This spot welder can be used to weld 18650 Li-ion batteries. To do this, you need a 7-12V power supply (12V recommended), which is used as a battery from a 12V car. Typically, one 45A \ hour battery is enough to provide enough current to get good welds. Nickel strips 0.15mm thick are welded. For thicker nickel strips, you may need a more powerful battery or you can connect two in parallel.

How the device works

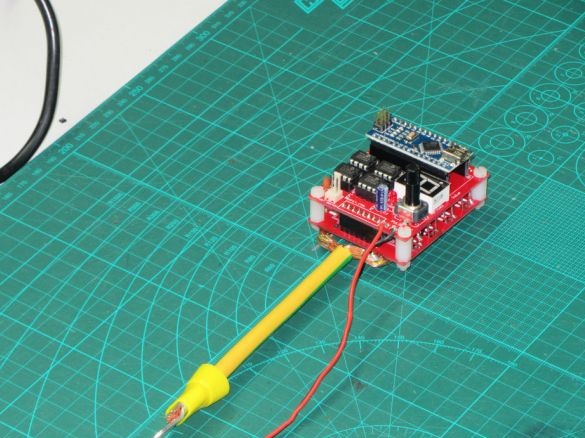

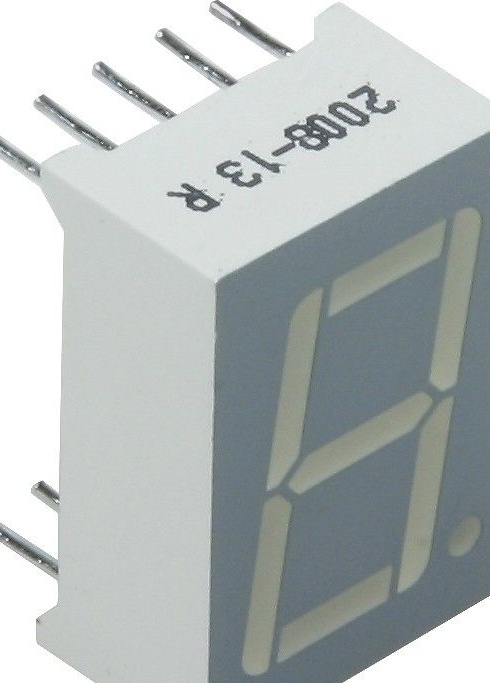

The device generates a double pulse. The first impulse is 1/8 of the time of the second. The duration of the second pulse is adjusted using a potentiometer and displayed on the screen in milliseconds, so that you can fine tune the time. Its duration is adjustable in the range from 1 ... 20 milliseconds. The video shows a more detailed assembly process of the welding device.

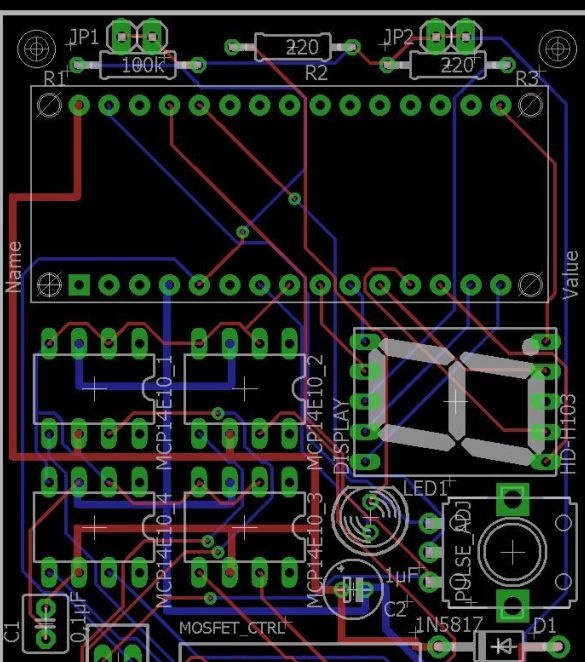

All printed circuit boards in the archive in the format of the program “Eagle”.

