This article will be interesting to all masters working with metal, and homemade work itself would be useful to everyone.

In this article, the author of the channel "This Old Tony" will tell you about how to make another version of the clamping device, in previous articles I already wrote about such fixtures. This time it will be a cross between a stationary vice and a clamp. Apparently Tony is a great comedian, but I will try not to leave the riddles in the article, while retaining a couple of copyrighted jokes.

For the manufacture of homemade products - turning and milling work are used, so that one file is indispensable.

Instruments, used by the author.

- Turning, drilling and milling machines

- Filing machine

- Vise, clamps

- Grinding machines

- Taps right and left

- Hammer, file

- Cat metalworking

Materials

- Various steel blanks

- Round keys

Manufacturing process.

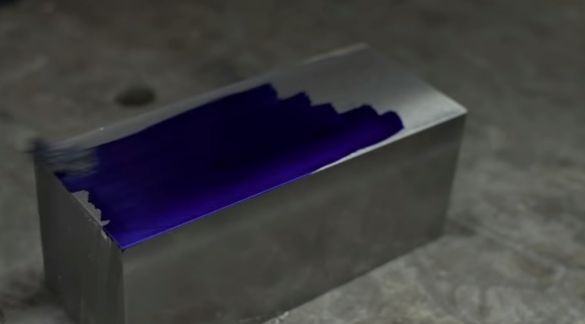

Tony begins with the processing of steel billets, this is such a bar.

Since the edges of it leave much to be desired, it pinches the milling machine in the table and processes them.

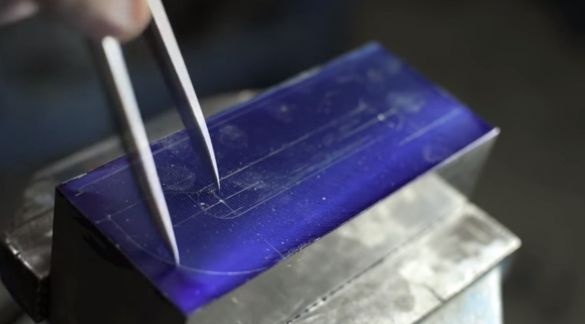

Then he paints one side of the blank for marking.

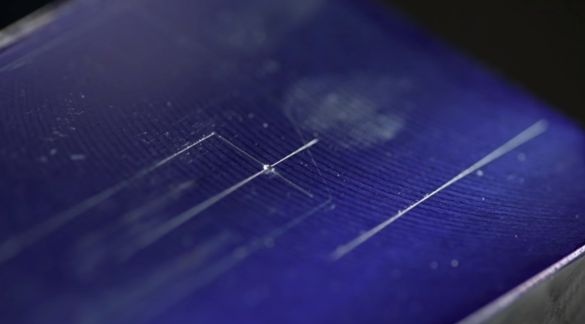

Draws lines with a marking pencil and compass. Kernit centers.

Drills two holes.

Now he hammers two wooden caps into the holes and pours them with water. After a while, the tree swells, and the workpiece bursts along the marking.

Okay. Above was an author's joke. I cut the blank on a band saw and got two such details.

Drills two holes on the machine in each workpiece.

Then cuts off the excess parts with a band saw.

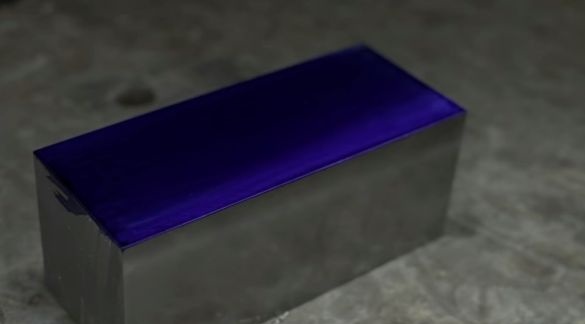

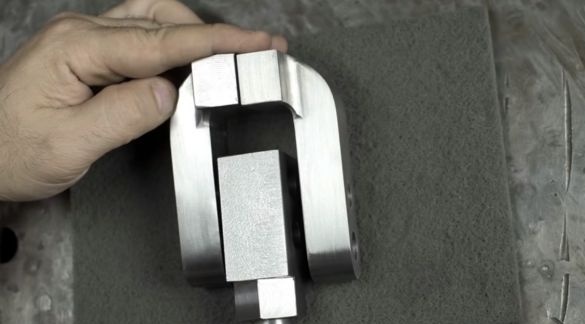

This is how the blanks look at this stage.

