In this article, the author of the YouTube channel "jisaku-kobo" will tell you how to make very useful out of a regular laser module or pointer device for home and workshop.

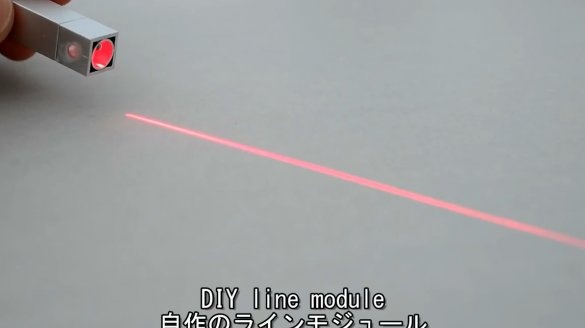

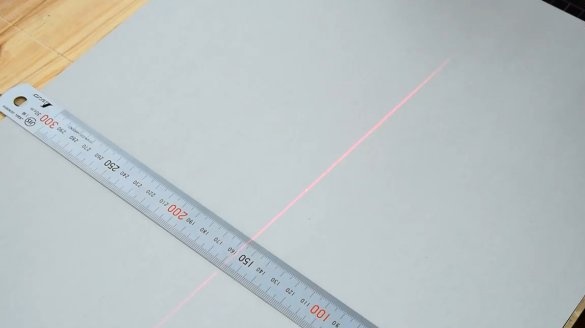

This simple design will make a point laser linear.

With its help, it will be possible to make linear pointers for various machines, which will greatly facilitate the work.

Materials

- Aluminum tube with an external diameter of 8 mm and a wall thickness of 1 mm

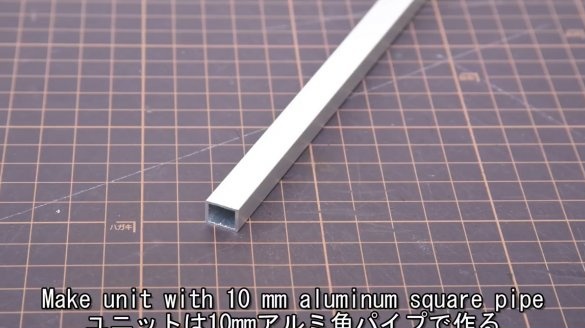

- Profile aluminum pipe 10X10 mm, wall thickness 1 mm

- Laser module

- Plastic bolts

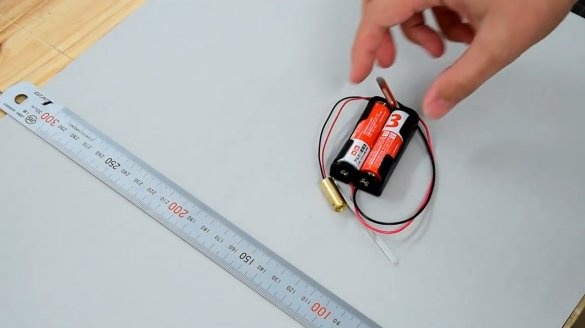

- Holder for two finger batteries

- Heat shrink tube, solder

- Two-component epoxy resin

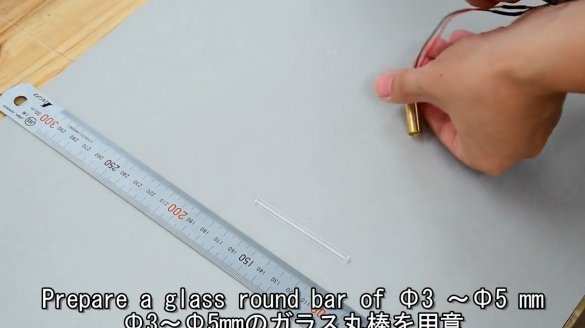

- Glass round bar with a diameter of 3-5 mm

- masking tape

- Two AA batteries.

Instruments, used by the author.

