I welcome fans to craft interesting models on the radio. I present to you an interesting homemadeyou can do do it yourself. The author made a boat based. Such a motor is quite powerful, as a result, the boat can accelerate to high speeds. Of course, this is quite dangerous, because if the boat rolls over, water gets into the engine and you have to swim after it, and after that the motor will most likely need to be repaired. But the main interest is to control the internal combustion engine at a distance, and a boat based on it.

The boat itself is made quite simply, you will need ceiling tiles, polystyrene or other suitable material. Two servomotors are used to control the fuel supply system and air blades. If you are interested in homemade, consider in more detail how this boat is going.

Materials and tools used by the author:

Material List:

- ;

- air propeller;

- electronics for management;

- two servomotors;

- 3.7V battery;

- plastic ties;

- ceiling tiles;

- aluminum corner;

- wooden sticks;

- stainless wire, paint and more.

Tool List:

- stationery knife;

- glue gun;

- nippers;

- marker.

Boat manufacturing process:

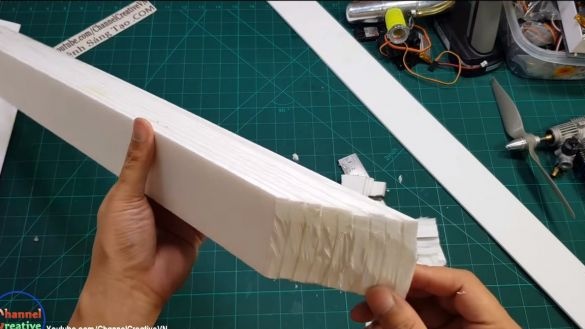

Step one. We make ski boats

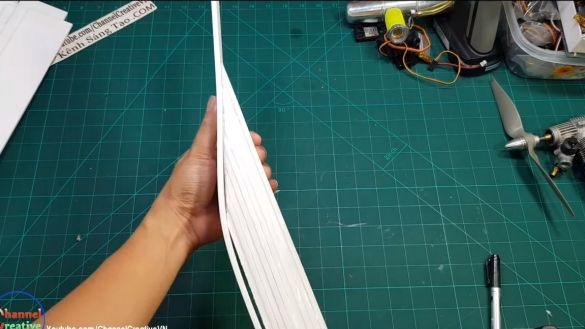

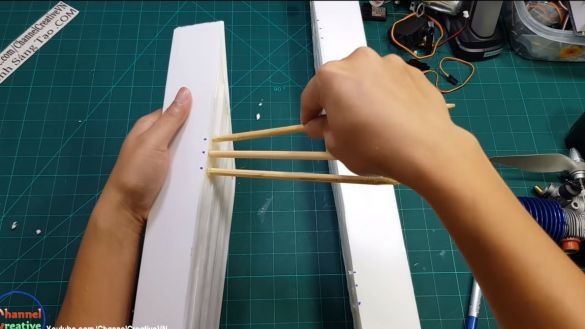

The author makes skis from ceiling tiles or other similar material. We cut the required number of blanks, and then glue them together with a glue gun. Then we glue each ski later along the contour.

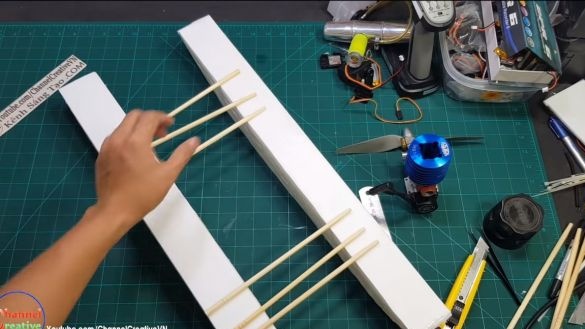

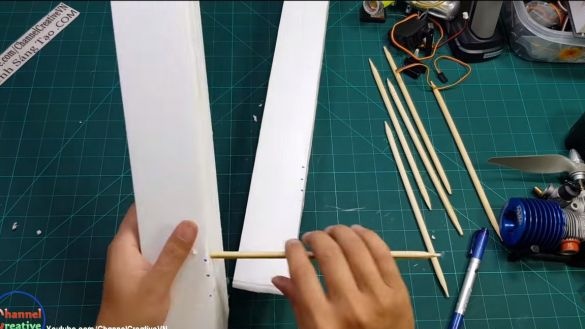

Now we need to connect these two skis. For these purposes, you will need wooden sticks, all in all, the author used six of them. We drill holes in the right places in the skis, and then we connect the two skis, fixing the sticks with hot glue. That's all, now we have got an excellent basis for installing a nitro engine.

