And again, good day to all. In this article, the author of the channel “Mr SunY” will show how he collected such a straightforward device for cleaning the threaded part of the bolts.

And he needed it for this.

Materials:

The corner is metal.

Canvas for metal files.

Bolt.

A spring of this type.

And a rivet.

Instruments:

Angle grinder with cutting wheel

Welding machine

Hammer

Drill

Marker

Drill.

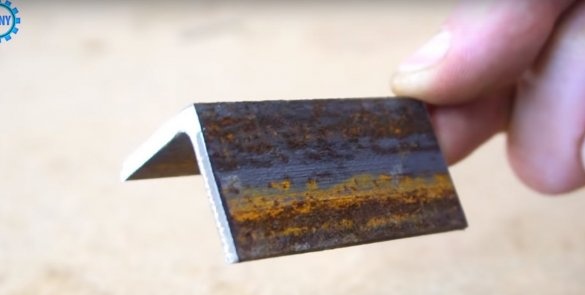

To begin with, the author will cut a small piece from the corner.

Then in this place will make a hole.

After will make a transverse cut, as shown in the photo.

The canvas will be installed in the cut and mark the place of the future hole.

After that he will make the same hole.

And setting the canvas in place, fix it with a rivet.

Then on the second wall of the corner, the author will also make a cut.

Like this.

The next step, he will weld the bolt to the corner, as shown in the photo.

And slightly shorten the bolt.

After in the canvas will make a longitudinal hole and remove excess.

Something like this.

Then the author installs one edge of the spring on the bolt.

And the second will fix on the canvas.

Such a device turned out.

Bolt test with a very dirty and clogged thread.

Result.

And that's all for me. Thank you all and see you soon!