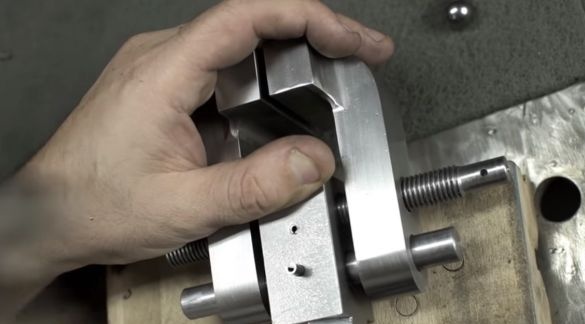

Using special clamps, it fixes them on the table of the milling machine and processes the edges.

Appearance is getting better and better.

Further, grinds internal radii using a filing machine. It seems that Tony sawdust in the form of sleeves obtained.

The next belt grinding machine.

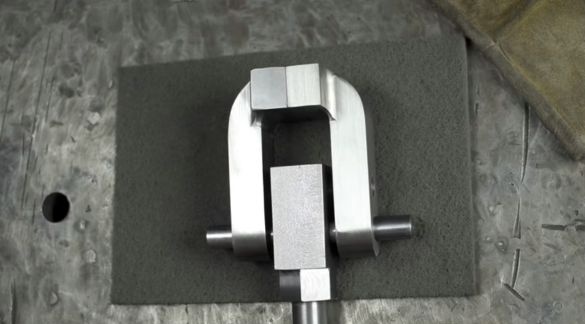

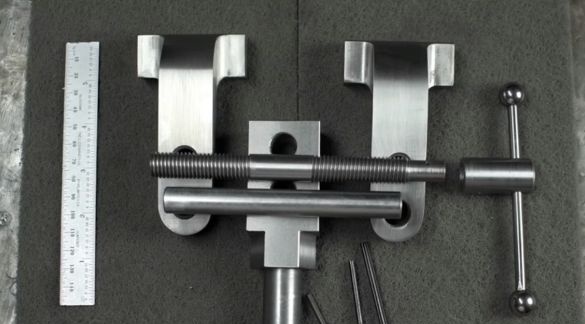

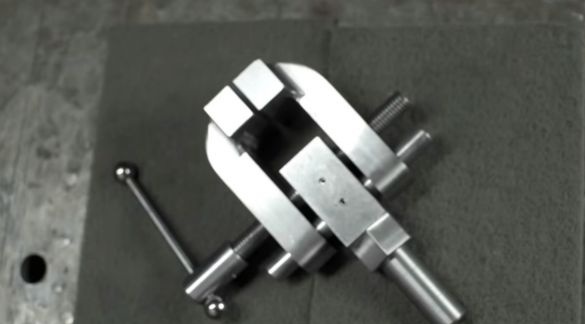

So, the moving parts in terms of aesthetics are ready.

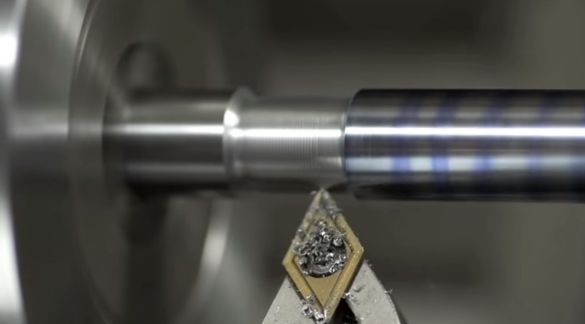

The author proceeds with the manufacture of the base. Again a small steel bar clamps in a turning and grinds one side. This will be one type of mount.

In order to fix the future clamp in a vice at different angles, another part of the base is grinded off with a mill.

The main details are ready.

To get small details, Tony will use a special cat. It's time to feed him.

After a while, all the details can be found in the tray.

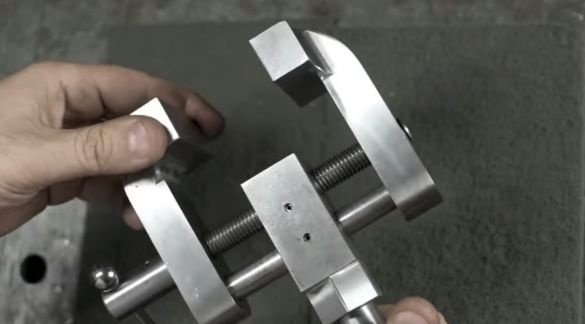

Trying on the guide.