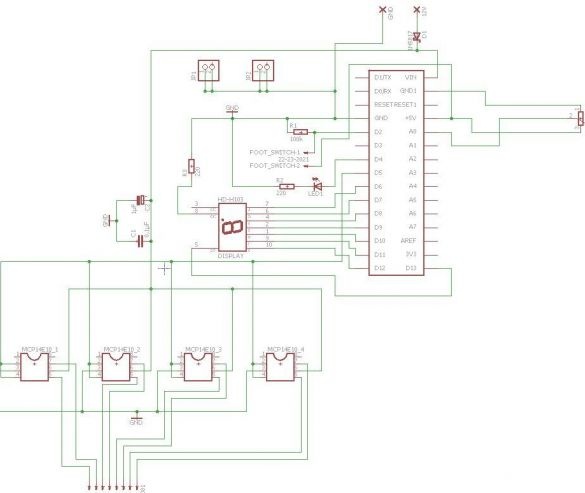

Schematic diagram of the device

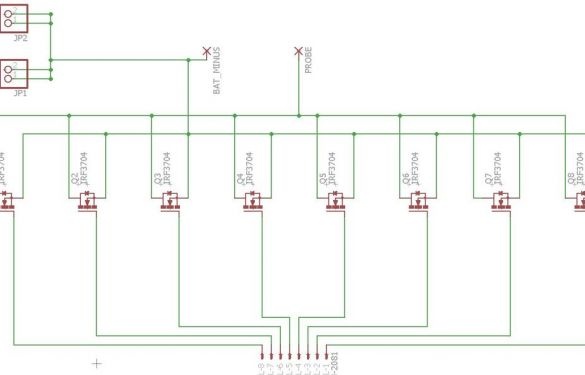

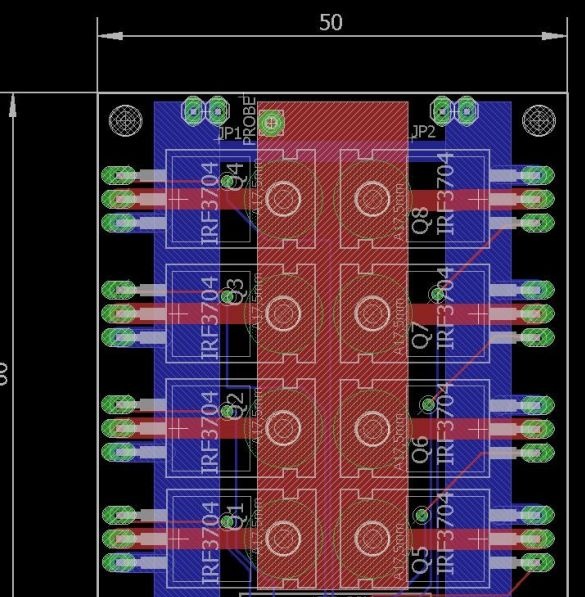

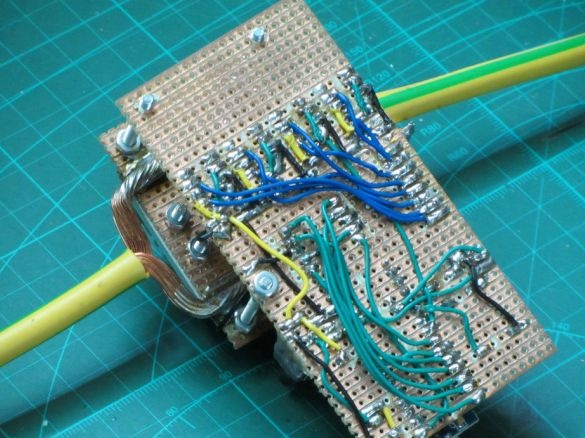

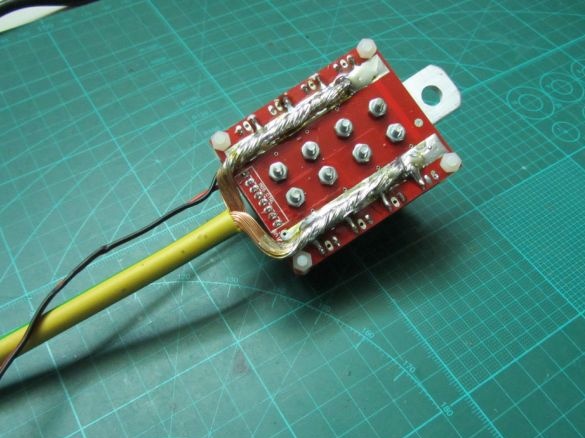

Power Key Circuit Board

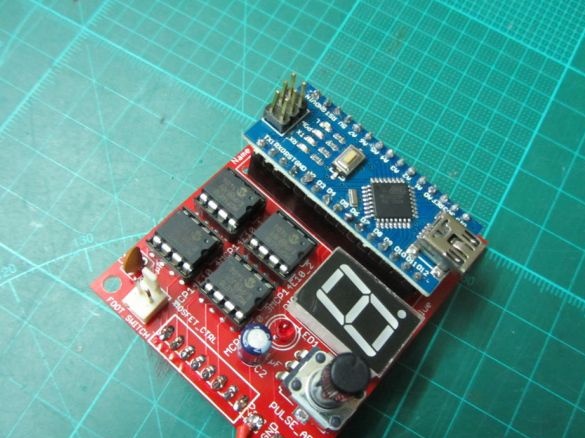

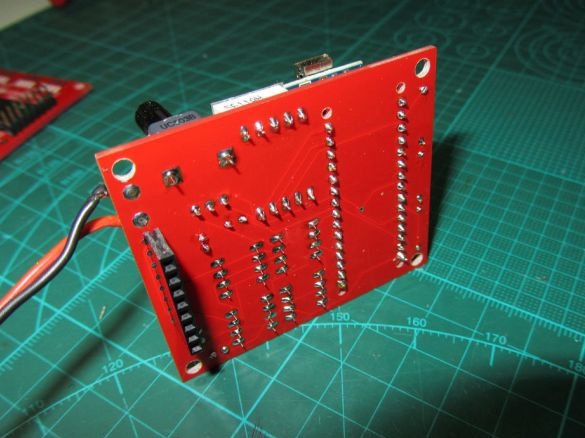

The circuit board of the device itself

You can download the program

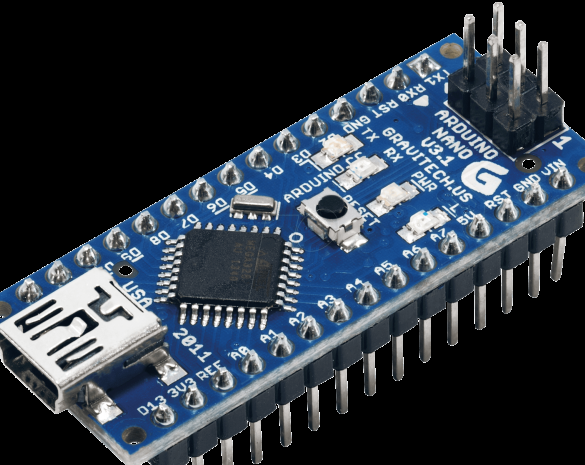

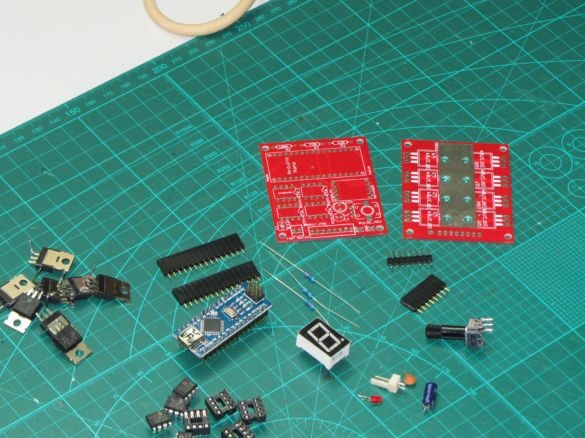

