From the article below you will learn how to make a ring of wood. The following description and instructions are taken from the Matthias Wandel YouTube channel.

This homemade - this is just an experiment of a master in the manufacture of wooden rings - such that people carry on their fingers ...

Necessary materials and tools used by the author:

- pantograph with a manual router;

- a variety of solid wood;

- band-saw;

- bench-top belt sander;

- screwdriver;

- sandpaper with a grit of 600 units;

- abrasive paper;

- paper towel;

- a pencil;

Earlier, the master made a ring by drilling a hole in a tree and cutting it out with a spiral saw. But for proper finger pressure, the size should be wider no more than half a millimeter. It is not always possible to choose a drill of the right diameter.

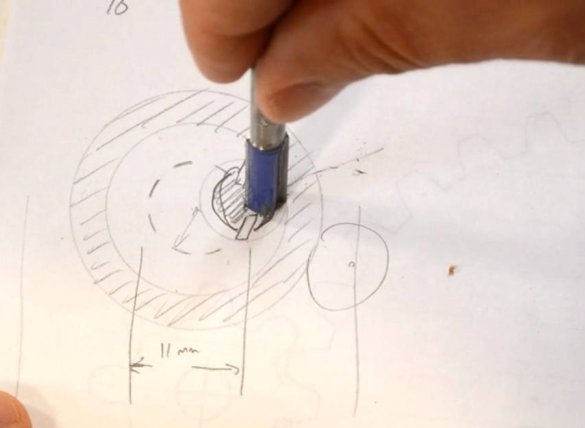

The master came up with the idea of using the pantograph of his router to route holes of any size, and then he decided that since he would use the router for an internal hole, he could cut the ring from the outside in the same way.

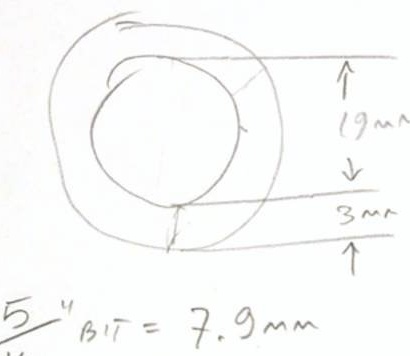

For the inside of the router, a sweep around the circle is required, that is, the diameter of the milling bit is less than the desired internal diameter, and outside the diameter of the milling bit. It required an inner diameter of 19 mm and a ring thickness of 3 mm, so that the outer diameter was 25 mm. This was practiced on a router moving in a circle with a diameter of 11 mm and 33 mm.

The master set the milling pantograph to decrease by 1: 3, so before reducing it is necessary to trace circles with a diameter of 33 mm and 99 mm or radii of 16.5 and 49.5 mm.

An attempt to make the first sample of maple. Inside the master made a cut counterclockwise, and outside clockwise. Thus, the milling machine always cuts into a tree, this minimizes the accumulation of chips.

The first workpiece is ready ...

Now it remains to cut it off with a band saw.

Fitting. With a thickness of 3 mm, the ring is terribly clumsy.

Milling another workpiece, this time with a wall thickness of 2 mm, and cutting from exotic hardwood.

The second ring is cut out. The master decided to find out how hard it would be to break it. He could break it by pressing on it with just his fingers, but it was surprisingly strong.

Routing was relatively quick, so the master instantly made another ring.

The master wanted to tap the outer edges of the ring. This is best done with a grinder.But this is difficult to do consistently and freely, so he made a tool to hold the ring in his hands.

He made this instrument with the help of a pantograph, just as he did the rings.

The bevels are ground.

The next task: to polish the ring from the inside.

The grinder will be very difficult to use, and the grain size will probably be too coarse. In addition, the master does not have a spindle grinder.

A four-jaw lathe chuck can be used to rotate the ring while grinding the inner surface. However, the master does not have such a cartridge, so he decided to improvise from wood.

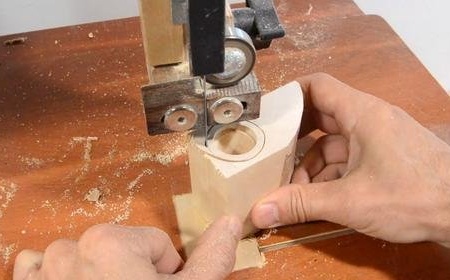

He started by drilling a hole a little more than a ring, and inside it a much deeper hole. Then this product was cut on a tape machine ...

... then I had to cut something like a collet, and also slightly make it thinner to make the collet more flexible. If the walls were made thinner at first, this step would not be needed.

Ring holder. View from above.

Elastic bands around the holder provide uniform pressure. The rotation of the holder with a drill allowed to grind the inner surface with sandpaper.

For fine grinding the outer surface of the ring, the master made a mandrel on a table saw. The mandrel was a piece of 19 mm. cylinder.

The photo shows how the master polishes the ring using 600 grit sandpaper ...

... then the ring is ground with abrasive paper.

And finally, the ring is rubbed with a paper towel to give it more shine.

As a result, the master got these two rings. Right just polished, left with varnish. They differ from those shown in the figures at the beginning of the article. First, the master polished too thinly and it broke rather quickly. So, as an experiment, the master made another one, made of dark wood, and a little wider and thicker. But after polishing, it turned out to be difficult to remove from the "ring holder" and it also cracked.

So making wooden rings is more exotic. Production does not take much time, but a wooden ring does not live as long as a metal ring.

If you liked the author’s homemade, then try to repeat and make.

Thank you for attention.

See you soon!