the rollers. To do this, the belt must be continuous, we use resin, (Glue), and we attach the fabric to the back side of the belt (that is, not to the abrasive side), to form a solid belt. Everything is simple and affordable!