Stages of making a casket:

- The main types of products

- Necessary equipment

- Materials for making papier-mâché

- Winding and gluing blanks of the body

- Pressure testing and drying

- Workpiece boiling

- Filing

- Hardware fittings

- Casket decarning

Materials for making papier-mâché

1. Cardboard (preferably binding). It should be clean, without glue and impregnation. In crafts in production, Balakhna cardboard is used, as the one that most meets all the requirements.

2. Starch paste in jelly consistency. It is boiled immediately before work.

3. Drying oil (linseed oil).

4. For the manufacture of accessories use:

a) brass sheet with a cross section of 0.5 - 0.7 mm;

b) a steel rod (wire) with a cross section of 1.5-2 mm.

The process of creating a box body begins with the manufacture of the base - a wooden beam, the so-called "blockhead". Its size is determined by the size of the “winding” - the future blank of the intended product. The length of the "block" is limited by the size of the press, and the cross section corresponds to the internal size of the product. It is made of dry, solid wood, preferably hardwood (birch or beech). Its surface should be smooth, without gouging. Ready "blockhead" is oiled so that it does not swell from raw "winding". It should go loose after crimping.

In addition to the "blockhead", we also need embedded parts - "cheeks" that compress the winding on it. The width of the embedded “cheeks” is greater than the width of the section of the “blockhead” by two wall thicknesses of the future building. The best material for the "cheeks" is chipboard. It has rigidity, providing the necessary crimp, while not being deformed. For uniform crimping of the workpiece, you need to have four “cheeks” - two mortgages with an exact size that takes into account the thickness of the workpiece, and two waybills that wrap around the bag (see Fig. 3).

For round blanks, a "blockhead" is made on a lathe. In extreme cases, bottles or jars that are suitable for the parameters can be used.

Oval and other soft forms of "boobs" are executed in a carpentry way according to the pattern.

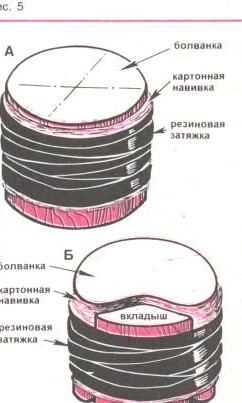

The manufacture of round and oval shapes is also carried out by winding several layers of cardboard on a blank, as well as on rectangular blanks, only crimping is done with a rubber band or strip with a tightening turn to roll (Fig. 5, a). The workpiece is held for 15-30 minutes in a clamp, and then released and removed from the blockhead. Further drying and more.

In the manufacture of complex shapes with concave surfaces, pads are used, i.e. wooden insert, compensating the pressure of the winding (Fig. 5, b).

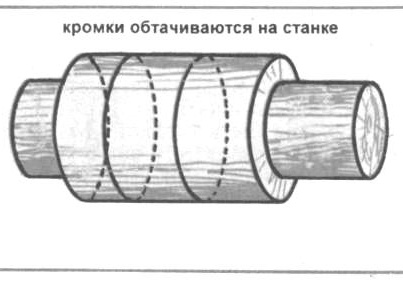

Round shapes are finished on a lathe (Fig. 6). First grind the trim (case), then glue the bottoms and bring the workpiece to the desired form.