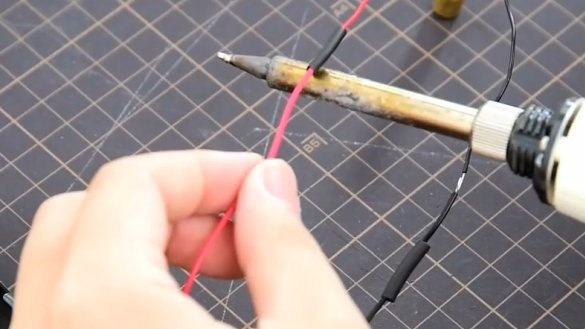

- soldering iron

- A small circular saw, or a hacksaw for metal

- clamp

- Flat and Phillips screwdrivers

- Drilling machine

- Square

- tap

- Diamond file.

Manufacturing process.

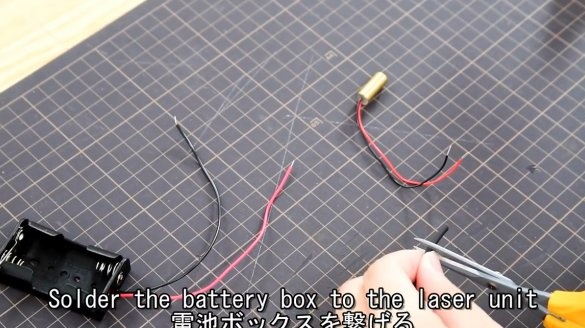

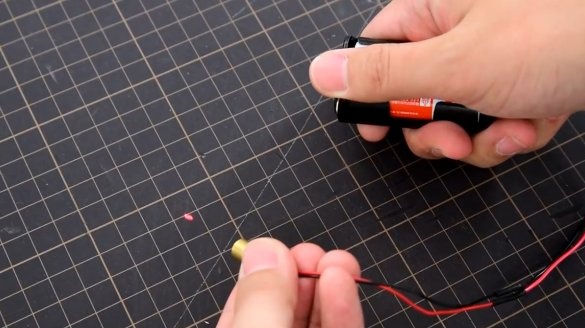

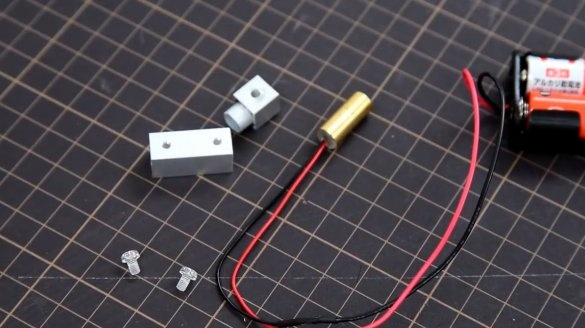

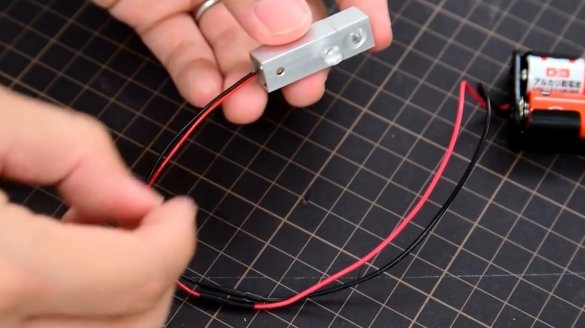

So, the author acquired a laser module with a wavelength of 580 nm, and a battery compartment.

