Site visitors are already familiar with the work of this wizard, this and "Topographic" map of wood, like a wall panel " and "Wooden shoes-rollers from pallets" and a nutcracker, a giant knife, etc. In this article, the master presents material for making a giant plane. This is an exact copy of the half-cup No. 5 on a 3: 1 scale. Of course, such a product is of little practical use, although the half-jointer is also a worker, but the craftsmanship of the master is admirable.

Tools and materials:

-Wood of different species of wood;

- Clamps;

-Glue:

-Lathe;

Grinding machine;

-Tunga oil;

-Calipers;

-Taps and dies;

-Soldering iron;

-A circular saw;

-Drill;

Step One: Rear Handle

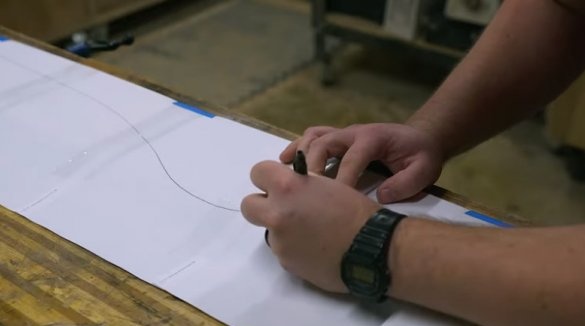

Making a half-jug master begins with the manufacture of pens. Glues several species of wood adhering to the pattern.

After gluing, the master cuts the workpiece.

Processes to the desired shape.

Step Two: Front Handle

The front handle is made of solid wood block. Cuts on a circular saw, processes on a lathe, grinds.

Step Three: Pad Walls

The walls of the pads are made of boards. The master cuts the board to the desired length. Dissolves it and evens out in thickness.

Cut to pattern.

Fourth step: the middle part of the pads (pads)

Next, the master cuts the board for the sole of the pads. From the top of the sole two pads will be attached, and already on them handles.

Sticks handles to the pads.

Glues the support part to the rear trim. A knife will rest on it.

Step Five: Bonding the Pads

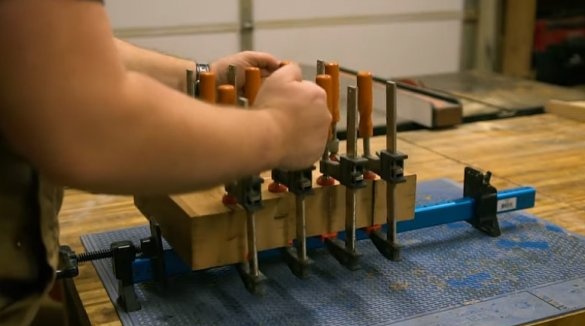

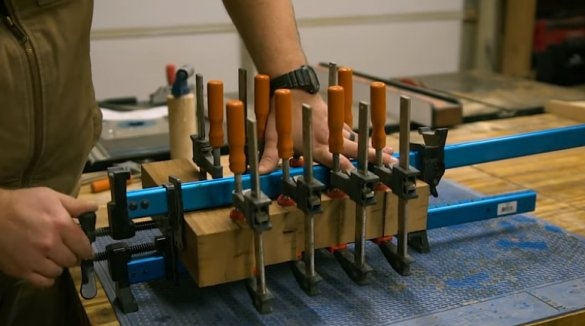

Now you can glue the pad walls to the sole.

Step Six: Cross

Next you need to make a cross.

Makes and sets the transverse regulator.

Seventh step: wedge

Cut the wedge.

Step Eight: Screw

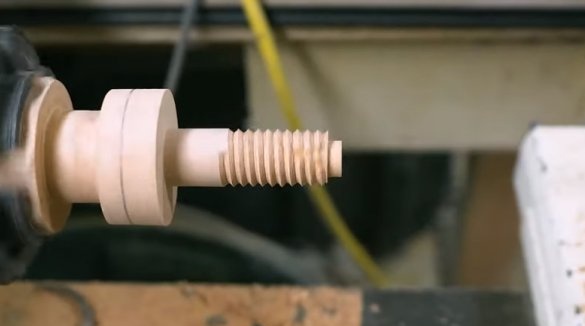

Turns a screw on a lathe.

Cuts the thread.

Makes a second screw.

Slices the slots on the head of one of the screws.

Screws fulfill a decorative purpose. The master drills holes in the handle and installs the screws.

Step Nine: Complete

There is very little left. The master puts the stigma. Grinds details of a half-joint.Some parts are painted with black paint, and some are treated with tung oil.

Then the master places two half-jugs, one original, the second made by him, in a box and sends to the exhibition in another state. Upon arrival, a blade made by another master was installed on it.

Product testing in business.

Here is such a giant half-jug made by the master. I would like to add that the master took first place at the exhibition, and this is not surprising.

The whole process of making a plane can be seen in the video.