Good day to all. In this article, the author of the channel “Mr SunY” will demonstrate to us how to assemble a tool similar to a laser level from a laser pointer. And so who are interested in reading on.

Materials: wooden beam.

Cardboard sleeve from stretch film or paper towels. Can be replaced with PVC pipe.

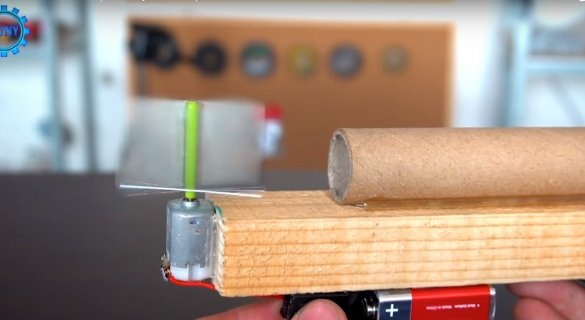

Electric motor from a toy car.

Battery "Krona"

Contacts to her.

This type of switch.

A small mirror.

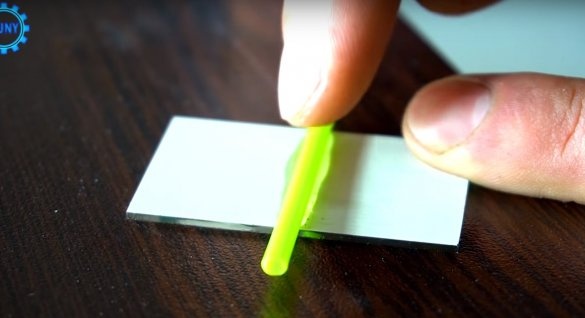

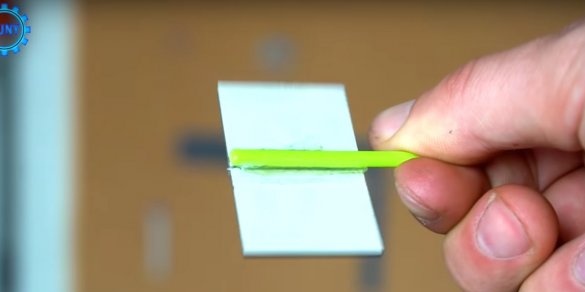

A plastic tube from a candy or from something else, the main thing is that its inner diameter matches the diameter of the motor axis.

Laser pointer.

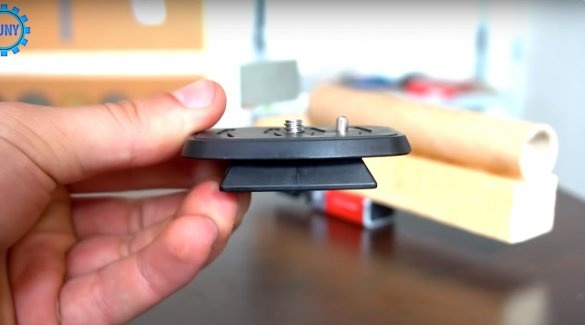

Tripod for the camera.

And a nut of the right size.

Materials:

Nail file for metal.

Marker.

Roulette.

Drill.

Drill.

Hammer.

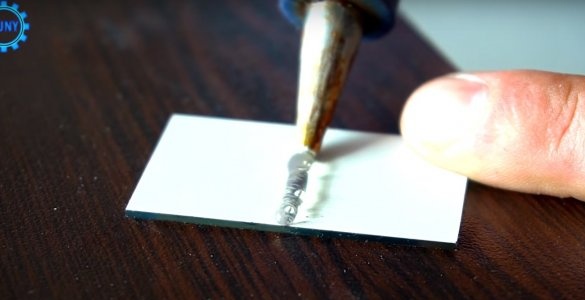

Soldering iron.

Tin and rosin.

Glue gun.

And the rod is silicone.

The author sawed off a piece of 200 mm from a bar.

Then paste a cardboard sleeve on one side.

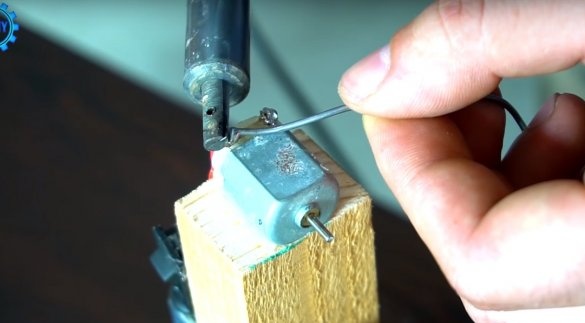

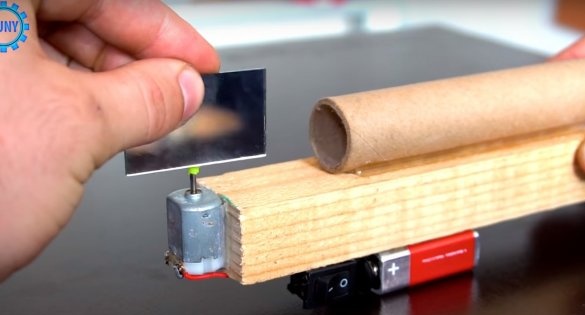

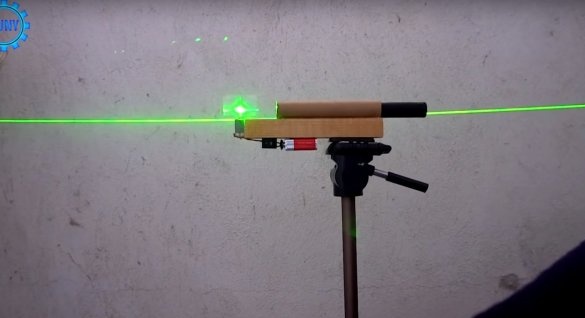

After the motor is glued to the end of the beam.