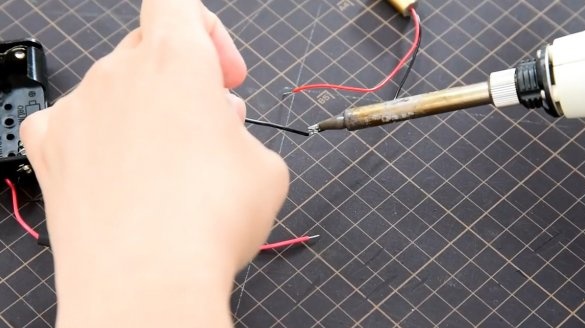

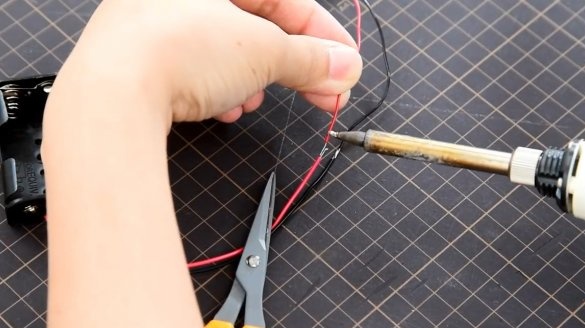

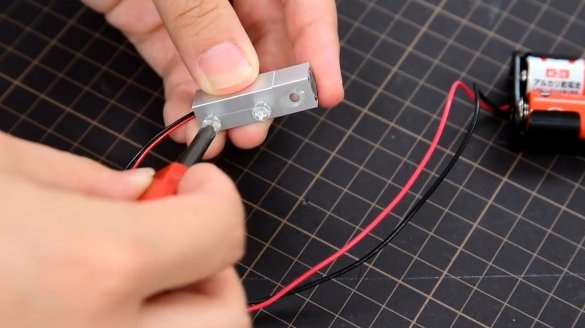

Then he cut the heat shrink tube and put it on the wires. Then he disappeared the joints, moved the tubes on them, and heated them for shrinkage.

