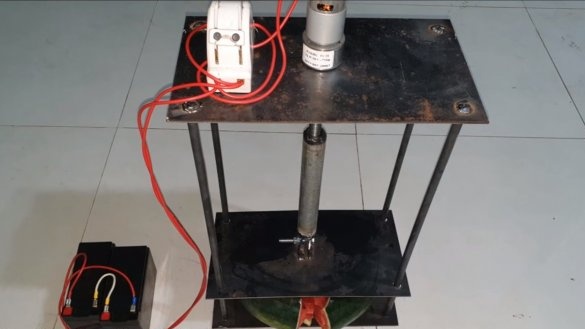

Hello everyone, I propose to consider instructions for the manufacture of a small press that is capable of running on battery power. Using it, it is convenient to glue sheet material, for example, plywood or paper. The strength of the press is enough to crush a watermelon or an orange.

The machine works from a source of 12-24V, a small motor with a gearbox is used here. In fact, a well-known and reliable engine for home-made machines is used by everyone. Made from simple and affordable materials. If you need such a machine in your home or if you are interested in what the geared motor is capable of, I suggest that you consider the manufacturing instructions in more detail.

Materials and tools used by the author:

Material List:

- ;

- battery or power supply (12-24V);

- threaded rod and nuts;

- Sheet steel;

- steel rods (round timber);

- steel pipe (round);

- switch (from the author at 30A);

- paint;

- wires.

Tool List:

- grinder;

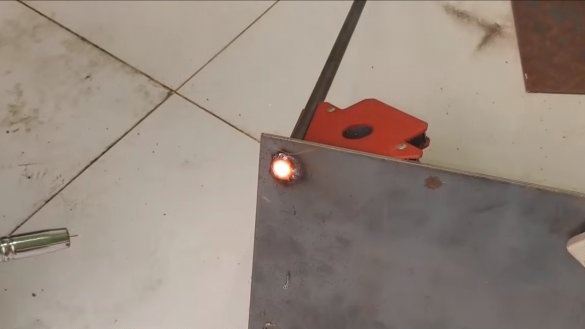

- welding machine;

- drill;

- drilling machine;

- the pendulum saw.

The manufacturing process of the device:

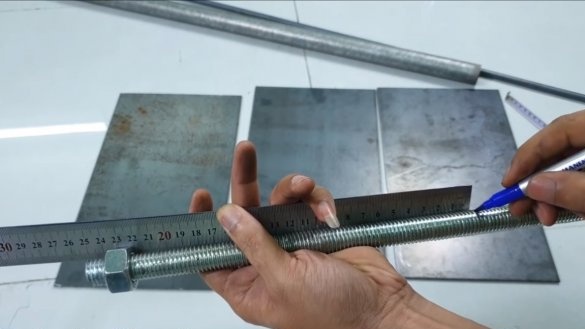

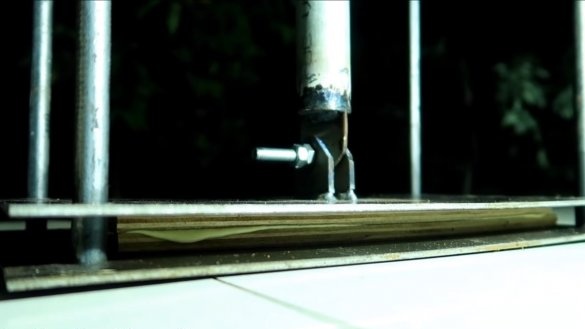

Step one. Production of a working shaft

The working shaft is a threaded rod. The smaller the thread pitch, the more powerful the press will be. To begin with, we need to fix the threaded rod to the motor gearbox shaft. To begin with, we drill a threaded rod clearly in the center so that the gearbox shaft enters it. Next, we need to fix the shaft, for this we perpendicularly drill a hole, cut the thread and wrap a screw.

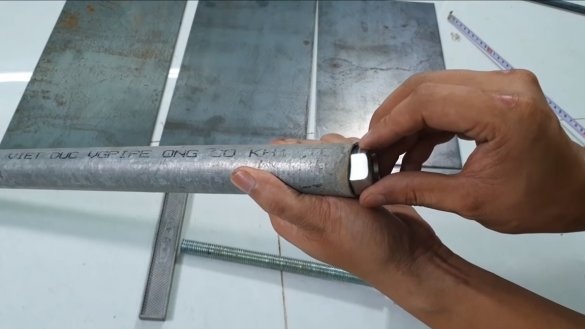

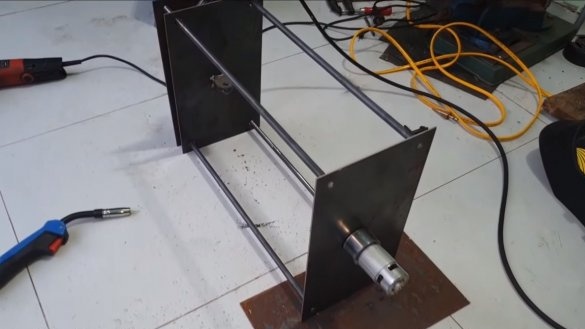

Step Two Cylinder

The machine is designed so that the threaded working shaft is wrapped or turned out of the cylinder, which is a piece of pipe. We need to weld a nut to this pipe, but for reliability we can have two. In this case, the main thing is to choose a pipe whose inner diameter will approximately correspond to the size of the nut.

