The idea was to use electronic IR control module from a burnt in foreign vacuum cleaner. Do not embed it in a specific device, but make it a separate unit for use with various devices and power tools.

In this design used:

- Electronic module and remote control from a PHILIPS vacuum cleaner

- Industrial building of the company "HEGEL" for the installation of 2X network machines

- Outlet for outdoor installation

- Built-in switch

- Cable entry for 7mm wire

- Plastic trim

- Fasteners M3, M4

- Super glue

- Triac BTA12-600

- Radiator from an old video card.

Of the tools used:

- drill

- soldering iron

- MFI type "Dremel"

- Screwdriver, wire cutters, etc.

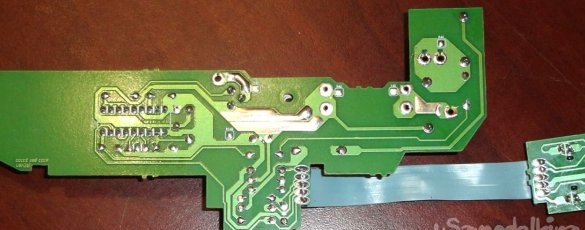

Electronic module from a PHILIPS vacuum cleaner. This module has on-off functions. and 5-step adjustment of load power up to 2.2 kW (characteristic of a vacuum cleaner).

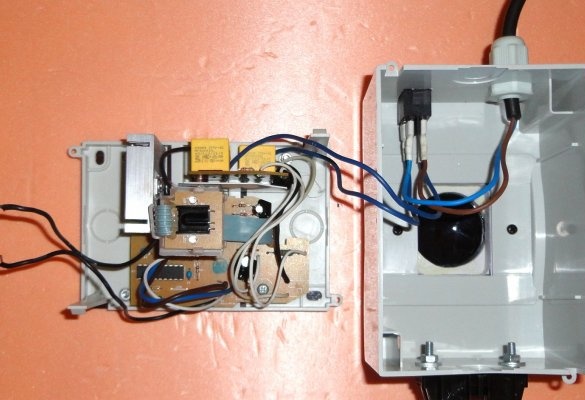

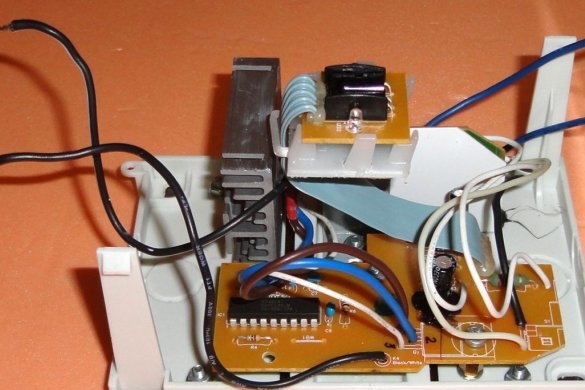

For installation in the case, because of the size, the board had to be divided into two parts in the area of the place for the native switch. And cut off the extra fields. Parts of the board are connected by a minimum amount of mounting wire. In the area of the track-free space, I made holes for fasteners. The native radiator had to be replaced. So, as it was "microscopic" and coped with its task due to its location in the air stream of the vacuum cleaner body. I put a larger radiator from an old video card from computer trash. The native triac BTA212-600 was replaced by BTA12-600 since unlike the previous one, it has an insulated heat sink. And when installed on a radiator, additional insulating gaskets are not required. The IR receiver is mounted on a plate made of a back plug from the computer case.

An additional plastic base is fixed at the bottom of the case, which covers all the extra holes in the industrial case. All the main structural details are attached to it with M3 fasteners.

Unfortunately, when installing the IR receiver, I slightly missed the height. Therefore, I had to install an additional plastic gasket, in which my native filter was glued.

An additional plastic base is fixed at the bottom of the case, which covers all the extra holes in the industrial case. All the main structural details are attached to it with M3 fasteners.

Unfortunately, when installing the IR receiver, I slightly missed the height. Therefore, I had to install an additional plastic gasket, in which my native filter was glued.

Extension cord assembly.

The remote control is powered by two AAA batteries. The remote control has 4 multidirectional emitting IR diodes.Therefore, due to reflections, practically all places and angles in the room are covered.

Due to the fact that this device uses a pulse method of power control, its use to control lighting devices will be problematic. On incandescent lamps there will be a strong flashing.

I have this extension cord so far perfectly used with old models vacuum cleaners and perfectly controls the outdoor fan.

If anyone has ideas on how to use this device, I will be glad to share it !!!

I hope that all the features of the design are visible in the submitted photos.

If you need additional information, write to the post office, I will try to be sure to answer.

Feedback, suggestions and comments are very welcome.

August 2019