The main problem with this operation is that the leashes "sit" very tightly on the shaft, often "sour" and - especially in the case of "older" cars - "stick" to the attachment point. In these cases, it will be necessary to use force, but then there is a chance to damage either the leash itself, or its seat, or a plastic “apron” and even the windshield itself.

To simplify the removal procedure and to exclude the use of brute physical force (and, therefore, the risk of breaking, crushing, or scratching something), the device is called for, which the author of the TEXaS TV channel proposes to make on his own, namely, a simple but effective remover.

There are several options like “homemade», Manufactured according to the same pattern. For example, in addition to a stripper for leash wipers, in the same way you can create (resize) a device for removing generators and bearings. Also similar fixtures sold at the store. The cost of a metal puller starts at about 400 rubles (and high-quality - more than 1000).

However, the real "inhabitants of our site" make all useful devices themselves. In addition, you will need for this purpose only two washers, a bolt, an elongated nut and a pipe segment, as well as a vise, a grinder and a welding machine, to connect them together.

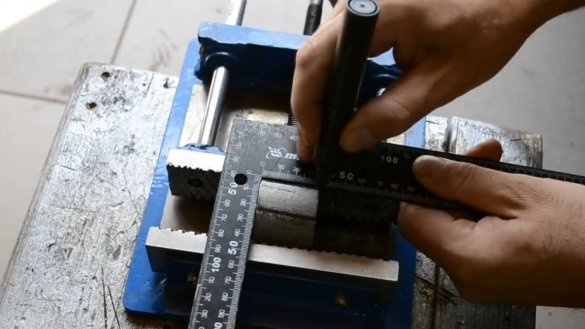

Step 1

First of all, in the pipe segment, we need to make a cutout corresponding to the width of the glass holder leash. Clamp the part in a vise and mark the cut line with a square, then carefully cut it with a grinder.

Step 2

Next, we customize our sawn pipe section - by crimping - under the washer so that it fits snugly at one of its ends.

Now we need to “weld” this washer and then “weld” the nut to it so that its hole coincides with the hole of the washer.

By the way, the author uses the idea of a long nut for a reason: its use allows to reduce the backlash of the bolt, and also reduces the load on the thread and, thereby, increases the service life of the "amateur" puller.In addition, thanks to the elongated nut, it is convenient to fix it with a key.

Step 3

To the opposite end of the pipe section we weld a second washer. It will be necessary to make a cut in it, so that it enters the lower part of the puller between the shaft on which the wiper leash is worn and the base of the leash itself (for this, the washer hole will most likely have to be expanded).

Our wiper holder removal tool is now ready. Now it remains only to check it in work.

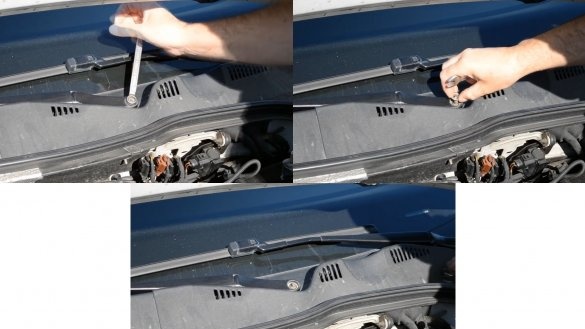

Puller in action

To remove the wiper blade using our device, first remove the plug and unscrew the fixing nut on it.

After that, install our puller, and fix it so that the lower part of the bolt rests in the center of the shaft, on which the leash is worn. Check that there is no skew.

Now - using a pair of wrenches - we hold the puller with one hand, and with the other we begin to tighten the bolt. Under its influence, our device will gently push the wiper leash from the shaft. When it moves from the attachment point, the resistance will decrease and it will be possible to continue to tighten the puller bolt by hand.

As a result, the wiper leash is removed literally in a couple of movements and at the same time nothing is damaged, not broken or scratched.

Such a fixture (made, according to the author, in about 30 minutes) will not be superfluous in the arsenal of home-made garage accessories by a motorist, since it saves time in the event of removal of “soured”, “stuck” or just extremely tightly “sitting” in the mount holder janitor. Also, using this puller, you do not need to use a hammer and other percussion instruments, wasting your own forces and free time. Plus, it turns out - albeit small - but financial savings.

The idea, of course, is not new, but maybe someone will come in handy.

That's all, good luck on the road!