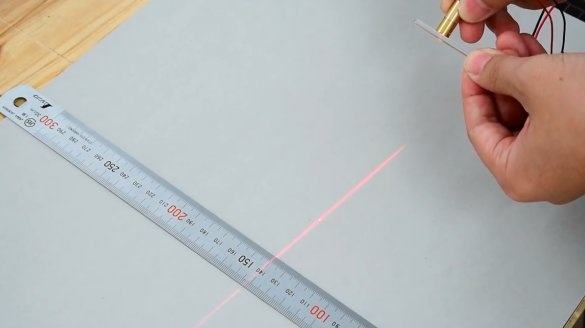

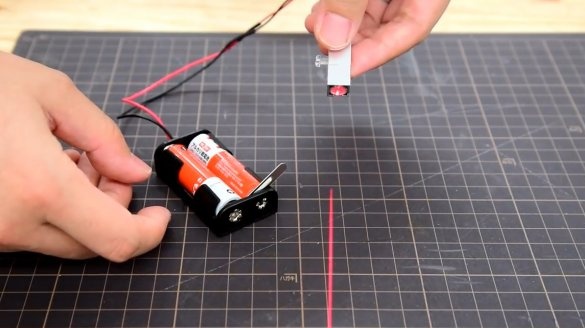

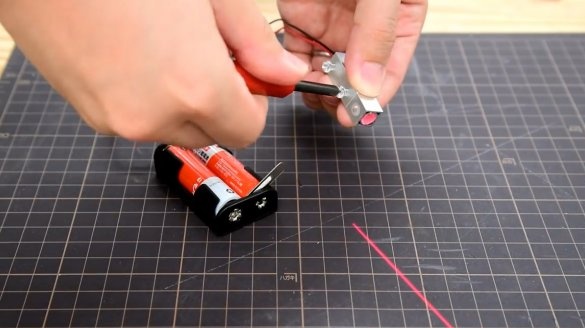

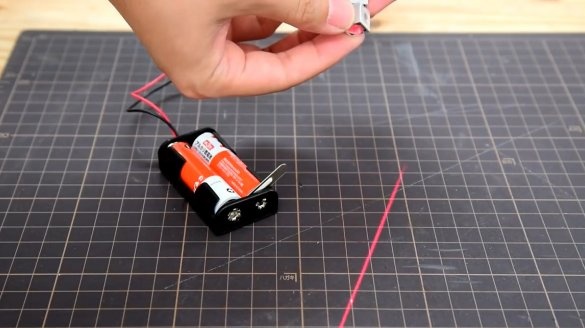

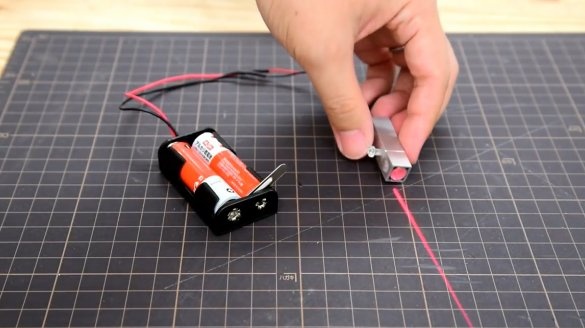

I installed the batteries and turned on the laser. As you can see, the focal length of the module is about 9 cm.

Turning the adjusting screw, the author changes the focal length to 4 cm.

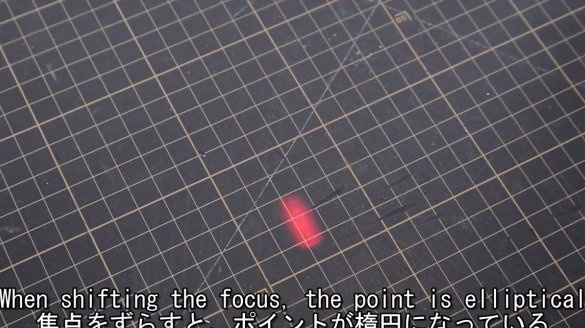

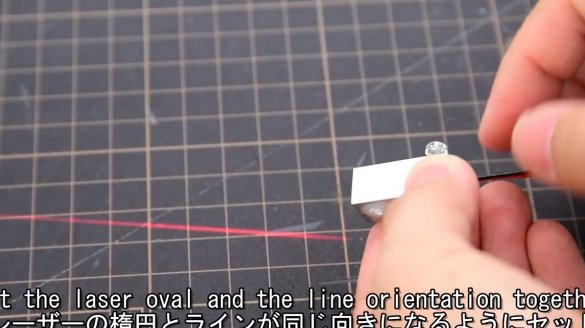

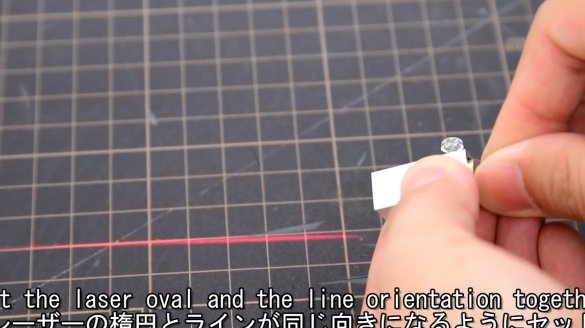

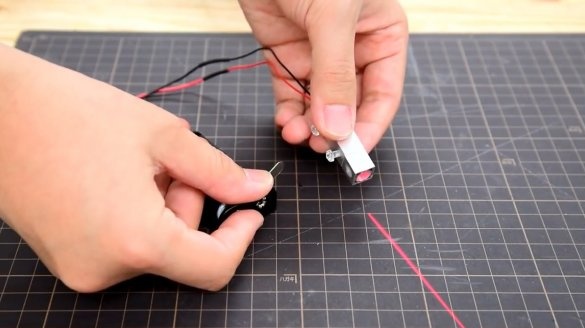

As you can see, the spot from the beam has an elliptical elongated shape, you need to make a mark on the module so that when assembling this spot lies perpendicular to the glass rod. This is important for getting a straight line.

Now the master rests the glass tube against the end of the pointer, and instead of a point, a very clearly visible, bright line appears.

He will make a case for a laser and a glass lens from an aluminum profile pipe 10X10 mm.

