So the summer ended, ahead of autumn, and after it pretty soon the cold. It's time for motorists to make sure that their auto It worked flawlessly in winter, and the ride was quite comfortable. Of course, the first problem that comes with cooling is freezing. Previously, we already examined instructions on how to make steering wheel heating, heating wipers, antifreeze and other components of a car, but today we will focus on finalizing elements such as rear-view mirrors.

When driving in frost, and just in wet weather, frost or ice crust forms on the mirrors. You can deal with this problem by heating the mirrors. How to implement this at minimal cost, consider below.

Materials and tools for homemade:

- nichrome wire (can be found in various heating elements or buy);

- industrial hair dryer (in extreme cases, a household one is also suitable);

- Double-sided tape;

- multimeter;

- hot glue;

- soldering iron;

- wires and other little things.

The process of finalizing mirrors:

Step one. Parsing mirrors

First, the mirror must be disassembled and the glass removed from it. If there are plastic frames or other elements in the mirror, it is advisable to heat them with an industrial hairdryer before disassembling, otherwise there is a risk of breaking. As a result, everything should turn out approximately as in the photo.

Step Two Installation of a heating element

First of all, carefully remove the old tape from the mirror. Here you need to be careful, otherwise you can easily damage the amalgam, in which case the mirror will turn into an ordinary glass. After the surface is cleaned, double-sided tape is glued to it.

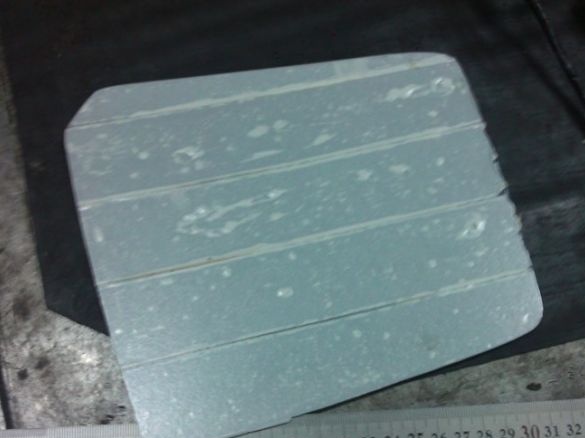

Now the protective film of the second side of the adhesive tape can be removed. Nichrome wire can be installed on the prepared adhesive layer. The final resistance of the spiral in the author is within 8.5 Ohms, and the current consumption is 1.5 A. The thickness of the wire should be within 0.2-0.4 mm, a thicker wire can not be taken.

Among other things, the author connected the circuit in parallel, as a result, the resistance drops and the heating circuit warms up more.

As a result, the installed spiral is closed on top with tape.

Step Three The final stage of assembly

After that, the glass can be glued to the frame, for this it must first be prepared by cleaning it from dirt and degreasing it. Then you can again remove the protective layer of adhesive tape and install the glass in the frame.

On the back of the mirror, the author made contacts for connection. It’s best to solder them.To fix the contacts, they must be fixed with thick glue (for example, hot glue, epoxy, etc.).

That's all, now the system can be connected to the on-board network. For these purposes, you can display a separate button, or, as the author did, connect to the rear mirror heating system. The polarity in this case does not matter.