At the end we take the spray can and thoroughly paint the entire base. This will protect it from moisture, reduce friction against water, and the boat will look prettier.

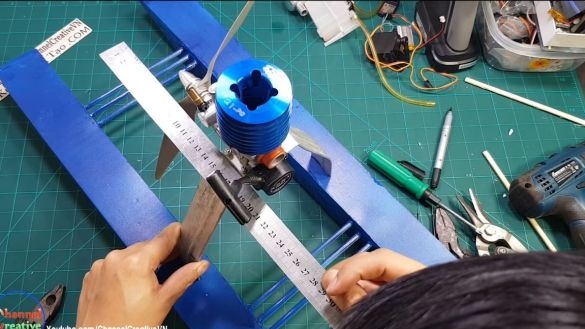

Step Two Install the engine on the base

Now you can start installing the engine. We need to fix it securely so that the motor does not come off from vibrations. For fastening, the author made two brackets of aluminum. An aluminum corner was used as the starting material, which was redone into plates. We bend two brackets and fasten them to the engine.Well, then the brackets themselves remained to be fixed on the basis. For these purposes, the author used hot glue. This is not the most reliable method of fastening, it is better to fix the engine additionally, more reliably, just in case.

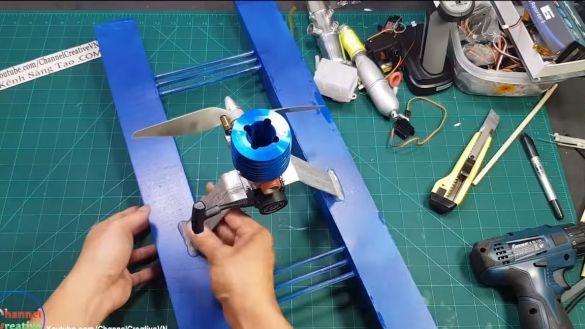

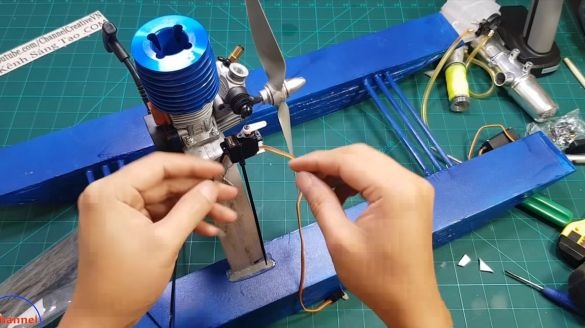

Step Three Servo motor for nitro motor control

To regulate the speed of the nitro engine, we need a servomotor of suitable power. Connect the nitro engine so that it can control the carburetor damper. To mount the servomotor, we make an aluminum bracket for it. We fasten the engine with plastic ties.

