Such a machine will be needed if there are work to be done with a large number of threading operations. It will greatly facilitate labor costs and save a lot of time. This machine, except for one part, is assembled from recycled materials.

Tools and materials:

-Old Soviet photo enlarger;

-Collet;

-Metal frame;

-Sheet metal;

-USHM;

-Drilling machine;

-Welding machine;

-Metal shaft;

-Sleeve;

-Spring;

-Milling machine;

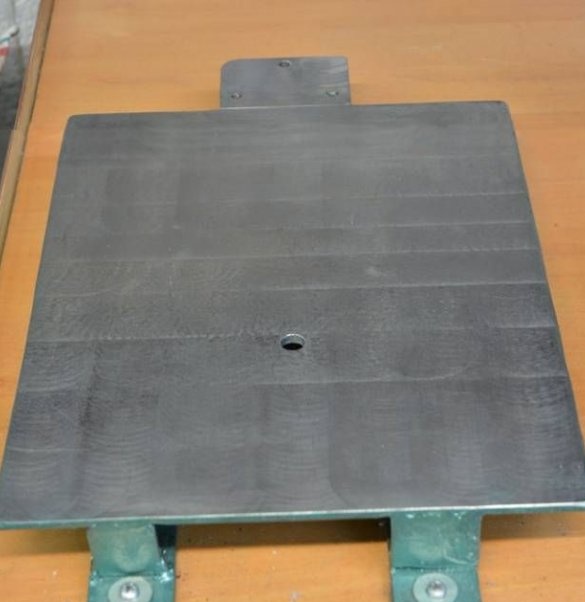

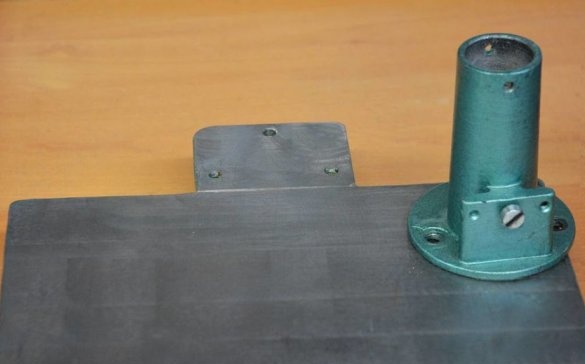

Step One: Foundation

The master made the base from an old metal frame and an iron 6 mm plate. Unnecessary parts were cut from the frame, and the plate was cleaned of rust. Frame size 265 mm x 240 mm, plate 300 mm x 240 mm.

Then the master milled the frame and welded a plate to it. I screwed the legs from the bottom of the base, and the rack mount at the top.

Step two: spindle and shaft

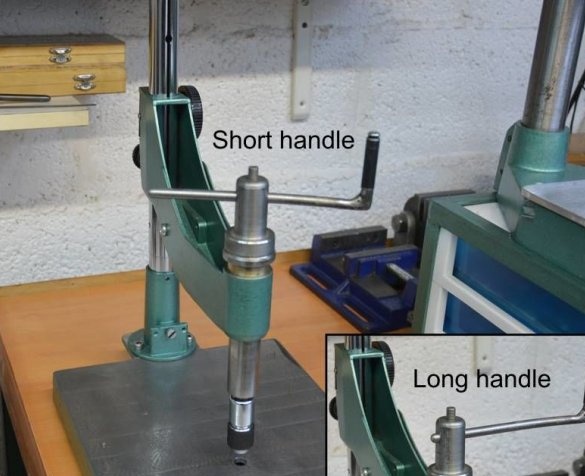

The only part the master acquired is the spindle. The spindle is mounted on the shaft using a tetrahedron. In the center of the shaft, the master drilled a hole for him. On the opposite side of the shaft, a transverse hole was drilled at the end and installed a knob. In the middle part of the shaft there is a thrust sleeve for the spring.

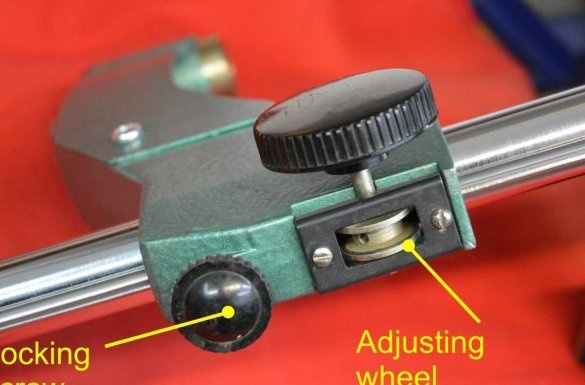

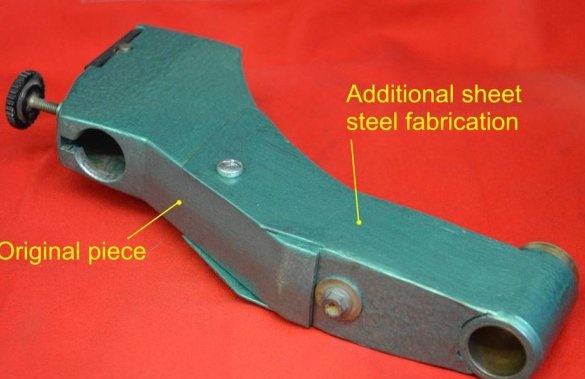

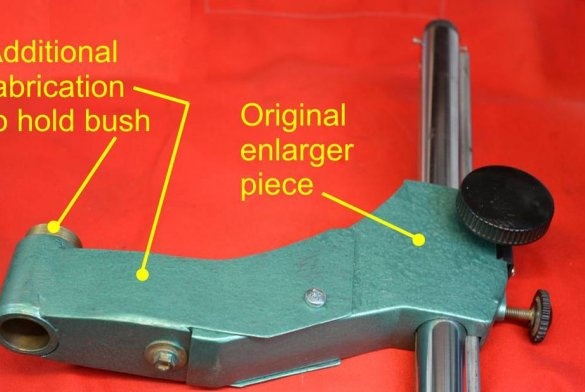

Step Three: Magnifier

The choice on the rack magnifier fell because of its ability to move up and down. To install the shaft, the master secured a sleeve in the hole.

First, the master installed a spring on the shaft. but later removed. The spring did not make it possible to understand the degree of pressing on the workpiece. The master also made another handle for cutting large diameter threads.

According to the master, the tool turned out necessary and convenient. The height of the workpieces from 0 to 275 mm.

The whole process of manufacturing a machine for cutting threads can be seen in the video.