Like this.

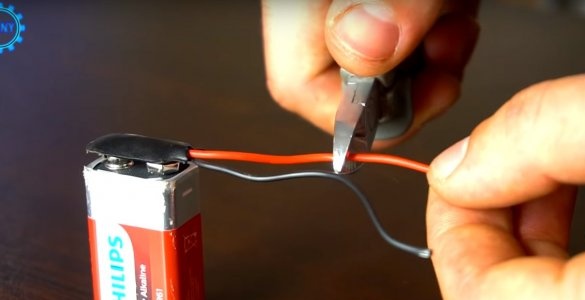

Next, establish contacts on the crown.

The author will divide the red wire into two parts, it will go through the switch.

Then the red motive from the battery will be screwed to one of the contacts of the switch, and the author will screw the second piece of the red wire to the second contact of the switch and the motor.

After sticking the battery to the bottom of the bar.

Next to stick a switch.

After soldering the wires.

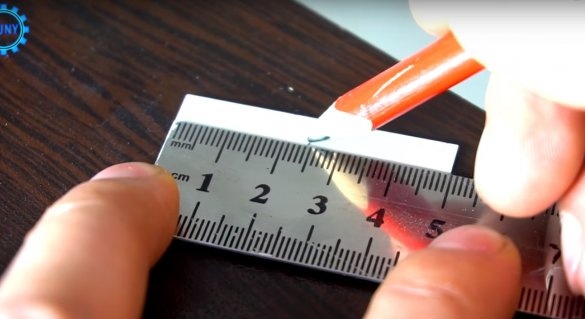

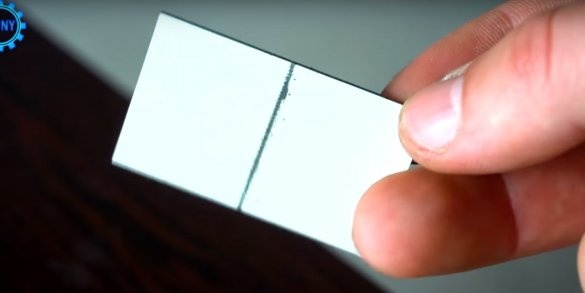

Next, the author marks the center on the mirror.

And glue the straw from the candy.

After installing the mirror on the axis of the motor.

Verification

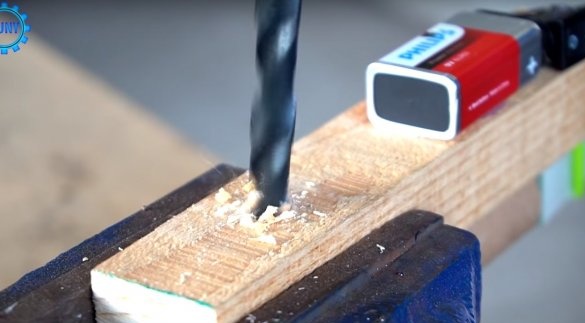

Further in this place the author will make a hole.

And install the nut.

Then install in the nut, the mounting plate of the tripod.

A laser pointer in a cardboard sleeve.

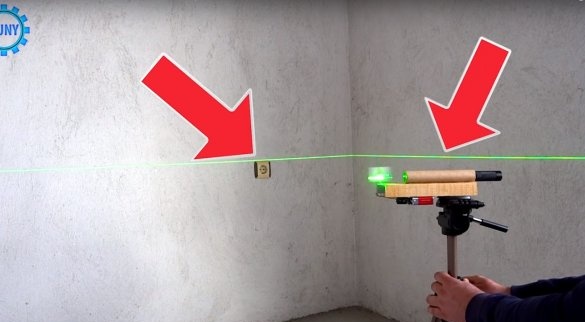

Here homemade and ready.

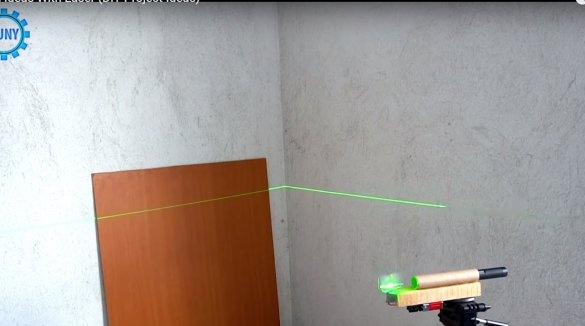

The author will install the finished homemade product on a tripod.

And start the test.

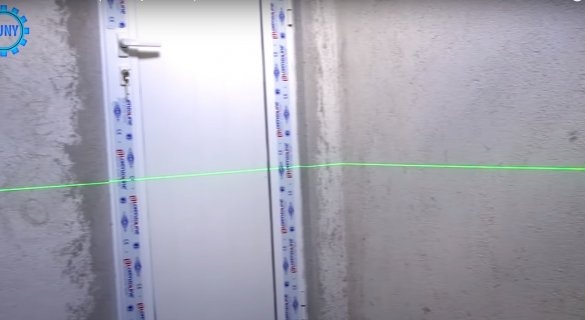

Result.

You can adjust not only the height and angle, but also you can change the position from horizontal to vertical.

And that’s all for me. Thank you all and see you soon!