I welcome fans to craft, in this instruction we will discuss how to equip a scooter with an electric motor. The author used a scooter already old, with the engine failed. In general, apart from the axis of the rear wheel, the design of the scooter does not change much and therefore, if desired, the scooter can be restored.

According to the author, homemade It can accelerate to a speed of 50 km / h. The drive from the engine is carried out directly to the rear wheel, but if you connect it to the gearbox, you can get a higher torque, if necessary. If the homemade product interests you, I suggest studying the project in more detail!

Materials and tools used by the author:

Material List:

- old experimental scooter;

- 48V battery (the author assembled from lithium cells);

- (and electronics for him);

- iron plates (for fasteners).

Tool List:

- lathe;

- ;

- ;

- or a drilling machine;

- spanners;

- a screwdriver.

Homemade manufacturing process:

Step one. Scooter disassembly

We start the process by disassembling the scooter, we need to remove the engine, and after this removal we proceed to disassemble. We remove the generator with the rotor, as this is overweight, you can also remove the crankshaft, but it will not bother us. Remove the variator cover and disassemble the variator as well.

Among other things, the author decided to disassemble the gearbox, the drive is carried out directly to the rear wheel. Probably the engine torque is enough to ride a scooter. Remove the rear wheel, as well as the rear axle.

Step Two Engine installation

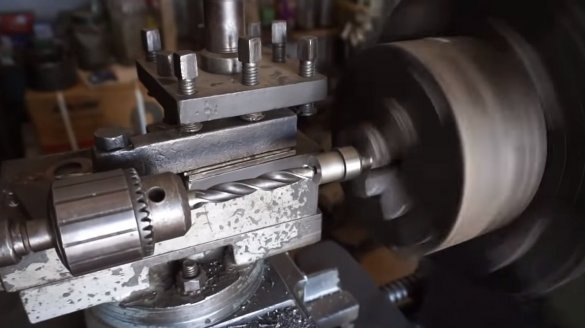

We begin to install the engine, for a start we need to joint the engine shaft with the axis of the wheel. In the axis, you need to make a seat so that the threaded part of the motor shaft enters. Well, then we weld the shafts together as tightly as possible.

That's all, now we install the engine, install the wheel on the axis. The engine needs to be fixed with a bracket, we assemble it directly on a scooter of iron plates. We cut off a piece of the plate, drill holes and fasten it to the engine body. And we fasten the second plate to the mounting ears of the engine.As a result, it remains to weld the plates together, and the engine is installed.

Step Three Assembly

We are assembling a scooter and now we only need to install the battery and electronics. As for the battery, the author assembled it from 18650 lithium cells, you can get these from old batteries from laptops, but all of them need to be checked and workers selected. The battery should produce a voltage in the region of 48V, the battery capacity of the author is 30Ah. We put the battery pack under the seat, we immediately position the speed controller, as a result, the trunk closes, water, dirt and robbers will not get here.

To control the engine, we install an electronic throttle handle and conduct wiring along the frame.

That's all, the scooter is ready, we charge the battery and go for tests. The author pulls away quite easily, which means that there is enough torque. How much you can ride on a scooter remains unknown, the maximum speed, according to the author, is 50 km / h. It would be nice to install a voltmeter on the car to control the level of battery charge.

This is the end of the project, I hope you liked the homemade work and you found useful thoughts for yourself. Good luck and creative inspiration, do not forget to share your ideas and homemade things with us!