You can make reliable, high-quality and durable housings for various types of electronics do it yourself. This, of course, will require some skills, efforts, but it will help to significantly save money (factory buildings made of aluminum and even ordinary plastic structures are very expensive).

To make a home-made analogue of the housing for electronics, take a 40-centimeter section of a profile galvanized pipe of rectangular cross section 100x50 (such dimensions will effectively dissipate heat). It is desirable that the wall thickness of the pipe is not more than 3 mm. For small electronics, the dimensions used should be slightly smaller - 40x20, and the pipe wall thickness 2 mm. You can purchase such pipes in specialized construction stores. You will need a minimum of tools - only a drill or screwdriver (for drilling holes), as well as a grinder (directly to cut the pipe).

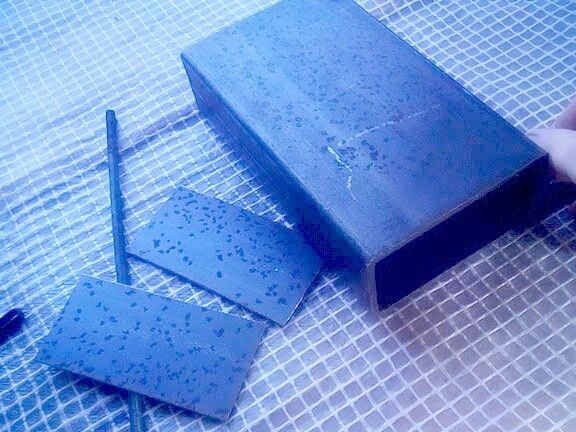

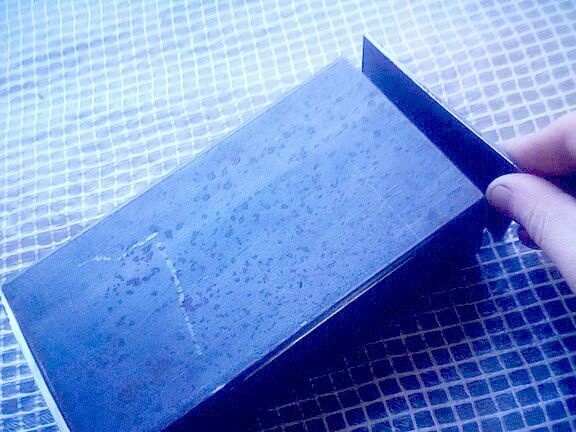

Cut 18 cm from the profile pipe - this will be the body itself. Its side walls, also obtained by cutting from the pipe, must be fastened with 4 studs passing through the corners along the length of the entire body. In this case, they will not interfere with the placement inside all the necessary parts. To ensure an optimal clearance for quick cooling, cut a 20/20 mm profile so that you get two corners in the shape of the letter L. They need to be screwed on the sides to get an excellent wall mount.

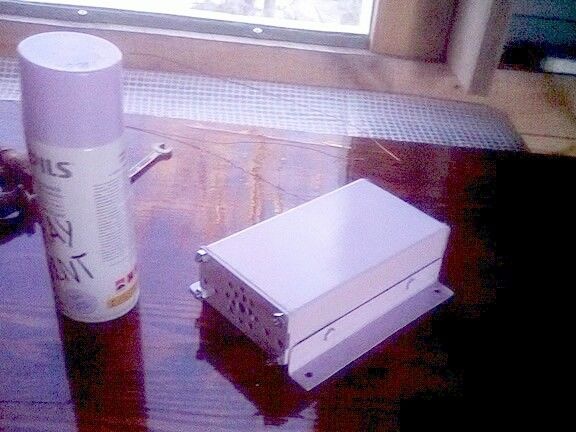

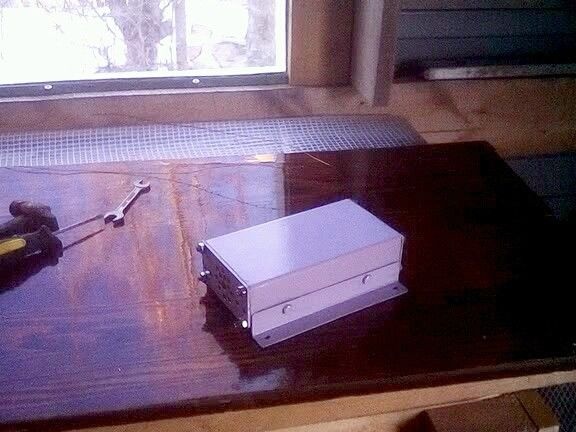

A home-made metal case with sufficient thermal conductivity, which, due to its considerable weight, is more suitable for stationary use, is ready. It remains only to give it an attractive appearance, i.e. to cover with spray paint, after priming and degreasing the surface, so that the paint lies more evenly and lasts longer.