Hello, dear visitors of the site.

Now I have started the "construction season" (I am renovating an old house do it yourself), therefore, to do home-made for the sake of "rest", as usually happens to me, I now have no time, and there is no need ...)))

But now, having encountered on this site a misunderstanding of the advisability of doing some homemade work, I decided to take the time to do it! ..))) "Question of honor" after all ...

Specifically, this article is a response to this comment here:

I am really looking forward to an article on the topic "How to make a rake with a spring, grinder, drill, welder and 5 hours of work, which cost 200 rubles in a store"

That is, a person who is sure that it takes five (!!!) hours of work to make a rake (read - "who knows nothing"), somehow painfully aggressively expresses his point of view, considering all other points of view to be wrong! !!

... You know ... More recently, I also did not understand what this should happen in this life, so that I started making rakes.)))) ... But, nevertheless, I didn’t insist then on the fact that no one will ever have to do this! And even more so, I would not scoff at it in such a manner! ...

..But, it happened !!! .. I really had to make a rake ...))) The circumstances that led to this are very simple. While renovating the house, I demolished the partition wall. He carefully stacked the bricks (useful), and the mountains of broken lime plaster (the layers were about five centimeters on both sides), he took out with a wheelbarrow to the driveway. It is still uncoated, just covered with gravel, and there are several deep puddles on it. It was in these puddles that are now dry that I poured plaster. The technology is simple - I pour out a few wheelbarrows, level it out slightly, then roll the wheels of a minivan several times, rolling back and forth. At the same time, the plaster is crushed and compacted. A few more wheelbarrows ... Again, leveling, rolling out ... Double use - and the road is leveled, and the garbage is disposed of ...

... took out ...Poured. I went for a rake ...

And then there’s no rake !!!

That is, of course, I have them! Only now they broke down in the fall and I took them to the basement under the apartment to repair ... And, as is usually the case, this repair was delayed for six months! )))) .. In the spring, when my wife was already engaged in her planting and flower affairs, and, on the way to the station, asked me, “Have you even made a rake? I will need today!”, I lied that “Of course, Darling! ... Only, I forgot to throw them in the car! )))) ... But my wife didn’t like the new ones, for some reason, and she constantly asks me to bring her old ones, and I constantly “forget”.))) ...

.. And now, I see that she is working right now with this very “unloved” rake !!! Imagine what will happen if I come up like this and say "I need a rake!"

...Not!!! Of course, I’m not a timid dozen! .. But it’s stupid to die in the color of years? !!! ... No ... I’ll look for another way!

And I found it!

Rummaging around in the remains of the "necessary scrap", I found a piece of the corner - twenty-five, several pieces of wire-eight and a piece of water pipe ... Quickly welded a rake, fortunately, at this stage of construction I often have to work "with iron", and therefore, welding and grinders are "in the expanded state" (No need to carry out, unwind, connect) ... I made them wide (about a meter). Then, having done my job, I wanted to cut them to "standard size", but my wife took them from me!)))) ... She said that such a tool is very, very suitable for her - it evens out the entire flowerbed in one pass! And what is heavy? ... So it's also better. He is needed only for one "final" passage ... "But those old ones, you still bring !!!"

And now, a few days after the events described, I see this comment! ... The blood boiled, and I could not resist!))) ... Maybe I didn’t find time to make another one (then not I took pictures and didn’t take time. There was no time), and everything would have remained ... Well, I came to a construction site, changed my clothes ... And then my wife calls and it turns out that I need to go back. In stock before departure - forty minutes. Start doing something at a construction site - no longer worth it!

But, I’ll have time to make another rake! )))

So....

"Our answer to Chamberlain!"

Materials:

1. Steel equal-angle corner 25 by 25 mm, 400 mm long.

2. Steel circle ("wire rod"). Trimming. Fittings are also suitable.

3. The pipe DU-25. (trim)

To begin with, I found everything I needed - a piece of the corner of the cutting wire rod and pipe:

From the corner I cut off with the grinder the segment I needed:

Then I started making teeth. So that they all turn out to be the same length, I decided to cut them according to the pattern. Since I worked “on my knee”, and not in a workshop, I just found a piece of an old board on the street, I drew a line perpendicular to the edge, marked the length I needed from the edge (estimated that it would be 70 mm), and cut off future teeth by applying a blank to this template:

At the same time, I cut one edge of the tooth perpendicularly, and the second - at an angle of about 45 degrees. This is so that the teeth do not sharpen then.

