I welcome all fans to craft, I propose to consider instructions for remaking the grinder in brush grinder. Auto decided to make it possible to make the installation of nozzles from a brush grinder on the grinder. The nozzle was used with a width of 100 mm, which allows you to quickly and efficiently clean sheet metal from rust and paint, the same applies to pipes and other parts. Each sheet of such a nozzle consists of sandpaper, in fact, it is an analogue of a petal nozzle, only soft and even more productive. Grain sandpaper is diverse.

Dangerously!

Please note that the brush head is not designed for high speeds. brush grinder revolutions in the region of 3000 rpm, and the grinder in the region of 11000 revolutions. The grinder must have a speed control, or turn on the grinder through a dimmer. One way or another, if you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- nozzle from brush grinder 100 mm wide;

- round timber;

- cotter pin, screw, nut;

- steel plates;

- sheet steel for the shield.

Tool List:

- lathe;

- grinder;

- drill;

- rivet gun;

- vise;

- milling machine.

Manufacturing process homemade:

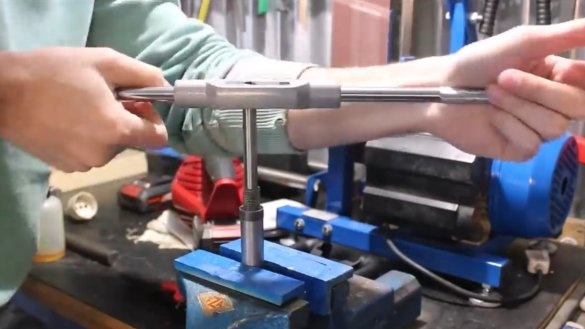

Step one. Turn the axis

Under the brush nozzle, the author had to carve a new axis, a round log was used for this. At one end of the axis, drill a hole and cut the thread so that the axis can be screwed onto the Bulgarian shaft. In the axis, a seat is bored under the expanding part of the shaft of the grinder, this ensures alignment.

There is also a hole at the other end of the shaft and a thread for the mounting screw is cut. To prevent the brush from spinning, the author milled the grooves and inserted a cotter pin. Actually, the manufacture of the axis was the hardest part of homemade work.

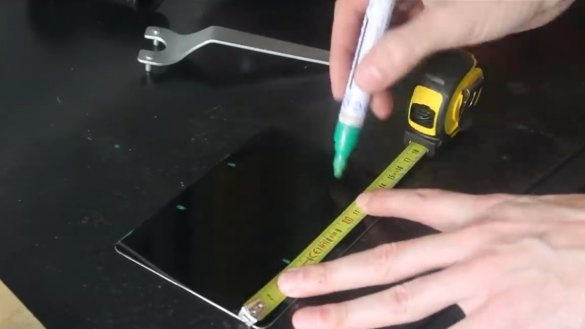

Step Two Shield

Be sure to make a protective shield for the tool, it will protect not only from dirt, but also from larger pieces that can get into your face and eyes. For the shield we assemble a simple mount from steel plates.The shield is bent from sheet steel, it is attached to the plate with a rivet gun, simply and quickly.

Step Three Test

The homemade product is ready, turn on the revolutions acceptable for the selected nozzle and try to work. The author quickly cleans a piece of sheet steel from rust, the nozzle easily copes with paint. Pipes can also be cleaned with the tool, including round ones, since the brush will envelop them, which hard nozzles cannot do.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!