Greetings to all lovers of crafting something from nothing do it yourself.

Recently, for once, a straightening hammer was needed for work. In our small arsenal, there was no hammer with a round striker. You can of course go for acquaintances, but to beg the tool is not our method. They made their hammer, and not simple but space.

Tools needed.

1. Welding inverter.

2. Angle grinder.

3. Sharpening machine.

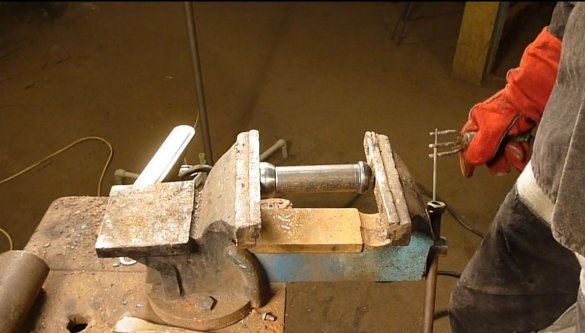

4. Vise.

5. Tap.

6. Electric drill.

7. File.

Materials required.

1. Two broken ball joints.

2. Steel pipe Ø 20 mm.

3. Steel pipe Ø 15 mm.

4. Steel bar Ø 10 mm.

5. Stud Ø 8 mm.

6. Steel balls for pneumatics.

7. Sheet plastic.

8. Textolite.

9. Epoxy resin.

10. Pasta GOI.

11. Paint.

12. Sandpaper.

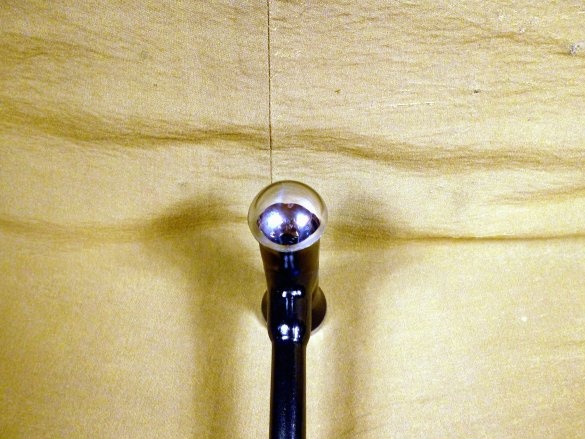

The strikers of the future hammer were made of ball bearings, and one firing pin was left round, and for the second one half of the ball was cut and the firing pin turned out to be flat.

From the pipe Ø20 mm, we cut off the necessary length for the hammer body. I do not knowingly write the dimensions, since the hammer, and in particular the length of the handle, must be calculated individually, for ease of use.

To the ends of the pipe segment Ø20 mm. weld the strikers.

We clean the welding seam on the grinding machine.

We cut the slice on a flat striker with a grinder using a flap disc.

We clean the steel bar from rust, it came across to us a little not at all new.

For the base of the hammer handle, cut the bar and hairpin. From pipe Ø 15 mm. cut two pieces of 10-15 mm.

We weld the pin to the bar.

The seam, of course, we clean.

We weld the base of the handle to the body of the hammer, and so where without stripping.

With pipe segments Ø15 mm, we strengthen the welds, for safety, so to speak.

As a result, we have such a semi-finished product.

In order to make a space from an ordinary straightening hammer, you need to add a secret ingredient. To do this, drill a hole in the hammer body.

And we pour metal balls for pneumatics inside.

The hole is of course welded.

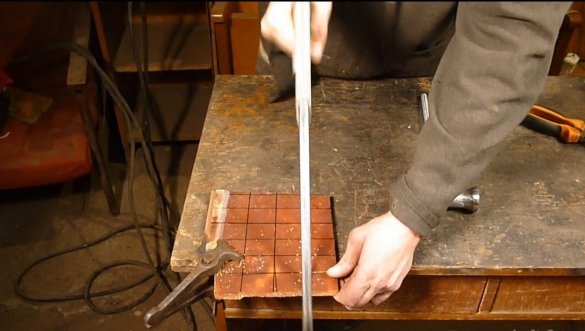

For the manufacture of the handle of the hammer we use sheet plastic. Cut 3 by 3 cm squares.and drill in the center of the hole.

The top is made of PCB, since it is stronger than plastic. We drill a blind hole and cut the thread for the stud.

We collect the handle of the hammer. We glue the plastic squares onto epoxy. We also put two rubber gaskets, they will hide possible assembly defects.

We attach the shape to the handle first on the grinding machine, then with a file, at the end we clean the hammer with sandpaper.

We polish the handle and hammer head on a felt circle using GOI paste.

It remains only to paint.

Space straightening hammer is ready.

And it’s cosmic because, according to the Internet, such a hammer design was invented specifically for working in zero gravity. I don’t know whether this is true or not, but the fact that this hammer doesn’t bounce off the surface has been personally verified.

All good and good luck in work !!!

A video on making a hammer can be seen here.