I welcome all fans to craft, today we will consider how to make a small jet pump. With the help of such a device, boat models can be activated, and if you use a more powerful motor, it is quite possible to make a water scooter. Of course, with a certain refinement, such a pump can also pump water. The author used the 775 motor as a basis, its shaft develops enormous momentum, and it is perfectly suited for such purposes. The transmission of motion from the motor shaft to the working shaft occurs at an angle, the author solved this problem by installing a miniature cardan transmission. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- ;

- speed control for the engine;

- iron plumbing clamps;

- 5 mm brass rod (for shaft);

- coupling for connecting shafts (5 mm);

- a small plastic propeller;

- epoxy adhesive;

- ;

- plumbing parts (for housing).

Tool List:

- screwdriver;

- soldering iron;

- a hacksaw for metal;

- drill;

- scissors for metal;

- marker.

Manufacturing process homemade:

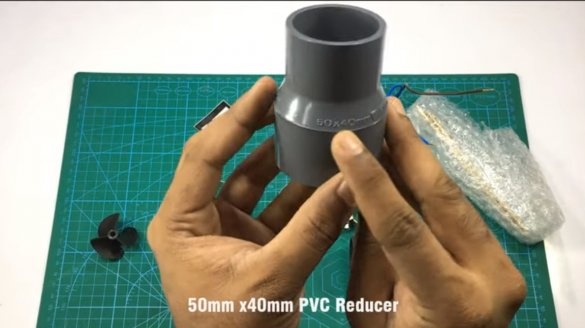

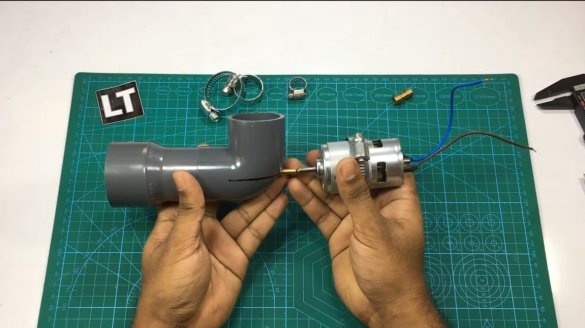

Step one. Housing

First of all, we’ll make a case for homemade work, here we need plumbing parts. As the main parts, you will need a cone-shaped part, as well as a corner, and for their connection you will still need a piece of pipe of the corresponding diameter.

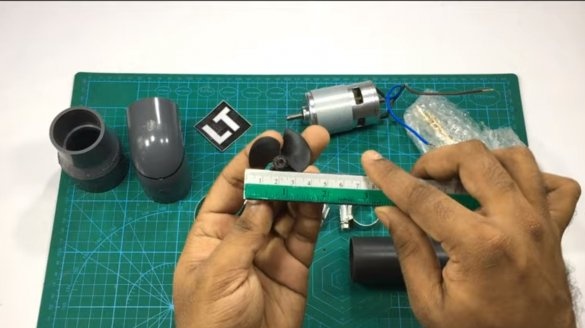

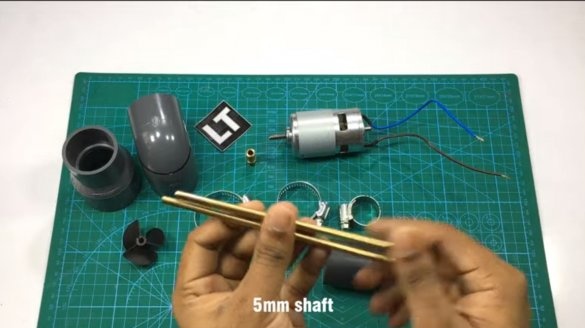

In the resulting housing, you need to drill a hole for the working shaft. The author uses a 5 mm brass rod as a shaft; brass is resistant to oxidation; therefore, it is excellent for such purposes.

We will also need to make another part of the body from the pipe, the engine will be fixed in it. To fix the motor, the author uses an iron clamp.

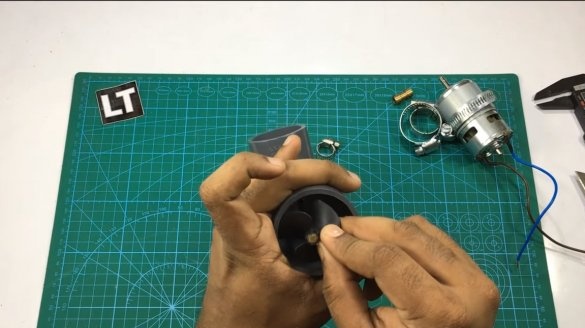

Step Two Sleeve

In the case you need to install a sleeve in which the working shaft of the device will rotate. For such purposes, we need a brass coupler for 5 mm shafts.We glue the coupling into the housing with epoxy glue, this will be the sleeve into which the working shaft will go with a minimum clearance. Due to the small gap, water will not leak through the sleeve. Of course, for reliability from the inside, it would be nice to install a rubber gland from the bicycle chamber.

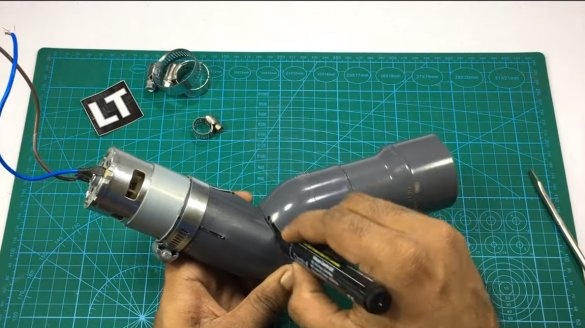

Step Three Cardan drive

The torque from the motor shaft we need to transmit at an angle. To solve this problem, the author bought a miniature gimbal. For reliable and durable operation of the cardan drive, grease it with grease.

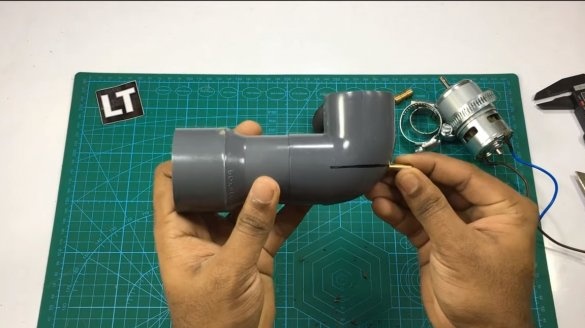

Step Four Assembly

The pump can be assembled, both parts of the body are interconnected using a bolt with a nut, and so that the unit does not move, we glue it with superglue. Additionally, all joints can be greased with epoxy glue, then the design will be solid, but the disadvantage is that there will be no access to the cardan drive.

That's all, after that our jet pump is ready, you can test. It is better to turn on homemade work through the speed regulator, since the 775 motors are quite powerful. The homemade water pressure forms quite strong, it is quite enough for a boat on the control panel. If desired, a protective grill can be installed on the pump, as a result, the boat will be able to sail in bodies of water with a moderate level of vegetation.

This is the end of the project, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!