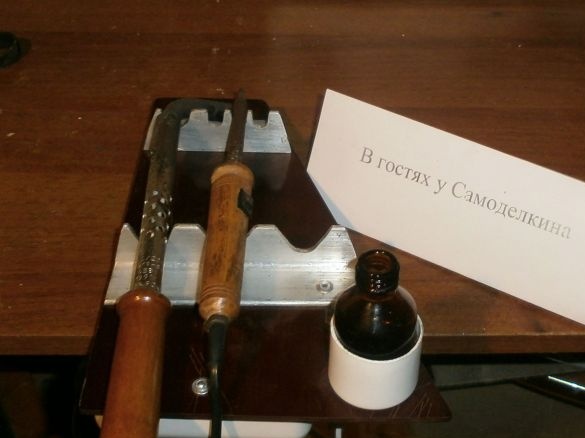

I don’t really like to solder, I do it very irregularly, and therefore I never looked at fashionable soldering stations. And with this kind of work, I always lacked a soldering iron stand, especially when two were needed. Powerful, bigger for rough soldering, and small for fine. But there was nothing like this on sale, which means that you need to do it yourself. I hope my experience is useful to someone.

So, to make a stand for soldering irons, you will need:

• a piece of PCB, 20 by 25 cm and a thickness of 3 mm;

• aluminum (easier to handle) corner, about 40 cm long, and a shelf of 30 mm;

• double external socket and cable with plug;

• 10 rivets with a diameter of 4.8 and a length of 14 (16 possible, not important) mm;

• the same number of M5 washers;

• and a plastic jar from under some kind of medicine. It is important that its inner diameter is slightly larger than the acid bottle.

From the tools:

• hacksaw;

• various forms of files;

• drill with a drill of 5 mm;

• core with a hammer;

• screwdriver;

• knife;

• and riveting gun. Although you can replace it with rivets with screws with nuts, the essence and technology of this does not change.

That's all, let's get started.

We cut the PCB sheet at an angle (for beauty),

And we divide the corner into three parts, and two - we cut diagonally. It is useless to size here (I didn’t use the ruler at all), everything is exclusively “in place”. We drill them and make appropriate selections for the thickness of the handle and the tip of the soldering iron.

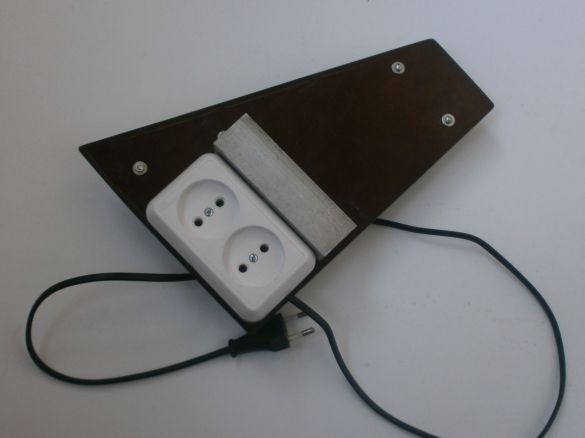

In the cover of the outlet, we drill three holes (two would be enough), and fasten with rivets. And so that they do not crush the plastic and textolite when pulling, we put the washers in place: such a simple option was suggested to me by experienced auto makers.

Now we attach two pieces of the corner under the soldering irons, the base for the bottle with acid,

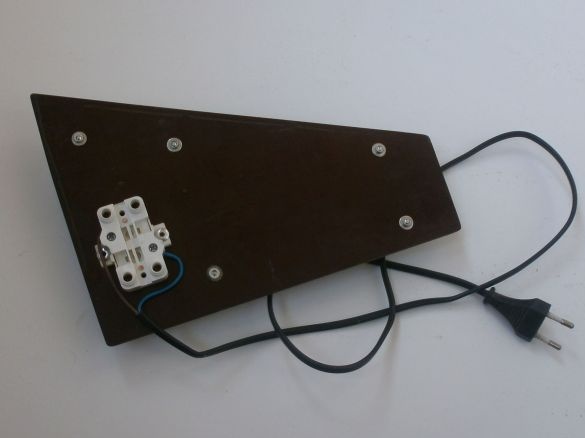

And on the back, the inside of the outlet. We fix the electric wire in it,

And close the lid.

It would seem that the soldering iron stand is ready. but the first test in practice showed that she is staggering quite strongly, and she strives to fall. And this is with hot soldering irons. It’s not at all a matter, I reasoned soberly, and began to think about how to modernize my very good idea.

The idea came by itself when I came across a small clamp from an ancient table lamp. And I did not even have to come up with a mount, since it had a metric thread for mounting the lamp legs.

He removed a corner from the box. Pliers and a drill with a diameter of 8 mm to help you, they also drilled a single hole for a clamp, and secured it with a screw.

Now that's all, the soldering iron stand is ready.

And from personal experience I’ll say that using it in work is very, very convenient.