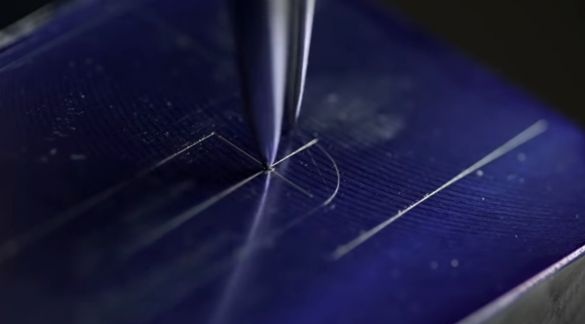

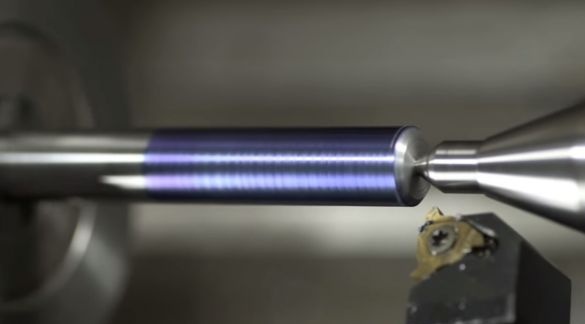

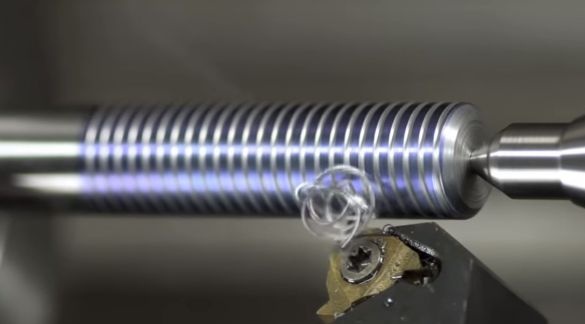

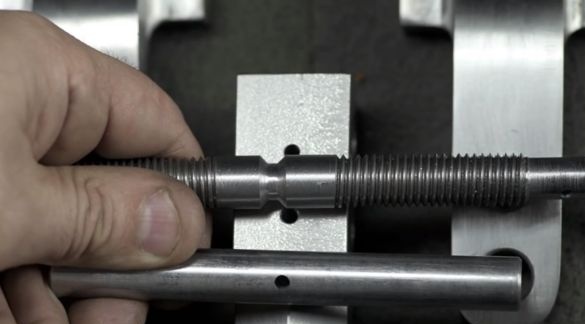

Here is another workpiece, it will be a clamping screw. First cuts the right thread.

Then he removes the left irregularities on the workpiece with a file and a metal brush.

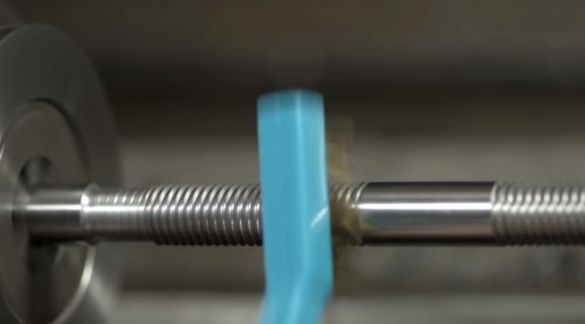

At the base of one of the jaws cuts the right thread.

The second one needs a left-hand thread. And the left tap. What to do?

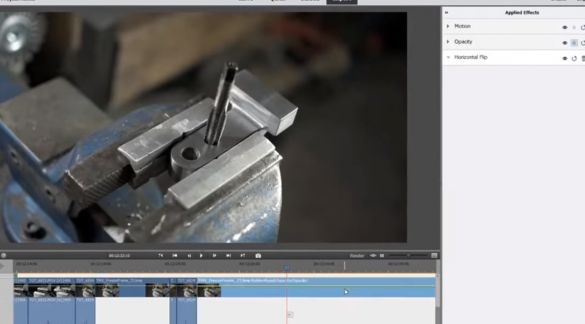

Tony simply unfolded the photo and cut the left-hand thread.

Almost everything is ready.

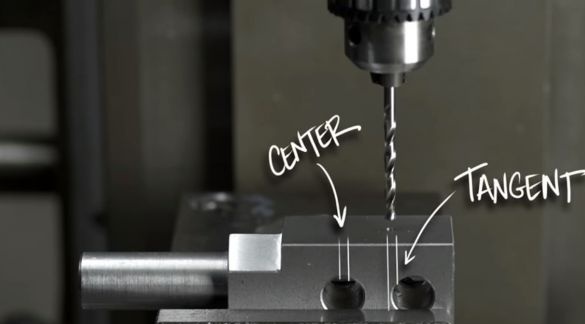

Now you need to drill holes for the keys in the base.

Also in the screw I made a groove for the keys, and in the guide I drilled a hole in the center. Fixes both parts, clogging the keys.

Also fixes the handle on the shaft.

That’s all done.

In a vice the tool is fixed for a hexagon of the basis.

And on the desktop - just inserting the round part into the hole.

Thanks to the author for another idea and excellent performance of a special clamp, we take it to the piggy bank! Thanks also for the presence of humor.

Good mood to you all!