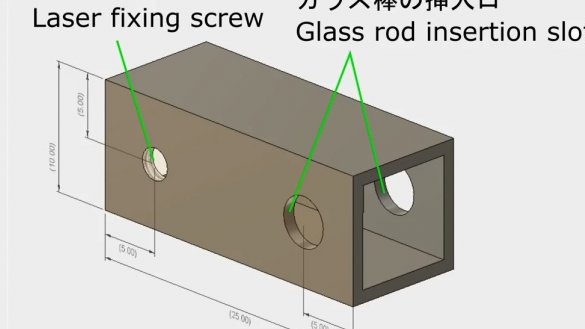

And here is a drawing of the case itself.

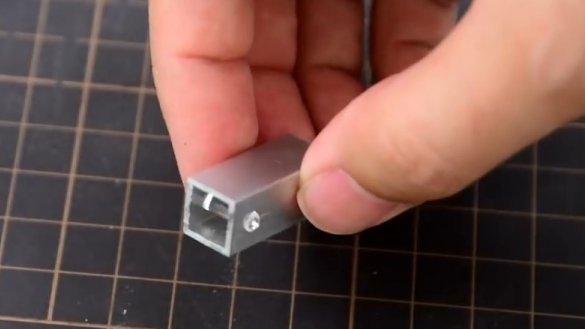

Drills holes for a glass rod, and an M3 clamp bolt. It is very important to make the holes for the lens strictly aligned.

Taps the M3 thread for the bolt with a tap.

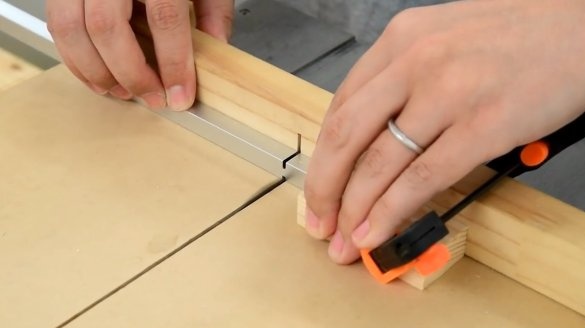

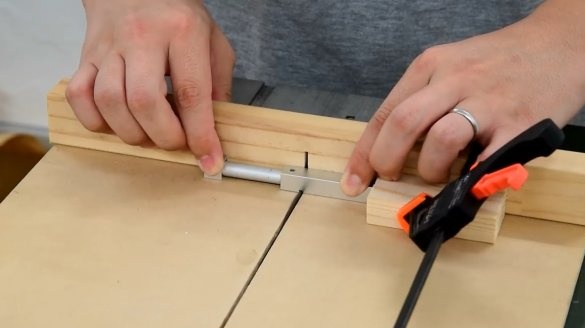

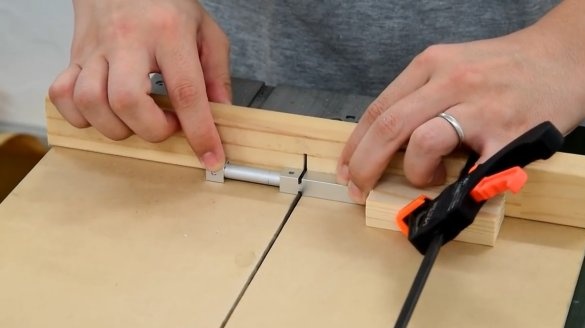

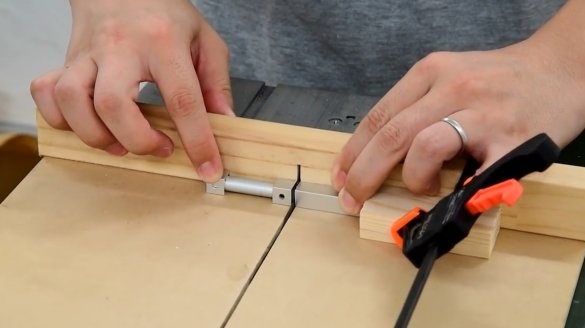

On a miniature circular saw, the cutting disc is slightly extended, sets the stop along the length of the workpiece, and fixes it with a clamp.

