In this article we will consider the next model wood lathe. The master uses an electric drill in his machine as a drive.

Tools and materials:

-Bearings;

- Bushings;

-Screwdriver;

-;

-;

- Clamps;

-;

-;

-Bolts with nuts;

-Glue;

-Marker;

-Pneumatic gun;

-Gon;

-Drill;

-A screwdriver;

-Adjustable wrench;

-Paper;

-Bit with a head;

-Nuts;

- Locking furniture nut;

-Plywood;

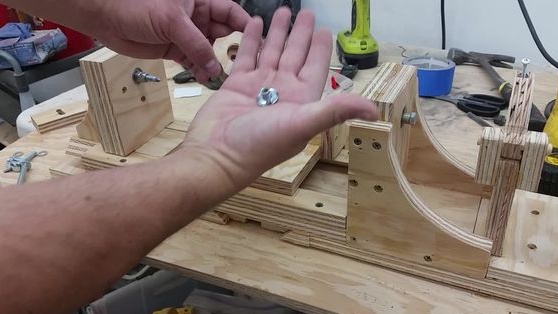

Step one: bearings and bushings

A good master does not lose anything, even old roller skates can serve as a source for future homemade. Having disassembled the roller skates, the master “obtained” bearings and bushings.

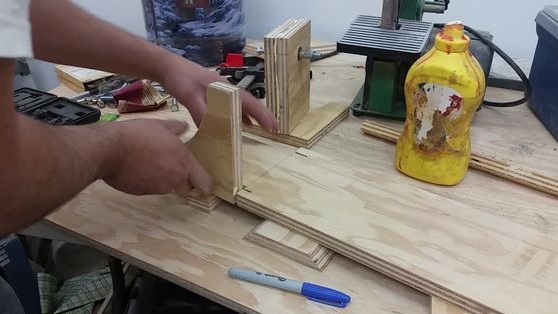

Step two: blanks of the front and rear headstock

Almost the entire machine is made of plywood. For the front and rear headstock, the master cut four rectangles from plywood. Glued them two together. Made bearing seats.

Step Two: Foundation

All parts of the machine are fixed on the base. The base is a rectangle of plywood with a narrowed front.

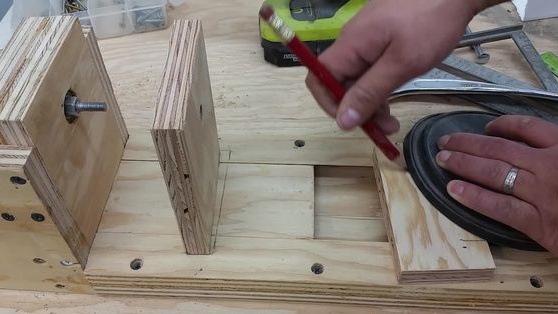

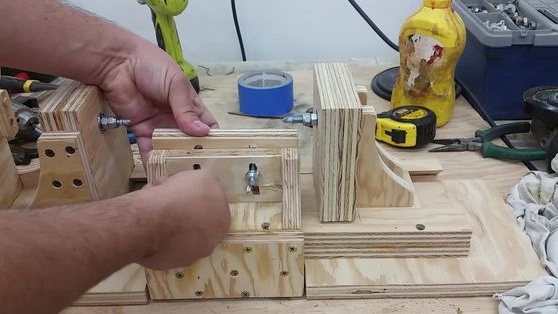

Step Three: Build the Headstock

Installs bearings and bushings between them.

The center is a bolt with nuts screwed on, behind and in front. A smaller thread is cut into the front of the bolt. A persistent furniture nut will be wound on it. Bottom and sides, first glues, and then nails, stops. Secures the headstock to the base.

Step Four: Guide

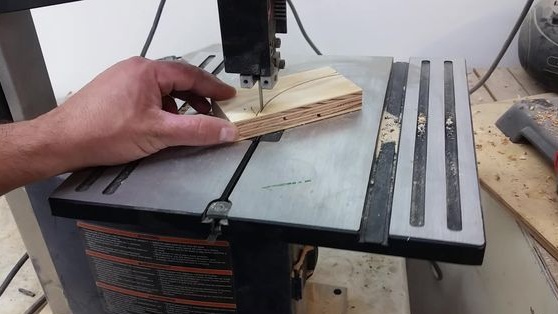

For the guide, the master cut out two slats with an angle of 45about on the one hand and a rectangle (moving part) with lateral notches under 45about.

Secured one rail on the bed. I wrapped the movable part with paper and set it in place. Secured the second rail. Removed the paper. Thanks to the paper, a gap was obtained between the parts of the guide.

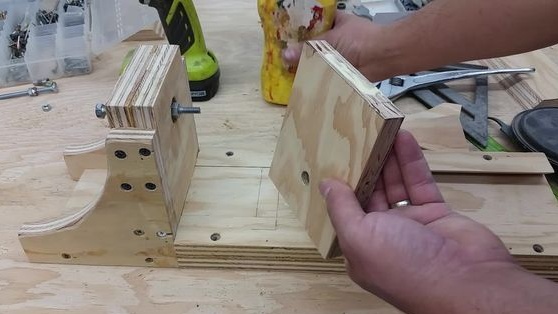

Step Five: tailstock

The tailstock is assembled similarly to the front. After assembling the headstock, the master fixes it on the moving part.

Step Six: Handyman

The handyman of the master is adjustable across and up. To ensure mobility will be the same guide system fixed from the bottom of the base.

The height is adjustable using vertical grooves.

Seventh step: mount the drill

Cuts and sets clamps for a drill.

The machine is ready. It remains to fix the furniture nut with an emphasis at the ends of the workpiece and test the machine.

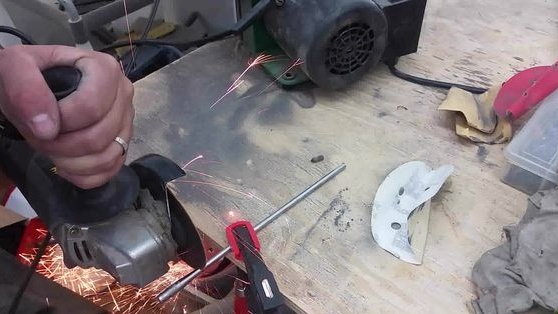

For the manufacture of parts of the writing pen, the master made a mandrel from a steel rod.

Here is the pen.

All information on the manufacture of a lathe can be seen in the video.