Hello fans to craft, today we will assemble a large and powerful car. It will be about a tape sawing machine. With such a harsh machine, massive logs can be cut. The machine does not pay attention to either knots or to the type of wood, it cuts everything. Such a machine can cut boards, its performance is in no way inferior to many circular saws. The author assembled such a machine from wood, this material is not very reliable and even dangerous for use, however, the machine works perfectly. But no one bothers you to use iron and other strong materials for its manufacture. If homemade Interested in you, I suggest studying the project in more detail!

Materials and tools used by the author:

Material List:

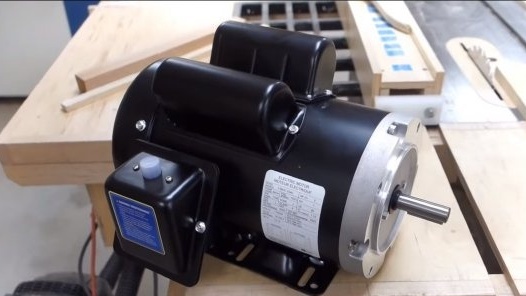

- engine (characteristics unknown);

- MDF or plywood for wheels;

- bars, boards;

- bearings with housings, axles;

- bolts and nuts;

- Belting;

- silicone or similar glue;

- threaded rods;

- corners, bearing;

- 4 castors for trolleys;

- cutting tape.

Tool List:

- ;

- spanners;

- tape cutting machine;

- lathe;

- Miter saw;

- a circular saw;

- drilling machine;

- clamps, chisels, hammers, tape measures, etc.

Homemade manufacturing process:

Step one. We make wheels and a pulley

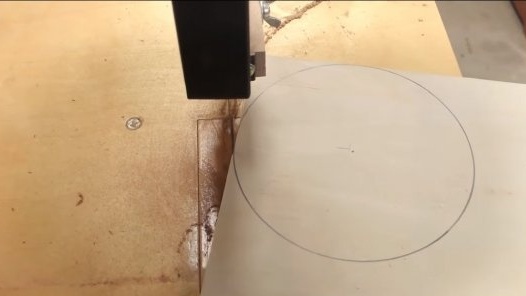

To begin with, we’ll make two wheels, we need strong sheet material, you can use MDF, but plywood will be the strongest if it is glued in several layers. We cut two circles, for cutting the author uses a tape cutting machine.

You also need to make a pulley for the drive wheel, we will have large sizes to get high torque, it is he who is important in such a machine. We also make a pulley from plywood, cut out a circle, and then grind a groove on a lathe.

We assemble the drive wheel, fasten the pulley to it, and also drill a hole for the axis. We will install bearings on wheels, drill holes for bolts and fasten them.

The wheels must be balanced, otherwise the beating will lead to strong vibrations and unstable operation of the machine.

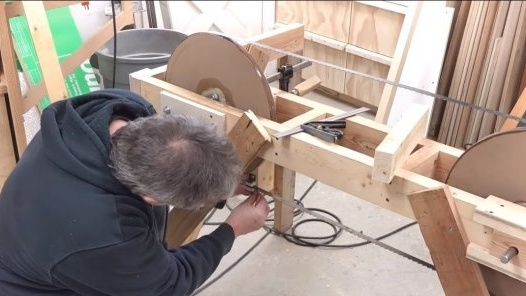

Step Two We assemble the frame for the machine

We make the frame for the car, it must be strong, it is on it that the wheels and engine will be fixed. Here we need a beam or thick boards. We cut them into the necessary pieces and then assemble the structure. Here you need to maximize the use of good long wood screws.

In the process of assembling the frame, wheels are installed, for the axis of the driving wheel we drill holes in the frame, it will be fixed motionless.

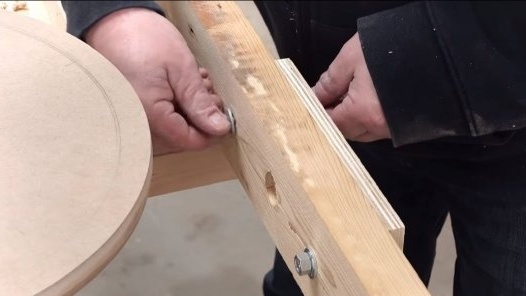

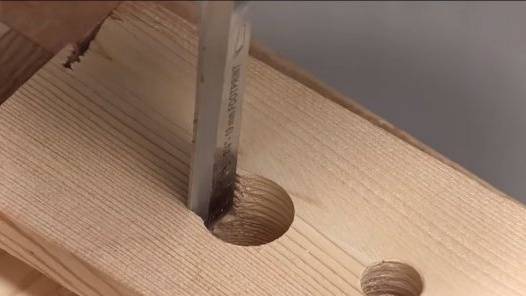

As for the driven wheel, you need to make a slot for it so that the wheel can be moved away from the drive wheel, thereby pulling the cutting tape. Just drill a series of holes, and then combine them with a rasp. The author makes the tension device from the boards, we will pull the driven wheel with two threaded rods with nuts.

At the end of this step, the author lubricates the wheels with silicone or similar glue, this is done so that the cutting strip has good adhesion to the wheels.

Step Three Feet and engine

We install the legs on the manufactured frame, in the end we get a table. The legs should be strong, put the spacers and do not regret the screws. The table must be stable, otherwise, if it falls during operation, everything can end tragically.

We install the engine, for this we fasten a sheet of chipboard or other strong sheet material to the frame. Well, then we drill holes, pull the belt and securely fasten the engine with bolts and nuts.

The engine can be turned on, during the operation of the machine the author noticed that the tape rotates slowly, as a result, it was decided to carve a larger pulley from the tree and install it on the engine shaft.

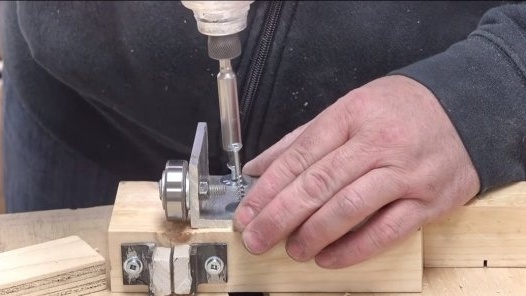

Step Four Emphasis for tape

For the detachable tape, it is necessary to emphasize, otherwise, when we press on it, it will shift. For the manufacture of stops we take measurements and cut along the length of the bars. We have two stops, the tape will abut against the bearings. We fasten the bearings to the corners with bolts and nuts, but we fasten the corners to the bars.

It is also necessary to make stops so that the tape does not slip off the bearing, here we use the corners, and to reduce friction, you can screw pieces of wood, textolite and so on to the corners.

Step Five Platform and Tests

The machine is ready, we will make a feed device for it, in fact it is a trolley on which we will load the material for cutting. We assemble the cart from strong boards or bars, we fasten the wheels from the cart to it, the rotary assembly can be brewed, the platform should only travel in a straight line.

It is also necessary to make “rails” so that the machine can be installed directly on the ground. We knock down the desired design from the boards.

The machine is ready for testing, the author goes for a massive piece of tree trunk, which he barely barely rolled to the machine. We load the barrel on the platform, start the car and move the platform to the cutting tape. The machine easily cuts wood, even strong and knotty.

To simplify the process of work and safety, it is possible to tie a rope to a movable platform and drag it on the other side with a winch, while being at a safe distance from the machine. Standing in front of a rotating tape can be deadly if the machine breaks down.

The car turned out interesting, I hope you liked the project. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!