Hello, dear visitors of the site!

Today I want to introduce you to my next homemade product, the idea of which I spied on this site. Specifically, then in this article: Screwdriver - do-it-yourself chuck holder.

I must say that I liked only the idea. The technical embodiment was not particularly liked.

Firstly, the author used a drill chuck. This is not entirely convenient for such an instrument, if only because a key is required for this cartridge! And at the same time you do not stick it with electrical tape to the cord so that it is always at hand, as I did in electric drills.))). That is, the key must always be worn with the tool and, at the same time, do not forget and do not lose! )) But with the latter I always have problems)))). In addition, the all-metal "key" cartridge has a fairly large mass !!! Accordingly, the center of mass of this tool with a light wooden handle will be shifted forward !!! This is also bad !!! ... But, the "half-plastic" self-tightening chuck from a screwdriver is better for this. He does not require a key, and is much lighter in weight !!! True, due to the smaller step of the working thread, it will have to be twisted longer, but this drawback can be neglected - because, basically, all the tools clamped into it for a certain type of work will mainly have shanks that differ little in diameter.

Secondly, fixing the "SDS-Plus" adapter in the wooden handle with glue also cast doubt on me. If I “hook” on turning, I’m sure that the adapter can crank !!!

And thirdly, if we make such a universal handle - then with the possibility of giving it with a hammer! Tol is, I would think of some kind of metal through axis in the handle, going out at the end.

I thought through all these points immediately after reading the article. And, as often happens, he “sincerely believed” that in time I would do something similar to myself, taking into account all these remarks ... Fortunately, several dead screwdrivers have already accumulated in the box. Yes, I would not have gathered ... Yes, here, in the manufacture of home-made machines, I had to drill a lot of holes in the metal. At the same time, on the other hand, at the exit, the drill leaves burrs that needed to be removed. He did this with a drill of much larger diameter.If you clamp in a screwdriver, then you have to very accurately control the time of "drilling" - I don’t need to countersink the hole !!! I just need to remove the burrs! ... Therefore, it is easier to manually turn the drill with a strong clamp.

And then I remembered about this tool, and decided to spend one evening on its manufacture.

And here is what I needed for this:

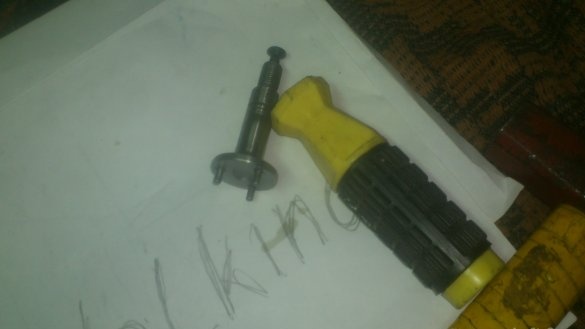

1. Self-locking chuck from a screwdriver.

2. handle from a broken screwdriver with a "ratchet".

3. Trim stud M12.

4. Cap nut M12.

5. Epoxy resin and hardener.

Having rummaged in a box with a broken power tool in search of a cartridge, I found just such a “piece of a screwdriver”.)))).

Once this poor fellow fell out of my hands at the time when I was hemming a roof in a two-story house. He didn’t survive the fall from such a height with a “beak” to the concrete blind area - the case scattered into pieces, the gearbox also fell apart in half and crumbled ... I didn’t resuscitate it - fortunately, I have more than one screwdriver on the farm. I just collected it and threw it in a box - let it serve as a donor for the rest.))))

He took off the cartridge. Why unscrew the screw (left thread ")

In this case, it was possible to easily fix the spindle and simply unscrew the chuck. But I didn’t want to go to a vise ... Therefore, I turned away the cartridge in the way that they are usually turned off on serviceable drills (when it is impossible to fix the spindle). He pinched a corner key into it and delivered a hard blow with a hammer on the end of the key sticking out to the side to “rip it off”. After that, he easily turned away the cartridge .:

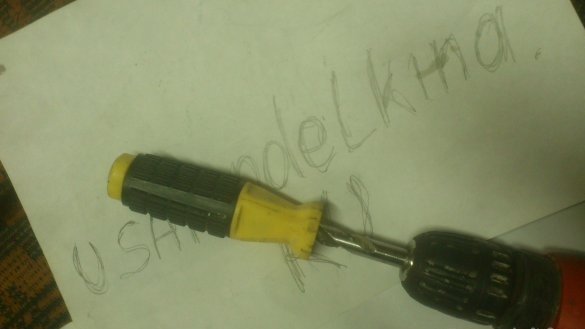

I did not make the handle out of wood (for the reasons described above). Rummaging through the junk, I found a broken ratchet screwdriver:

It was a tool from the category of “gift”, or “souvenir”, as I call them.)))) (You see what I'm talking about, right?))) This is when, for example, picking up a pair of pliers, you understand that if you now squeeze the hand properly - the handles, or the lips just crack)))). So the screwdriver was the same. And, accordingly, it broke at the first application ...

The adapter for "SDS-Plus" I also regretted spoiling ... I still have the spindle from the screwdriver:

So I decided to somehow adapt it to the handle:

First of all, with the help of a grinder, I cut off the faceplate with shafts for the planetary gearbox satellites. I do not need her.

In the "right scrap" I found the trimmer pin M12:

And welded it to the spindle trim:

The handle was inside the hollow. In the upper part it was closed with a cork. Perhaps it was meant that a stock of various bits would be stored inside.

With a 12 mm drill, I drilled holes in the lower end of the handle and in the plug:

The cartridge was screwed onto the spindle, and the pin was sharpened a little by the grinder on the sides to make its cross section “not quite round”:

This is necessary so that the pin does not rotate in the handle after I pour it with epoxy there.

Having put the handle on the hairpin with the cartridge screwed on it, I tightened the connection with the help of the FUM tape so that the epoxy did not leak into the slots.

I mixed the resin with the hardener using a cropped PET bottle as a container:

He secured the product in a vice, and poured the resin inside, previously protecting it from accidental dousing with the help of the legendary (blue) electrical tape:

Controlling the process of resin polymerization using the example of its residue, I waited until the resin became jelly-like and then removed the electrical tape and screwed the cap nut onto the stud, pressing the plug tightly into the resin.

So my tool is ready:

As already written, I initially did it for one operation - removing burrs from the back of the holes drilled in the metal, for which I clamped a large-diameter drill into it:

But, in the process, other methods of its application became clear. For example, holding a stepped drill in it, it is very convenient to drill large-diameter holes in sheet plastic:

And by installing a magnetic bit holder, you can get a fairly powerful screwdriver of any configuration. Of course, not as convenient as a simple screwdriver, but with rough work it helps a lot. (For example, recently dismantled old wooden racks and "tearing" large screws that a screwdriver could not "take", it was convenient with it. Also, in car she turned out of aluminum "boiling" steel screws "under the asterisk":

In general, with a balanced center of gravity, the tool turned out to be quite convenient. Very "graceful" and solid ..

And, although he doubted "in theory", in practice it turned out to be quite convenient to clip files into it:

And recently I discovered another clue. If you clamp a large self-tapping screw into it, we get a "technical corkscrew."

Of course, I’m not going to open the wine for them from the epic southern slopes, but here it is. And to get a piece of wood falling into the slot - too (I tried both of them))))

The tool, of course, is not for professional activities !! But here, it will be a good helper for us masters ... In the end, to hold a regular nail, quickly dig a hole somewhere (a hole is drilled, but a hole is picked)))).