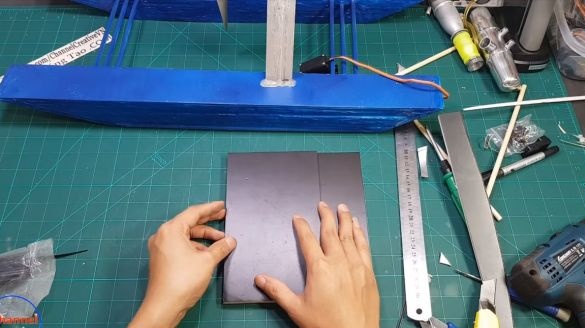

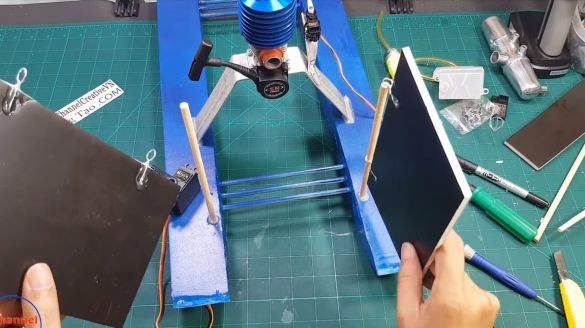

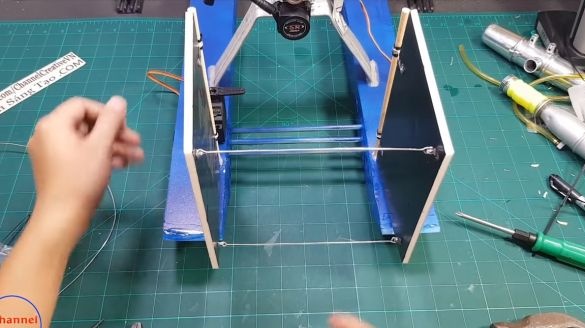

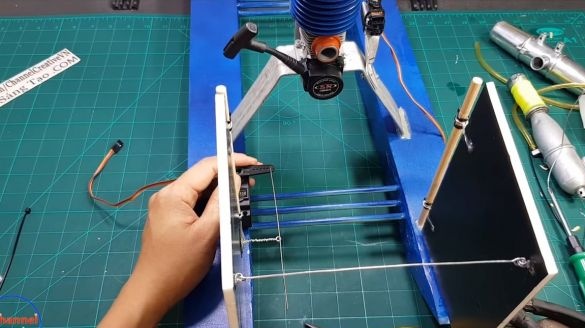

Step Four Steering

Getting to the manufacture of steering. In our case, it is airy, and consists of two synchronously rotating blades. When their angle changes, the angle of the airflow also changes and the ship turns. Such a steering wheel is good because your boat does not catch on algae and so on. For the manufacture of rudders you will need a strong, but lightweight sheet material. You can try using ceiling tiles, but you need to glue it with film to make it more durable. We take two identical sheets and drill two holes at the edges of each. We install stainless steel hinges here, thanks to these hinges we fixed the blades articulated. The blades are attached to two wooden sticks, which are fixed on the boat with a glue gun. As limiters for loops we install two plastic ties on sticks.

Half the battle is done, now we need to make both wheels move simultaneously. To do this, drill holes, screw the hinges and install a jumper between the rudders from the wire. As a result, our rudders should be parallel and rotate simultaneously. At the end, we connect the servomotor, make a loop of wire, as well as traction. At the end, we check whether the servomotor turns the rudders correctly.

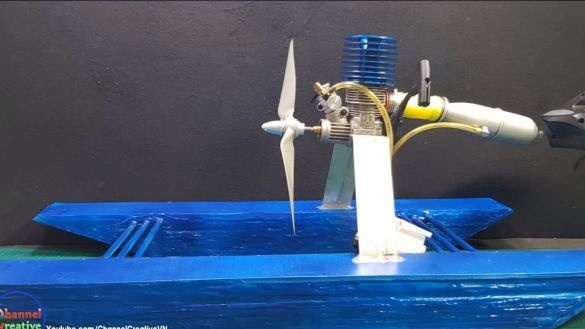

Step Five Muffler

We need to fix the silencer somehow. For these purposes, we take a stainless wire and fasten it to two drains on which the steering wheels are held.

Step Six Connect the servomotor to the carburetor

To connect the servomotor to the carburetor, we rearrange the servo lever to the desired position, and then we attach it to the carburetor lever using a stainless wire.

Seventh step. Electronics

We install a receiver on the ship’s forest and connect two of our servomotors to it. We also install and connect the battery. Its capacity should be enough to power the receiver and two servomotors. Securely fasten all parts on the case using plastic ties. At the end, you will only have to install the gas tank.

Step Eight. Testing the boat!

Pour fuel for nitro engines into the tank and proceed to launch. To start such a motor, you need a special starting battery. At the author, the engine starts with a bump. We try to see if the servomotors are working properly. If all is well, go to the pond and start. The author did everything perfectly. Remember that it is better not to use such a boat on the waves, and it is dangerous to overclock it strongly. If the boat rolls over, the electronics fails, the servomotors and the nitro motor get wet.

That's all, the project is over, I hope you liked it. Good luck and creative inspiration, if you want to repeat it. Do not forget to share your best practices and homemade products with us!