In the device, to facilitate assembly, the author does not use parts in SMD cases. Start assembling with small parts.

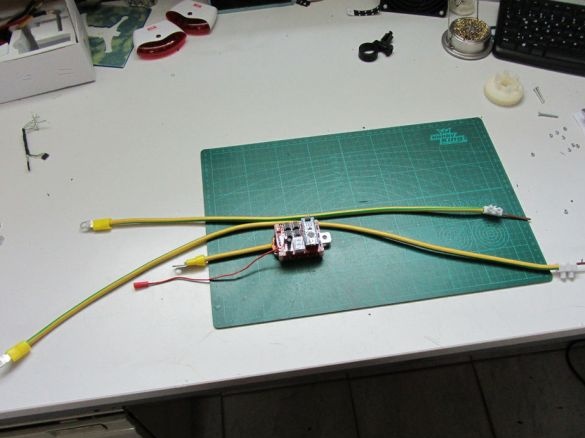

Welding nozzles are made of a copper core with a cross section of 10 sq. Mm,

Connecting cable - copper, stranded cross-section of 16 sq.cm.

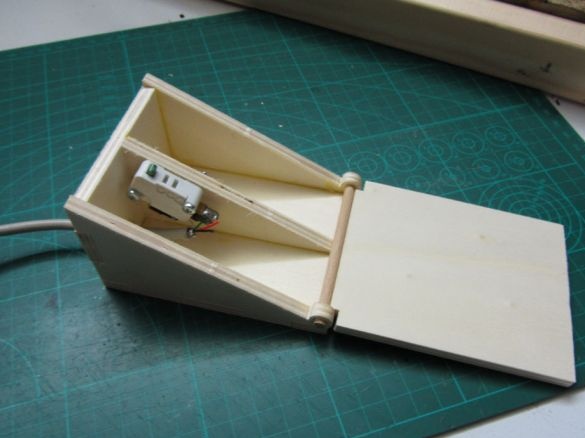

To work with the welding machine, two hands are needed to hold the parts to be welded together. It is necessary to make a foot switch. The author made it from a small wooden box.