Pressing the end face of the workpiece against the stop, and turning it over makes cuts on the pipe from all sides.

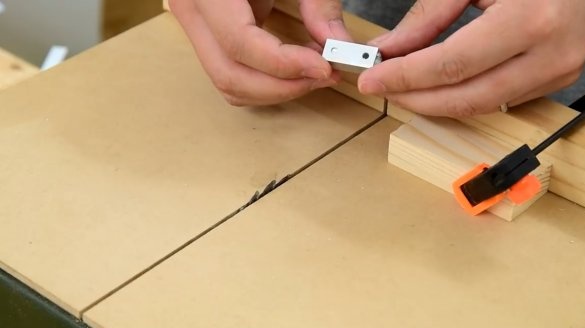

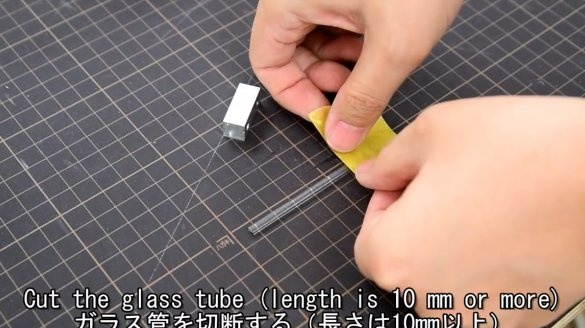

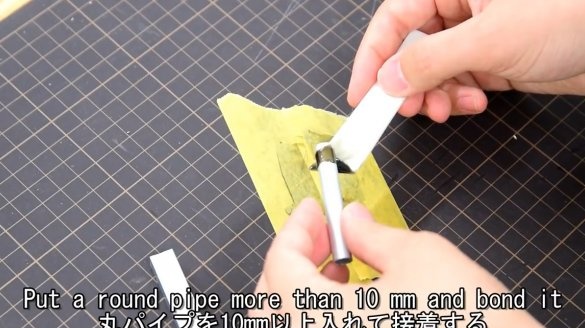

And here is a glass rod with a diameter of 5 mm. The author winds up one of its edges to a length of 10 mm with masking tape.

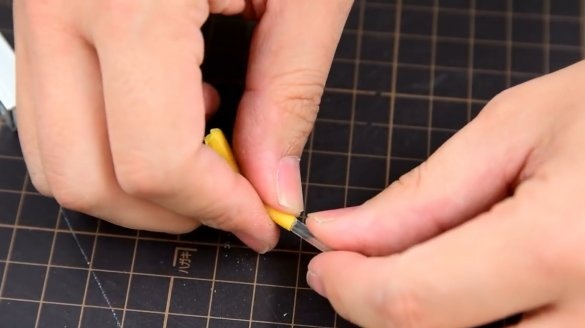

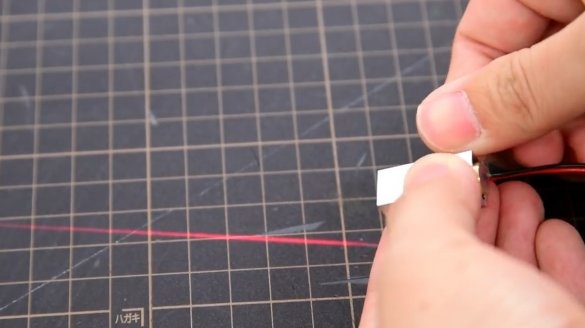

Then he makes a pair of cuts with a diamond file, and simply splits it in half.

The lens is almost ready, the author removes masking tape, and processes the edges of the chip with a file. After that, thoroughly cleans its surface with an alcohol cloth.

