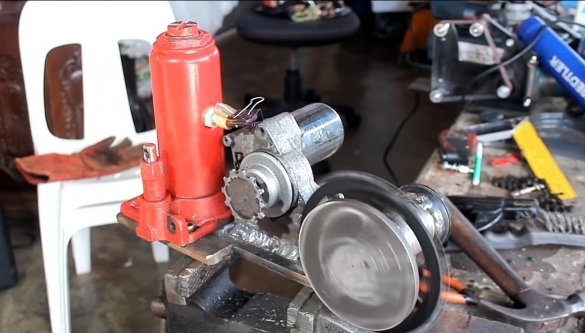

I welcome all fans to craft, today we will consider how to make a motorized hydraulic press. With the help of such a machine, it is possible to easily remove and install bearings, as well as other parts. The machine turned out to be quite powerful, it is built on the basis of a hydraulic jack of 4 tons. You can control such a machine by pressing a button, there is a small motor that drives the jack. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- hydraulic jack for 3 tons;

- channel for the frame;

- a small 12V gear motor (from a scooter starter);

- round timber;

- iron plates;

- springs;

- a small plastic tube;

- plastic ties;

- two sprockets and a chain from a bicycle;

- rear wheel hub from a bicycle;

- paint for metal.

Tool List:

- grinder;

- welding machine;

- vise;

- tape measure, marker;

- drill.

Manufacturing process homemade:

Step one. Finalization of the jack

First of all, we will need to modify the jack, namely, to make sure that the jack can work upside down. To do this, disassemble the jack, first drain the oil into a clean container, and then disassemble the housing. In this case, you must try not to damage the internal parts.

Next, we need to find the inlet through which the pump draws in oil. In this hole you need to pick up and install the size of a plastic tube or piece of hose. We fasten the tube with plastic ties. Now, when we turn the jack over, it will be able to work.

Step Two The foundation

Let's make a basis on which we fix all the important nodes. Here we need a piece of thick sheet iron. At the base, we drill holes and cut the threads for screws; at the base of the jack, we also drill holes for fastening. Securely fasten the jack to the base.

Step Three Engine and gear

We’ll prepare the engine, in our case we use a starter from a scooter or a 12V motorcycle.A bicycle sprocket needs to be welded to the starter shaft, the author used a small one to obtain higher torque. First we grab the sprocket, turn on the engine and make sure that the sprocket is welded evenly.

We also need to install a driven axis, here we use a sleeve from the rear wheel of a bicycle, or you can use a sleeve where the axis with pedals is located. Similarly, we weld the sprocket, it must be large in diameter to obtain high torque. After installing the sleeve with the axis, you can install the chain. If everything is done smoothly, the chain will not fly off.

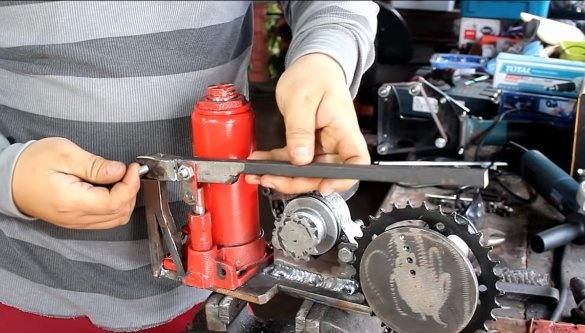

Step Four Crank and connecting rod system

We make a crank from sheet iron, it must be welded to the driven sprocket. Well, how the connecting rod and other components are made, look at the photo. The bottom line is to get reciprocating movements, as a result of which the jack pump will work. The hinges are all made primitively, with bolts and nuts.

Step Five Finishing touches and tests

In the end, it remains to assemble the frame, the author made it in advance from the channel. We install the jack and connect the wiring. The motor shaft will rotate in only one direction; when the motor is running, the jack rod will extend.

Powerful springs are responsible for the return of the jack rod to its original position.

That's all, the homemade product is ready, you can experience. The author pressed in the bearings, bent the iron pipe, the machine easily copes with the task. Of course, it would be nice to supplement the machine with a dimmer so that you can adjust the speed of the machine. In general, the home-made turned out to be successful, I hope you liked the project too. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!