On the other side we need to weld a loop, its author makes of sheet metal.

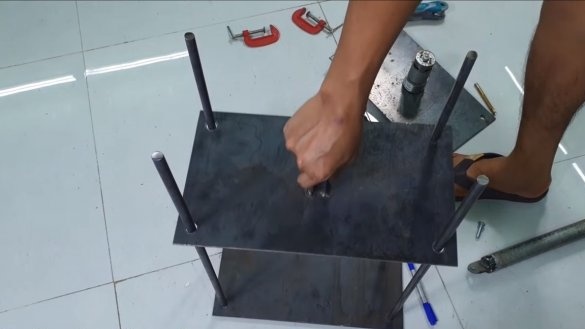

Step Three Frame manufacturing

The frame of the machine is two rectangular plates welded together with steel rods.In the upper part there will be an engine, it is fastened with two screws. And in the lower part we weld two ears for fastening the “cylinder”.

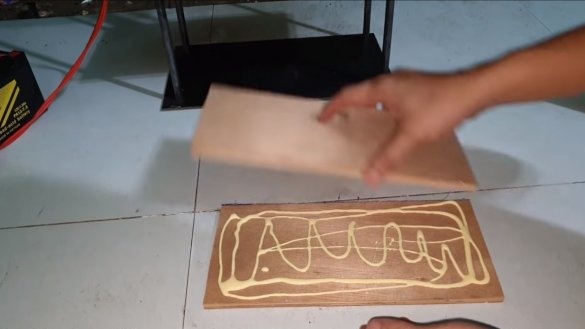

Step Four Assembly and testing

We assemble the machine, install the working shaft on the gear shaft, tightening the screw. We fix the end of the cylinder with a bolt and nut to the base. We paint the car so that the metal does not rust.

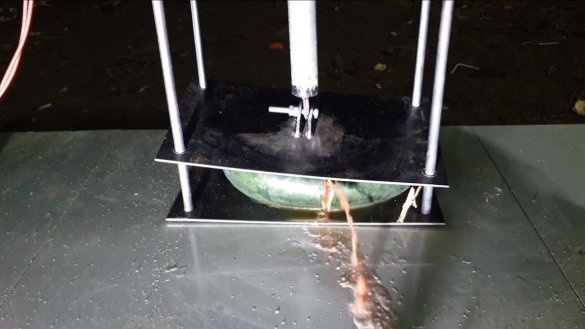

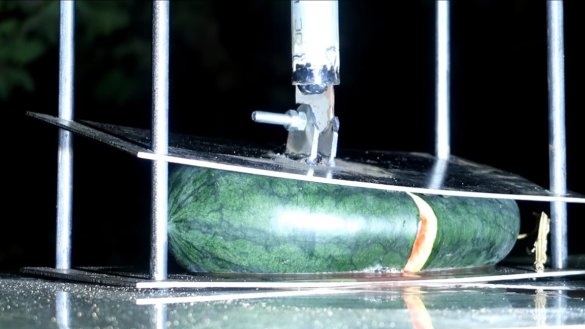

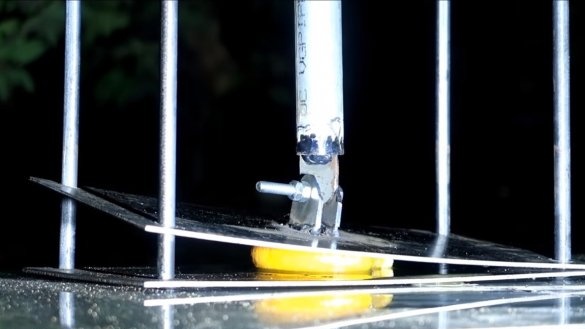

That's all, the machine can be tested. The author supplies power at 24V, at this voltage the engine runs at the maximum of its capabilities. The strength of the device is enough to easily crush a watermelon. Also, the author easily glued two sheets of plywood. At the end, install a good switch, designed for high current, the author has it at 30A.

That's all, on this homemade over. I hope you enjoyed the project. Good luck and creative inspiration, if you decide to repeat it. Do not forget to share your homemade products with us!