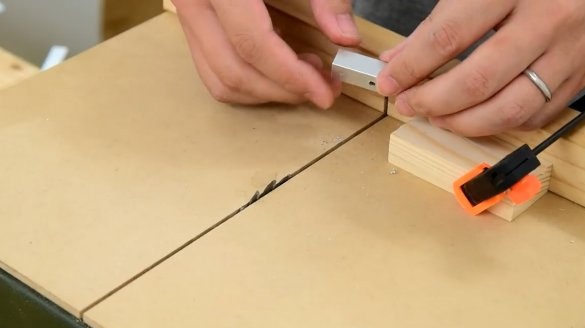

Holding the lens with a napkin, inserts it into place in the housing.

It mixes the components of epoxy resin, and lubricates the junction of the housing and lens from the outside. It is important that the resin does not get on the inside of the lens.

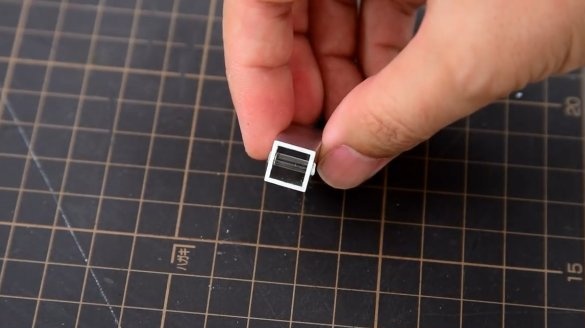

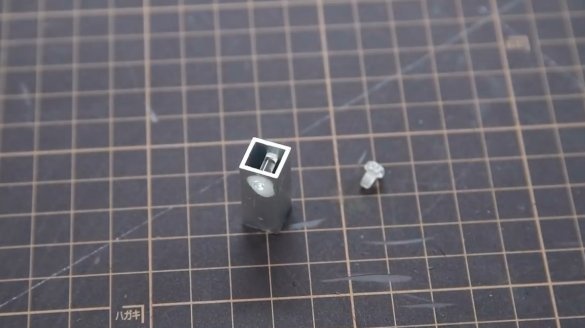

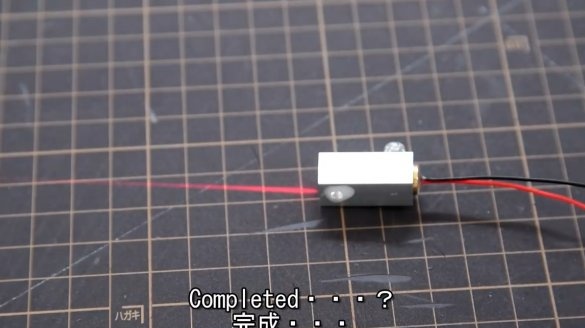

After polymerisation of the resin, the casing looks like this.

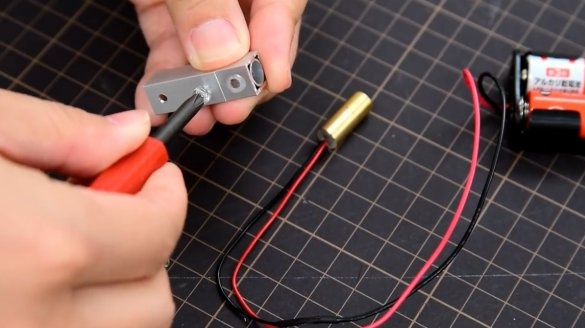

Screws in a plastic bolt, clamps the laser in the case.

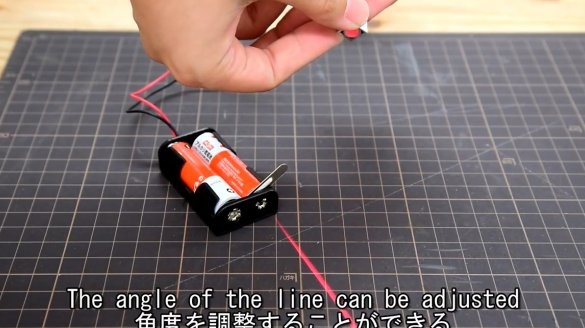

Then he achieves an even line, setting the axis of the ellipse of the laser beam perpendicular to the lens.

