And again, good day to all. Today, the author of the channel “Igor Konstantinov” will show how to quickly and inexpensively make a clamp, with a minimum set of tools.

TOOLS AND MATERIALS:

Vise

Nail file for metal;

File;

Gun for sealant;

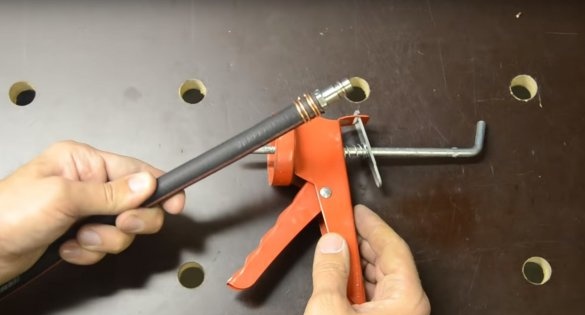

To begin with, the author will set the gun in a vice, then shorten the casing.

And cut the hairpin.

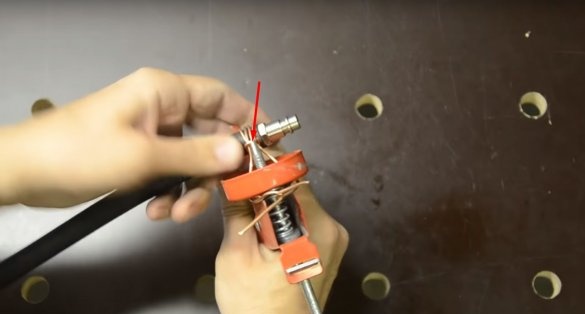

After, the cut edge of the hairpin was slightly honed.

Then he made a small slot under the wire.

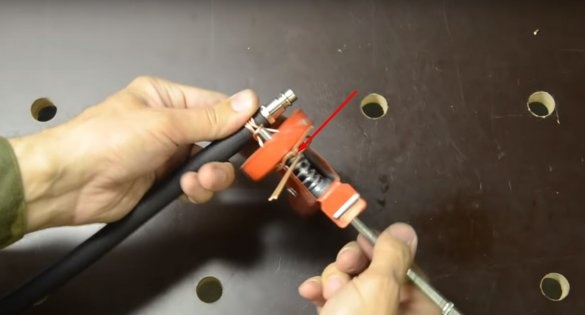

In order to process the hairpin, the author had to remove it from the holder (casing).

Now he collects everything in reverse order.

First: the locking element.

Second: spring.

Third: hairpin.

And all homemade ready.

Yes, and by the way, the author did not make any holes in the body for fixing the wire, since they already were in this model of gun.

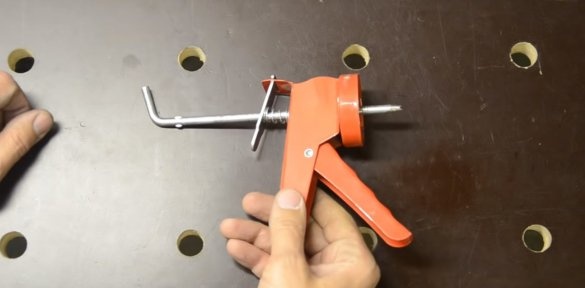

Well, now the test.

Installing a wire clamp.

Then, thread the ends of the wire into the holes of the clamp.

And captures them.

Next, install the clamp wire into the slot of the stud and proceed to tighten the clamp.

When working with this tool, while tightening the clamp, it is possible to straighten the wire.

And the rest, the principle of operation of this clamp is similar to everything else.

Result.

This homemade job coped with the task perfectly.

The thickness of the wire for clamps that this tool can handle should not exceed 2 mm.

Such a good and easy-to-manufacture tool, it turned out from the author today. I want to say to the author, many thanks for his homemade work.

And that’s all for me. Thank you all very much and see you soon!