A similar cabinet can be bought at a furniture store, however, quality furnituremade in good conscience from reliable materials will cost a lot. It is quite possible to make a similar stand do it yourself, just the presence of basic tools that are in the arsenal of almost any home master. Missing tools can be borrowed or rented.

What is required:

Before you begin, you need to stock up:

- metal pipes with a square cross-section of different sizes;

- plywood, boards,

- varnish, black paint in a spray can,

You will also need:

- clamps, vices,

- saw for metal,

- welder, drilling machine,

- Sander,

- tape measure, awl, metal brush.

Stage 1.

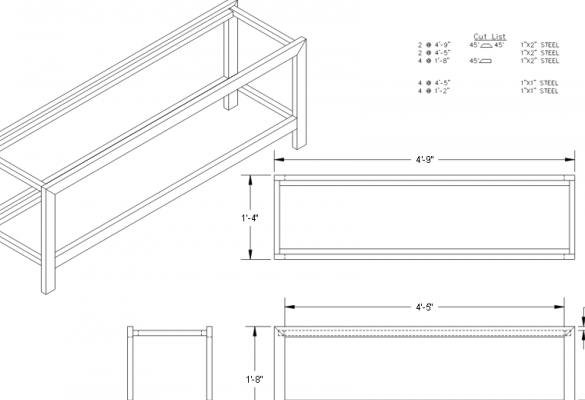

Estimate the dimensions of the cabinet, based on the size of the TV. Make a drawing of the product.

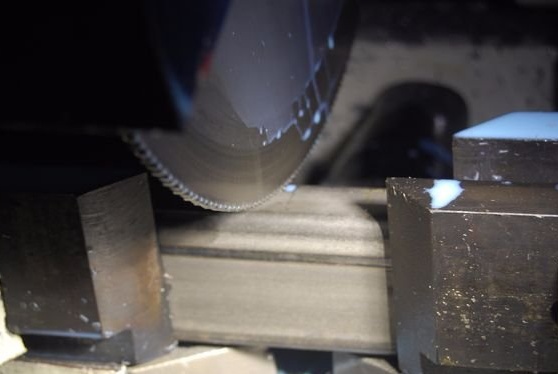

Stage 2. It is necessary to cut pipes into segments that will become elements of the future table. Before cutting, marking is applied, it is more convenient to do this using a tape measure and an awl. Apply marking by notching with an awl for metal.

The frame is two rectangular walls with legs. In this case, square pipes, gauge 16 are used. After cutting and trying on the parts, you can start welding.

The crossbar, which will be at the top, is cut off at an angle of 45 degrees, and below at an angle of 90 degrees, while the pipe is welded so that there are legs. The height is arbitrary, there will be a shelf. In the process of manufacturing this bedside table, the height of the legs was determined at 15 cm. After checking the accuracy of the cut, duplicate the second frame.

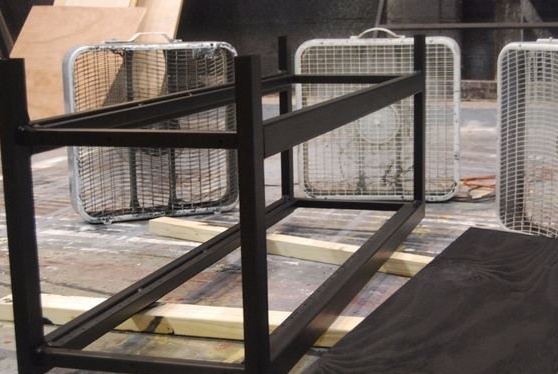

Stage 3. Having welded the frame, we clean the seams. Internal cleaning can be rough, with a saw, thorough grinding is required on the outside, the surface should be as even as possible.

Stage 4. The side frames are connected in a single structure with two additional rectangular parts made of pipes. Sources are required smaller, the rectangle in length will be shorter than the side shelves.

After cutting the side pipes of the frame, drill holes so that the distances between them are equal.For an exact match, clamp both pipes from the same frame in a vice at once, make a hole with a drilling device. The distance between the holes depends on the size of the boards that you

Having made holes for fasteners, sand the product using a grinding machine.

Step 5. Rectangular frames are welded from the pipes. On each side, weld the metal parts of the nightstand, clean the seams.

Stage 6. The frame is prepared for painting, processed with a metal brush, and then painted with a spray can. The finished product is dried.

Stage 7. The lower shelf is made of their plywood. The sections are cleaned of roughness, the shelf is painted to match the color of the frame. You can apply the paint twice.

Stage 8.

To make a countertop, boards are cut, the same in length, the edges are processed. The length of the boards corresponds to the size of the small frame. Boards can be coated with stain or varnish. Paint is not suitable, since it is important to show the difference in textures.

Stage 9. The boards are fixed on the frame, forming a countertop and a shelf under it. Two more boards are fixed on the sides of the shelf, this gives it a complete, stylish look.

Designer TV stand is ready!