But, at a great distance, it became noticeable that the line is not perpendicular to the surface. Will have to finish it.

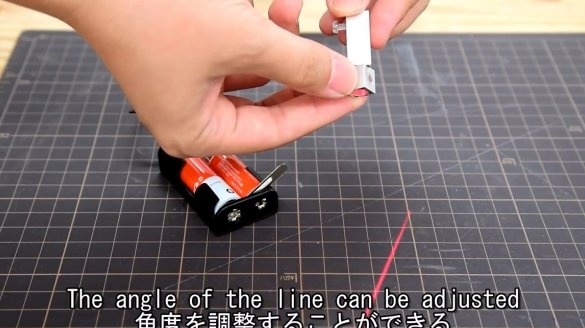

For improvement, the author needs an aluminum tube of 8 mm diameter, and the same square profile of 10X10 mm.

Using epoxy, glues the tube inside the square to a depth of about 10 mm.

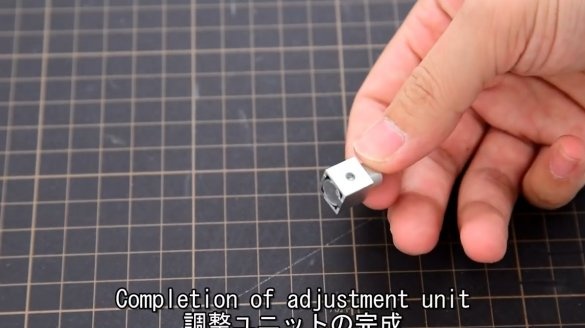

Strictly in the center drills a hole for the lens. Then he cuts off the adjustable head.

According to a familiar method glues the lens.

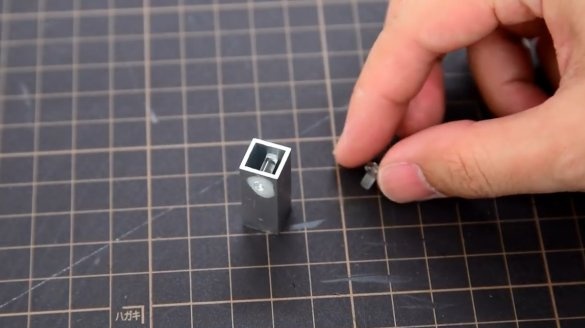

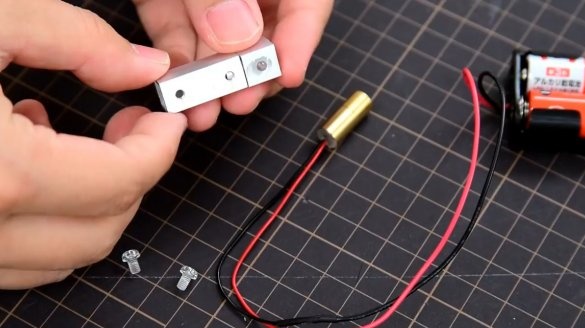

It inserts it into the case, clamps the laser and the head with bolts.

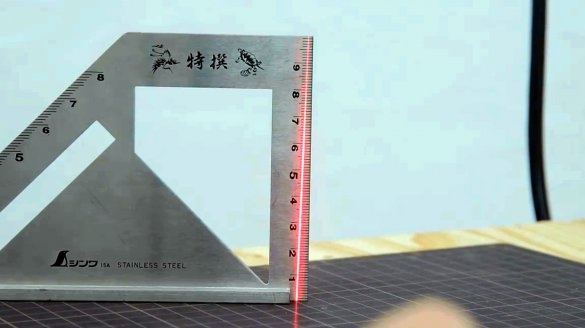

Now, by rotating the head, you can adjust the deviation of the line from the axis.

That's all! The device is ready to go. You can install!

Thanks to the author for a simple but useful tool for the workshop and at home!

All good mood, good luck, and interesting ideas!