Many of you are engaged in carpentry, and are faced with the need for precision drilling.

In this article, Jester, author of the YouTube channel Made by Jester, tells you how he made a simple but accurate conductor for drilling holes in the corners of workpieces.

Materials

- sheet plywood

- PVA glue.

Instruments, used by the author.

—

—

- A circular saw

- Drilling machine

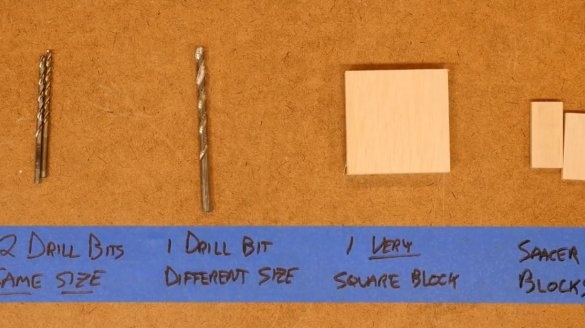

- Drills for wood

- A pencil, a square, a ruler.

Manufacturing process.

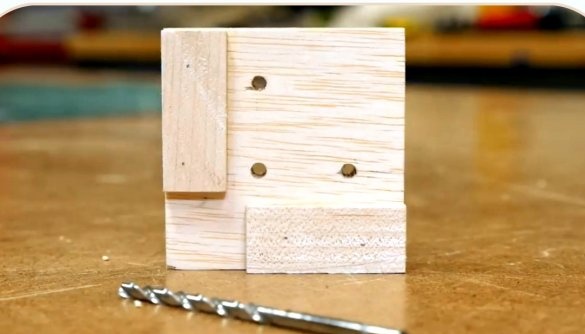

First of all, the master cuts the square base for the conductor from thick sheet plywood.

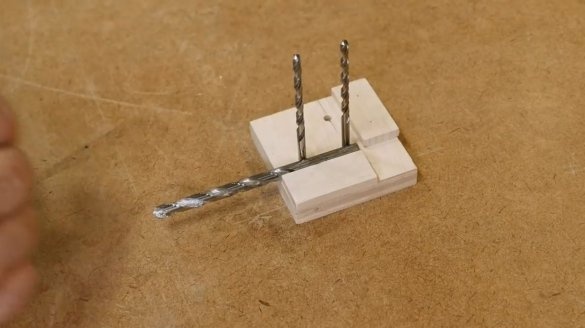

Then two rectangles are cut out, they will serve as stops. It will also require two identical drills, and one thicker.

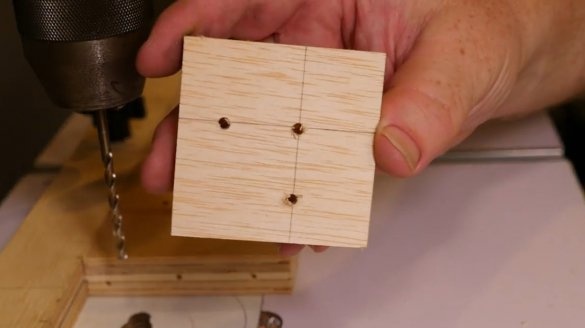

On the conductor, two lines are marked at a right angle.

Now the first hole is drilled, the workpiece unfolds, and the emphasis moves. Next, two more holes are drilled.

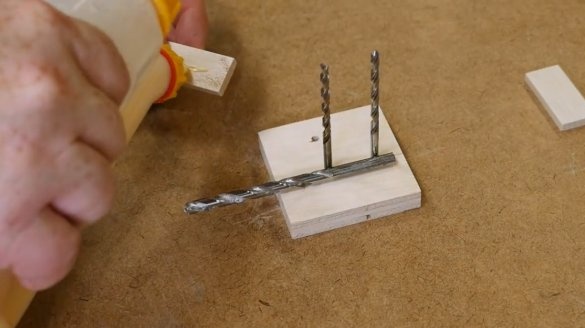

Inserts two drills into a pair of holes, applies a thick drill to them, glues the first stop, additionally fixes it with a neiler.

The second emphasis is also fixed.

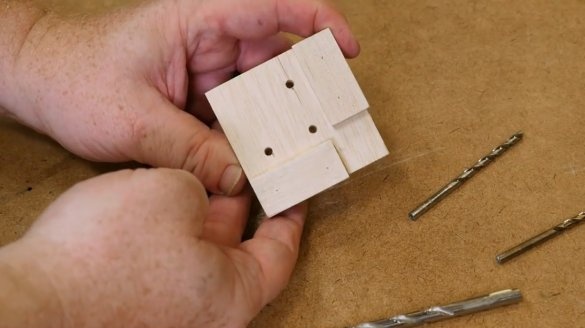

The locking blocks protrude slightly beyond the edge of the base, they must be cut flush with it.

That's all, the conductor is ready, now on the workpieces you can easily and accurately drill holes at the corners. Also in terms of finalizing this fixtures, steel tubes can be driven into the holes so that the edges of the holes last for a long time.

I thank the author for a simple but useful tool for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.