What is needed for assembly:

Transistors -, on Aliexpress for $ 6 for 5 pcs

Drivers for these transistors - MCP 14E10-E / P (4 pcs) on Aliexpress did not find,

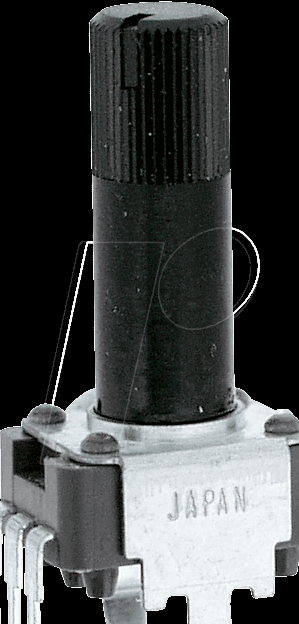

Vertical Variable Resistor RK09K113-LIN50K (50K 1pc)

Not necessarily just such a resistor, you can use any 50k variable, but then it will have to be moved outside the printed circuit board.

(1 PC)

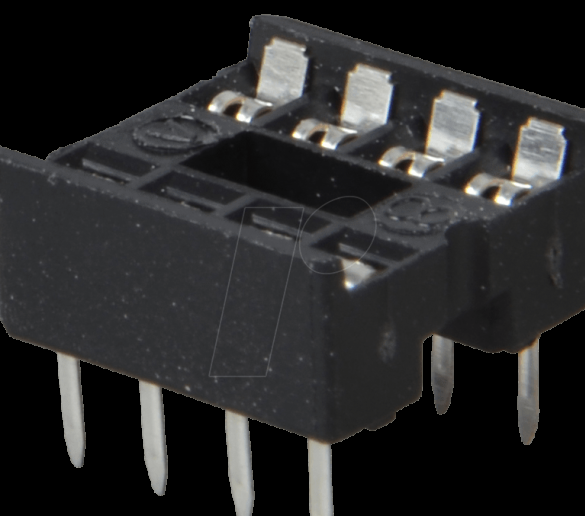

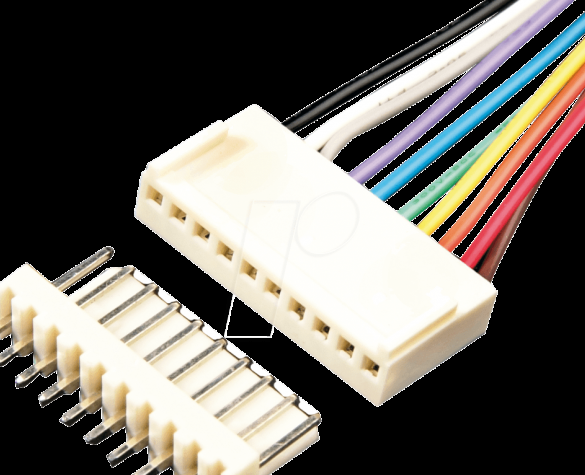

Sockets for drivers (4 pcs)

Or such

Single diode 1N5817

One 1mkF / 63v electrolytic capacitor, one 100pF ceramic capacitor, two 221 Ohm and 100K resistors, one 5mm green LED.

Aluminum plate with dimensions 16x70x5 mm

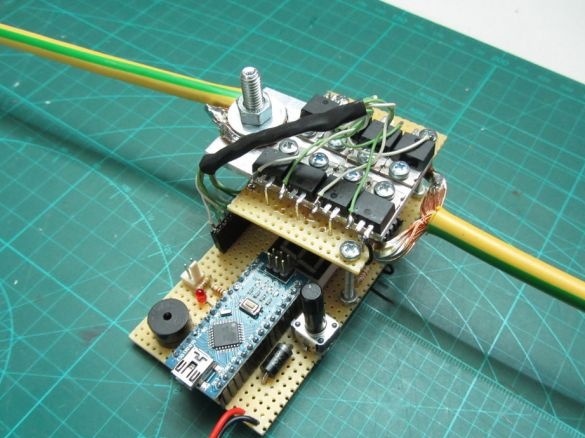

Photos of the finished device in two versions - on the breadboard and on the board ordered on the Internet

In the archives, printed circuit boards and firmware for the welder