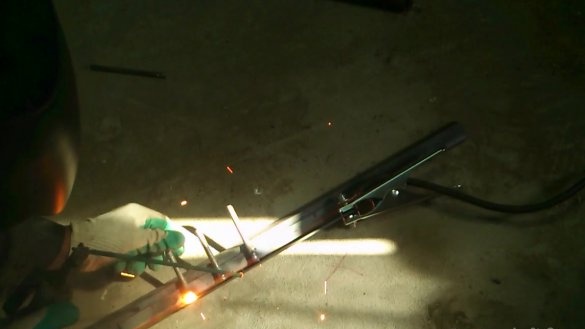

When the right amount was ready, I marked the corner into pieces of 50 mm, and began to weld the teeth by arc welding on the inside of the corner. At the same time, they arranged them so that the oblique cut at their ends was on the outside:

Now he turned over the rake blank, and welded each tooth from the outside:

Now we will begin to manufacture a seat for the handle. In the "scrap metal" was found a piece of an old, rusty pipe DU-25. Apparently - "gas", that is, thick-walled. But it doesn’t matter to me.

From it I cut a piece of the length I needed ... (I didn’t measure it. I cut it “so that it was normal”)))):

The pipe was very rusty, therefore, I lightly cleaned it with an emery-petal circle:

On the one hand, I made this cutout:

I put this piece of pipe on this corner cutout, leaving a sector cut at an angle in the upper part of the rake. And from the bottom side, where the cut-out fits snugly against the corner, I welded it with a solid seam:

After that, he turned the rake over, and using the same board as an abutment, he added the rest of the pipe with the "hammer-hammer method", thereby drowning its end:

Then it remains only to boil with a solid seam and this part of the mount:

It remains to drill a hole for the screw:

Well ... Well, they can be said to be ready ... It remains to make a stalk. Last time, creating the first version, I, as a handle, used a piece of reinforced polypropylene pipe that came to hand. (I’m just installing heating). This time there was no such pruning, but there was a normal stalk on which I once had a paint roller. (I primed them with walls). I took off the roller for a long time. The cutlery remained. I decided to use it:

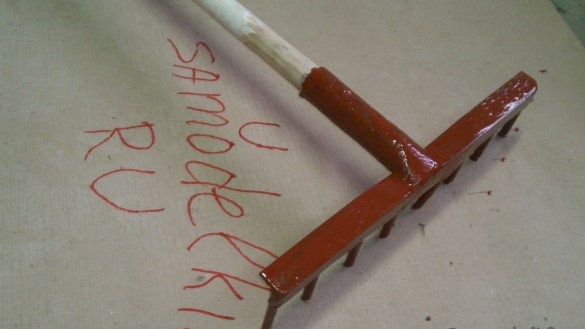

With a petal circle, he “fitted” his diameter a little, planted a rake and fixed it with a screw with a press washer. At the same time, in the same circle, slightly cleaned the rake itself:

I looked at my watch ... There is still time (The whole manufacturing process took about twenty minutes). I have already decided to “finish” it to the end, to give, so to speak, a finished look. I always have a primer for metal in my stock - the so-called “ship meerk”. So I decided to paint my product with it. It would be necessary to do this before screwing the screw ... Or, turn it out, paint the rake, and screw it in again ... But I really didn’t feel like it.))) So I just embellished everything, together with the screw ...

That's all! The rake is ready.

It took them not at all 5 hours to make it, as the ironic commentator wrote, to whom the presence of a “grinder, drill, welder” seems to be something outrageous ... And no materials were needed, besides that which was not needed, that was lying around .... So that, it’s not such a useless pastime to make a rake ...

He gave a bad example!)))))). This example is suitable only for those who only have a drill from the entire tool (everyone has it! Without it you are not a man !!)))) ... And who goes to the store if he needs one screw. ))) ... But what did such people forget on THIS SITE? )))

... I will say more. I made not only a rake ... From a garden tool, for example, I made somehow flat-hoes. ("Choppers", as we call them. And Ukrainians who come to us for work, call them "hats").

And, not at all because I can’t buy them ...))) It’s just that once I was with my wife in the country ... She, as always, enthusiastically took up the flowers ... I had nothing to do. .. The arm caught a cut two-handed saw and an old bicycle frame. And in an hour and a half I cooked four choppers of different widths. Just like that ... There is nothing to do from ... The wife, by the way, says that they are much more comfortable for her than the ones she bought ...

And from what I have done many times “along the way, on my knee” - these are knives. No ... Of course, these were not beautiful knives, with the right descents, and the right hardening ...)))). It just happened several times that the knife could not be found in the mess of the construction site ... Then it’s a matter of ten minutes (this is easier than a rake))). I sawed off a strip from the same saw in a cutting circle, gave the blade a petal shape, while sharpening it. Then he punched a couple of holes with a punch, riveted two plywood with exhaust rivets, and with the same petal shape he shaped the handle ... That's it! A normal (for my tasks) knife in my hand! ... And then he got lost, falling into a pile of building materials - and God be with him! Do not disassemble a bunch for his sake! ... Quickly one more he did ... So, faster ...

But at the same time, I also speak out with mockery at the subject of the work of those who, piling over a knife, spend a week or even more making it !!! Moreover, at the same time, buying (FOR MONEY !!!) materials for him. Indeed, one can also say: “Why do this? With this money, you can buy a set of knives at Fix Price!” ...

But he, making an exclusive knife, enjoys his work ... I, making a simple working knife, pursue a different goal - I save my time ...